Apr 16, 2024 | Petroleum

Attention all underground storage tank (UST) owners and operators in California! The State of California Senate Bill #445 requires owners and operators to permanently close or replace your underground tank containing hazardous substances not in compliance with new requirements by December 31, 2025.

This mandate, outlined in the California Health and Safety Code, chapter 6.7, section 25292.05, applies to all single-walled tanks and non-exempt single-walled piping.

This new law affects all single-walled tanks as well as those not designed and constructed by alternative fuels:

- Close the tank in place after being authorized by the board.

- Remove the tank from its site completely.

- Remove and replace the tank.

Loans and grants are available through the RUST program. RUST stands for Replacing, Removing, or Upgrading Underground Storage Tanks. This program is a system of grants and loans to help small business owners and operators come into compliance with regulatory requirements for underground storage tanks (USTs). Compliance is achieved through removing, replacing, or upgrading USTs.

The RUST program is a great way for small businesses to protect their business and improve their bottom line. By removing or upgrading their USTs, businesses can reduce the risk of environmental liability and save money on maintenance and repairs.

What Costs are Eligible for a RUST Grant or Loan?

Eligible costs for grants include:

- Costs for removing and replacing single-walled USTs and/or piping with doubled-walled USTs and/or piping.

- Costs for upgrades to USTs including installation of containment sumps, under-dispenser containment boxes/pans, and electronic monitoring systems.

- Costs for conducting enhanced leak detection tests.

In addition to what the grants cover, eligible costs for loans cover:

- Costs for corrective actions necessary to meet applicable local, state, or federal standards include, but are not limited to, any design, construction, monitoring, operation, or maintenance requirements adopted under the California Health and Safety Code.

Single-walled USTs have one wall between the petroleum fuel and the underground soil.

Double-walled USTs have two walls between the fuel and the underground soil. The second wall provides extra containment that helps to prevent leaks from reaching the soil. It is a tank in a tank (piping in piping) system.

Who is Eligible for a RUST Grant and Loan?

RUST Grant: Independently owned and operated small businesses with petroleum USTs and fewer than 20 full-time and part-time employees are eligible for a RUST grant.

RUST Loan: Independently owned and operated small businesses with petroleum USTs and fewer than 500 employees are eligible for a RUST loan. As with a grant, the principal office and business officers must be domiciled in California, and businesses dominant in their field of operation are excluded. All USTs owned and operated by the applicant comply with State UST regulations.

What Are The RUST Funding Amounts?

If you are eligible for RUST funding, you cannot begin work until you have a grant or loan executed by the State Water Board. The RUST program grants are available for between $3,000 and $70,000 per grant. A small business may receive multiple RUST grants, but the maximum lifetime limit in grant money for each small business is $70,000.

Next Steps:

Are you considering replacing, removing, or upgrading your underground tank? Please reach out to our tank experts today by emailing sales@nwpump.com, calling 1-800-542-PUMP, or finding the nearest location to you here.

Apr 12, 2024 | Industrial

Loading materials in and out of facilities is both vitally important to production and at risk of sudden, expensive accidents that threaten to stop production altogether. Bulk loading keeps facilities functioning whether a facility is moving petroleum for fueling or raw materials like dairy for food manufacturing. Safety & efficiency are vital to maintaining everyday operations. Northwest Pump is a provider of premier bulk loading solutions to maintain the highest levels of safety and efficiency for our customers’ needs.

Industries We Support

Bulk loading equipment comes in a variety of styles, materials, and designs for optimal performance depending on the application. Northwest Pump works with OPW to provide bulk loading equipment for chemical applications, industrial manufacturing, food & beverage manufacturing, pulp & paper manufacturing, rail & truck transportation, and fleet fueling.

Bulk Loading Equipment

Pumps & Air Compressors

Pumps are essential for bulk-loading applications, whether for liquids, gasses, or even solids. Northwest Pump offers a wide range of products to meet all your bulk loading needs, such as air compressors, fueling pumps, corrosive duty pumps, sanitary pumps, and more.

Blackmer’s vane pumps are the undisputed champion of fuel transfer. Offering unbeatable reliability and top-of-the-line performance, Blackmer is the clear choice for any fuel transfer job. The sliding vane technology behind Blackmer’s vane pumps ensures continued, consistent performance for each pump’s lifetime, even after the vanes wear out and need replacement. The SGL series Sliding Vane pumps from Blackmer use ductile iron for their construction to add another layer of protection for the pump to extend its lifespan working with corrosive materials. Another reason to use Blackmer for liquid transfer is its line-stripping capabilities. Even working with petroleum, Blackmer’s vane pumps can adjust the suction power to extract the remnants of fluids within the piping and the tank, improving your output without substantial changes to your pump system.

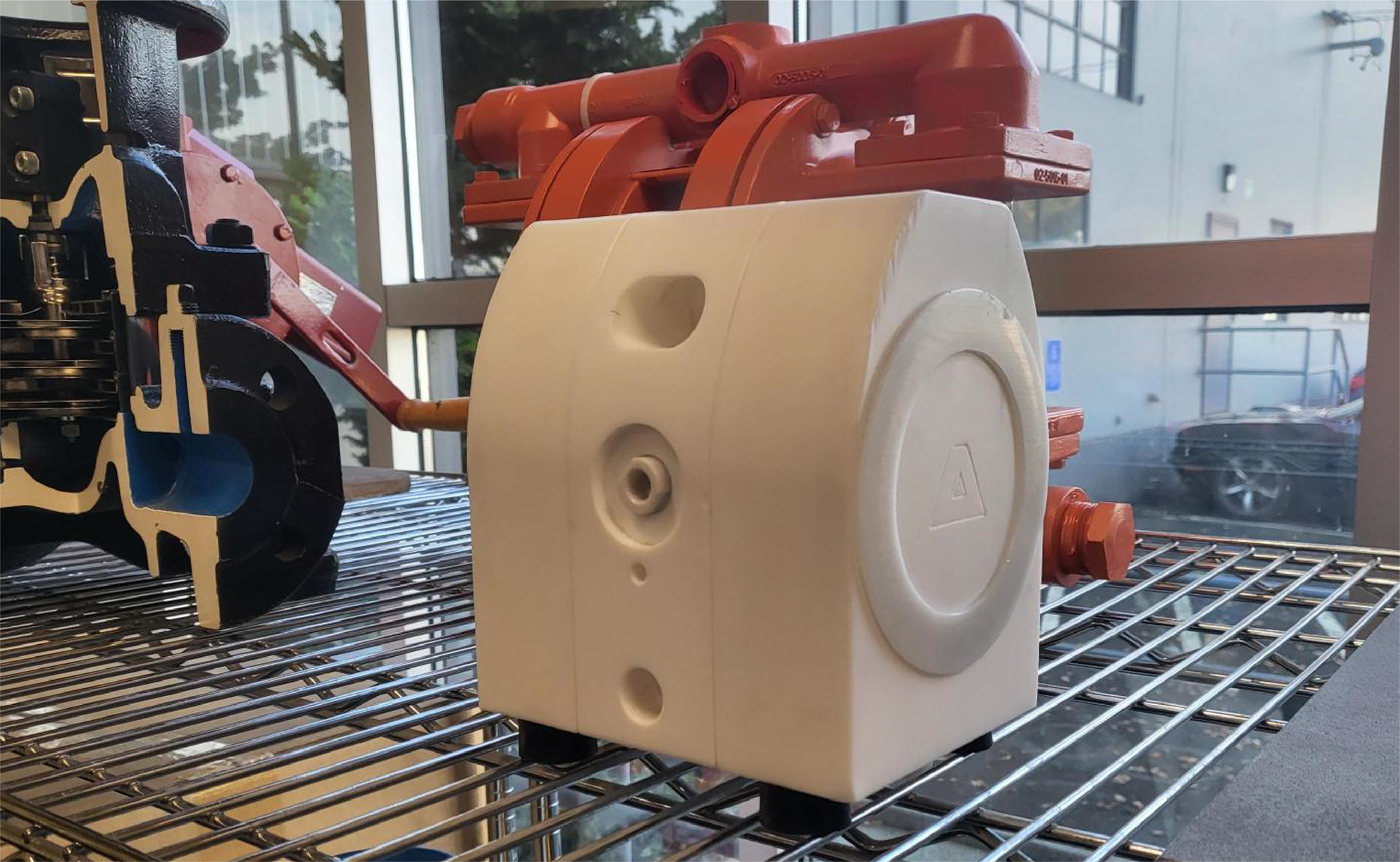

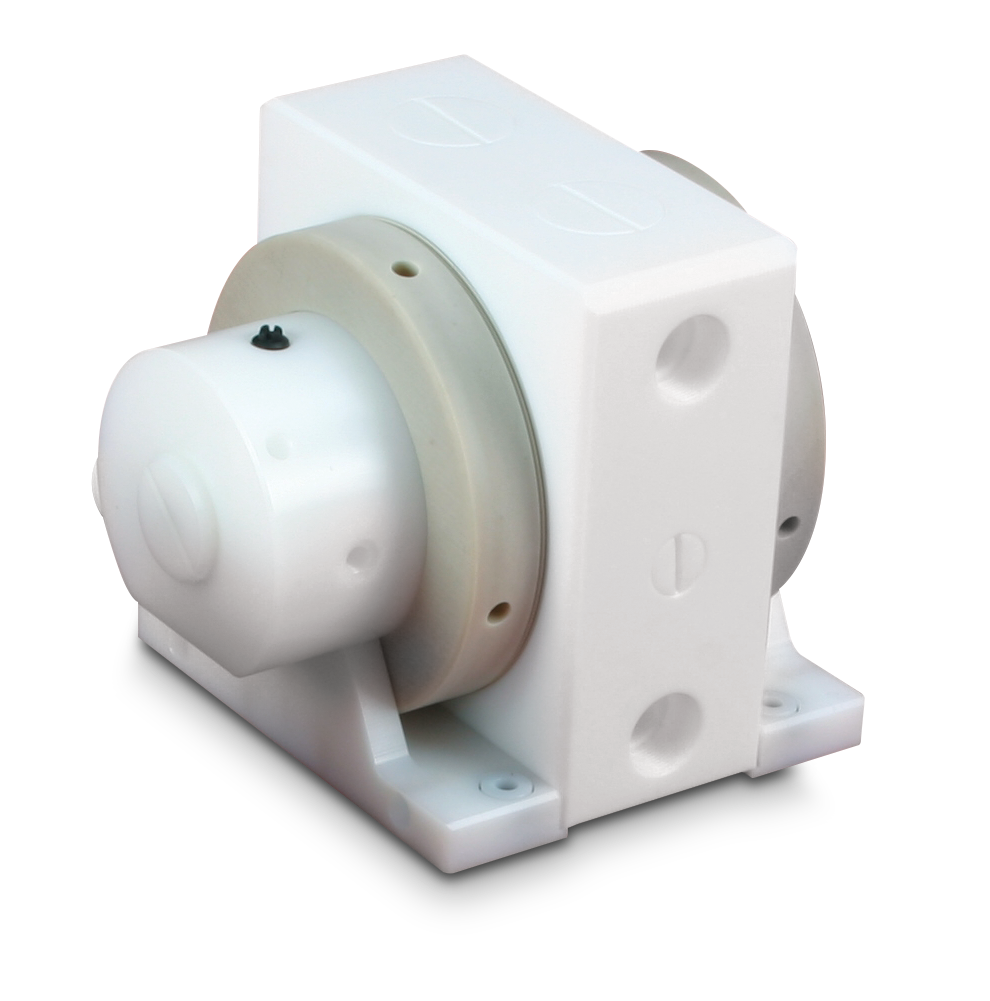

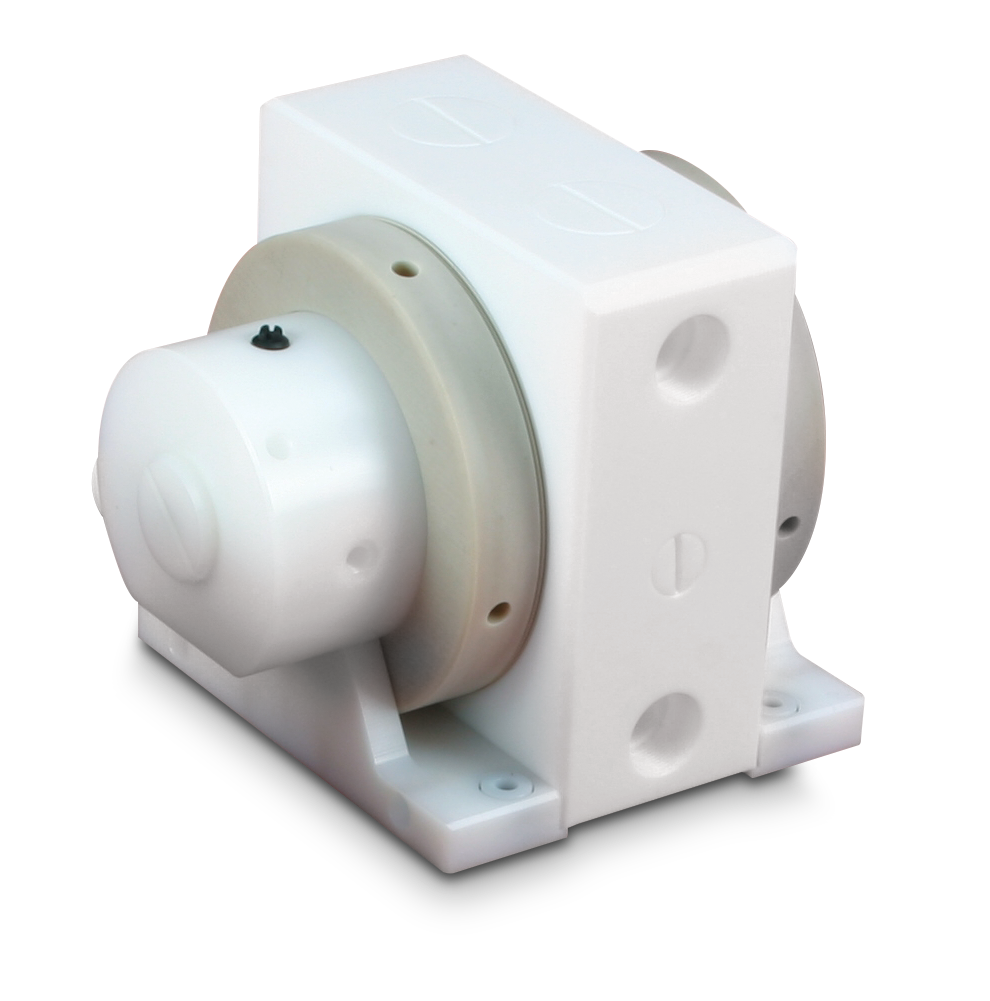

Finding the right chemical duty pump can be challenging to balance the chemical compatibility of the materials and the pump’s lifespan. Almatec provides cutting-edge chemical transfer with its PTFE-carved AODD pumps. No metal in the wetted housing means that this pump withstands the harsher chemicals it encounters and makes it a quintessential choice for industries like Semiconductor manufacturing.

For solid material transport, air compressors replace pumps in loading systems. Compressed air provides the force to move materials like flour, sand, or bitumen on and off trucks or trains. For stationary applications, Sullair provides state-of-the-art rotary or centrifugal compressor options to move solid materials where they need to be.

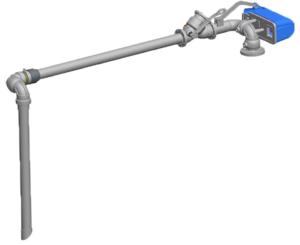

Loading Arms

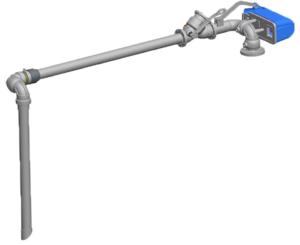

OPW offers custom-built loading arms to match your exact needs. Our team works with you to determine the specifics of your application, the size and style of the arm, and the deadline your facility needs to meet your delivery and quality expectations.

These loading arms are versatile, and are either top or bottom-loading, depending on the material being transported. They come with different support options such as fixed, gas-strut, and fully supported with jack-knife storage options. The piping size varies from a two-inch diameter to a four-inch diameter for top-loading styles. For bottom-loading styles, the range goes from a two-inch diameter to a six-inch diameter. OPW offers loading arms in three materials – carbon steel, stainless steel, and aluminum – to suit different industrial needs.

Hoses, Couplings, Swivels, and other Accessory Equipment

To complete your brand-new bulk loading system from OPW, they also offer the accessories connecting the pumps to the loading arms including hoses, coupling, swivels, and even hose sleeves from start to finish. These products have API certification for quality assurance and give you peace of mind. To prevent product loss in case of accidents, OPW provides breakaway couplers and smart hoses in addition to the standard options. OPW’s couplers, such as the Lynx API Series Bottom-Loading coupler, come with a simple one-pin-style opening mechanism to simplify repairs when they are needed.

Safety Equipment

Loading sites are RIFE with opportunities for workplace injuries. Northwest Pump has partnered with SafeRack to provide OSHA-compliant safety equipment solutions including gangways, fall prevention systems, ladders, and more to protect our customers and their workers from these risks.

Gangways

SafeRack offers three main gangway styles: flat ramp, flat ramp telescopic, and self-adjusting stair. Telescopic gangways extend beyond the standard flat ramp-style gangways for flexible access with additional protection. SafeRack uses aluminum, stainless steel, or galvanized steel to build the gangways, with rubber bumpers and stainless steel quality bearing rods to ensure the integrity of the designs. Depending on the application, the gangway can be as thin as two feet wide up to six feet. Optional mounting universal angling clips are also available for these gangways.

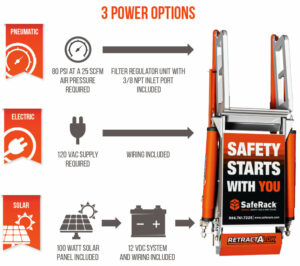

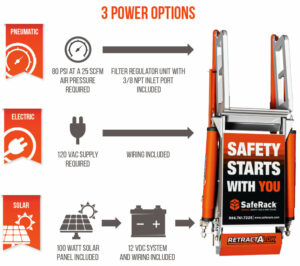

For additional security when using these gangways, SafeRack offers the Retractalok. The Retractralok is a plug-and-play solution that eliminates the springs and their associated failures while lifting and lowering gangways to their desired height. It offers an automatic lock to prevent manual overriding when the gangway is in use. Retractaloks have three power options to best suit a variety of facilities, air-powered, solar-powered, and standard electrical plugin.

Fall Protection/Arrest Systems

Whether looking to prevent a fall entirely or arrest it prematurely, SafeRack offers complete systems to protect your workers where the risk is greatest. From harnesses to complete articulating safety platforms, SafeRack offers fall prevention and fall arrest solutions.

Mobile Access Units

The Mobile Access Unit – Industrial Model, or MAUI, is a mobile access platform designed for dependability, flexibility, and safety. MAUI offers a telescoping ladder to access the different heights and needs required. This comes in handy especially when working with both trucks and rail applications. MAUI comes with solid rubber tires, preventing ill-time flat tires, and even an ATV option for rough, unsteady terrain.

Next Steps

Looking for solutions for your next bulk loading system? Northwest Pump has the tools for the job. Reach out to begin designing your custom system with our team of experts using the Contact Us button below. For service needs on your current pumps & air compressor equipment, request service using the button on the right.

Mar 19, 2024 | Petroleum

In the ever-evolving landscape of small businesses, staying ahead of the curve is crucial for success. Introducing JUXTA Nomad, an unstaffed, portable turnkey retail solution. Nomad takes you beyond brick-and-mortar with the highest profit per square foot retail format in the world. Nomad is not just a retail solution; it’s a game-changer for businesses looking to expand without the traditional barriers.

With minimal time commitment, a cost-effective model, flexible location selection, and impressive profit margins, Nomad is redefining the rules of retail expansion. Embrace the future of retail with Nomad and watch your business soar to new heights.

Nomad offers an incredibly low operating expense profile with no full-time staff required courtesy of its AI-powered sensor fusion design. With it delivers exceptional topline revenue per square foot with an optimized targeted retail offering of roughly 500 SKUs. Created with portability at its core, you can operate anywhere your consumers are without a multi-decade commitment to one location.

One of the unique features of Nomad is the flexibility it provides in location selection. Unlike traditional retail models, Nomad turns location decisions from permanent choices into flexible, short or mid-term investments. This agility enables businesses to adapt to changing demand or capitalize on better opportunities, allowing them to pick up their store and chase demand wherever it may lead.

Potential locations include hospitals, EV charging stations, festivals, campsites, tourist attractions, and college campuses. The internal layout of the JUXTA Nomads is limited solely to retailing typical convenience store items, but the format can stock whatever the retailer wishes.

Nomad boasts the lowest operating expenses of any retail store format. By carefully selecting the top 500 products, businesses can optimize their inventory and streamline operations, turning the typical 2-4% operating margin into an impressive 10%. Some retailers may even see operating margins as high as 20%, unlocking unprecedented profitability in the retail sector.

How It Works:

Tap– Your consumers access Nomad with standard payment methods. With no need to download an app or be a member, shoppers simply use the credit, debit, or mobile wallet already in their pocket.

Shop – Consumers feel right at home because shopping works just like a traditional retail store. While they take anything they want, their AI computer vision system and advanced shelf sensors track shopping behavior and add items to their basket in real time. The information is combined in the cloud to create a digital basket for each customer. JUXTA’s AI-driven technology will collate their purchases if a family or group of shoppers enter the store.

Review– To provide assurance and comfort in an unstaffed environment, consumers have the option to validate their purchase in real-time on a proximity-based checkout screen and request a digital receipt. Receipts are delivered in less than a minute of leaving the store.

Leave– Consumers in a hurry, can simply leave whenever they’re ready, and they’ll be charged for what they’ve taken.

Next Steps:

Curious about the potential impact on your business? Take the next steps with JUXTA and start your low-risk growth journey by contacting our experts at Northwest Pump by emailing sales@nwpump.com, calling 1-800-452-PUMP, or finding the nearest location here.

Mar 14, 2024 | Industrial, Services

One common pain point for manufacturing plants is repeated pump failure in and around washdown applications. Facilities risk losing tens of thousands of dollars when using equipment not meant for washdown. Whether preventing a failure before it happens or troubleshooting existing washdown equipment, our team of pump experts, engineers, and service technicians can help with washdown needs in your facility.

What kind of facilities need washdown equipment?

Washdown processes are not necessary for every industry. The three industries that typically require washdowns are food & beverage, marine, and those working with heavy-duty chemicals. Without these features, corrosive chemicals or bacteria can damage washdown equipment. This is especially true for marine applications with seawater and bacteria ever-present.

What kinds of pumps are best for washdown applications?

Because of the specific industry-specific needs for washdown applications, pumps designated for washdowns need stainless steel for the wetted housing or use a sanitary-grade industrial coating. Both prevent untimely wear and tear on the pump itself.

The two most common styles of pumps for washdown applications are centrifugal and air-operated double-diaphragm (AODD). Centrifugal pumps are some of the most common on the market because of their pressure-boosting capabilities and the tendency towards higher flow applications. AODD pumps, on the other hand, have a significant advantage in washdown applications: the motorless design prevents the leading cause of pump failure during washdowns.

What is a motor washdown rating & how important is it?

The biggest concern when working in washdown applications is not the style of a pump but the motor. Washdown-rated motors protect the fragile electrical components against the large volumes of water required for these types of applications. A standard motor is prone to rust or water leakage into the electrical components that enable the pump to run, making it unsuitable for washdowns. Additionally, long-coupled pumps will require a washdown-rated coupling guard to protect the coupling element from water damage.

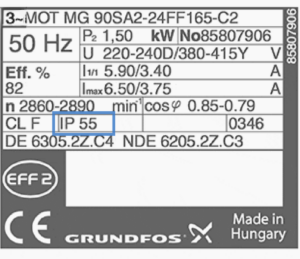

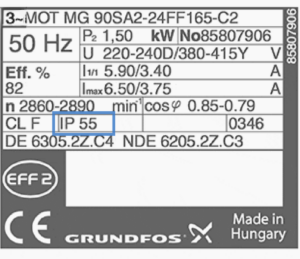

The International Electrotechnical Commission (IEC) designed an Ingress Protection, or IP, rating system to specify how a motor’s enclosure protects from outside contaminants. Manufacturers display the IP ratings on the motor tag and in the motor’s manual. This rating uses two numbers, each representing how it blocks solids or liquids. The first digit will be a number from 0-6, and this scale represents how this enclosure will prevent solid objects from reaching the internal mechanisms. The second digit scales 0-9 to indicate how the enclosure prevents liquids from interacting with the electrical components. Motors with no protection against dust or water would have an IP00 rating. Conversely, a motor with an IP69 rating indicates protection from dust and water resistance even while submerged in shallow water. Typical washdown applications have IP ratings ranging from 55-69, depending on the spray pressure.

Do I need another pump to boost pressure for washdown?

While having pressure booster pumps or pump skids in addition to the washdown pumps is not uncommon, not all washdown applications require increased pressure. Facilities with multiple washdown systems in place or far away from their local water utility distribution system will likely benefit from installing a booster system in addition to their existing washdown equipment.

Our Washdown Equipment Vendors

Pump Vendors

Grundfos

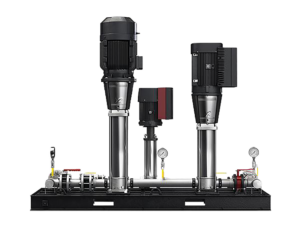

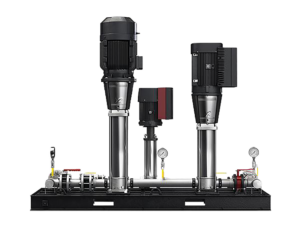

While pumps are not the pain point in washdown needs, Grundfos sets itself apart for washdown equipment with the Hydro HP pump system. The Hydro HP is not one single pump, but a complete assembly of in-house manufactured CR/CRN pumps, washdown-rated motors with an equivalent IP 66 rating, and automation & real-time monitoring accessories applied to a baseplate ready to connect to your existing pump system.

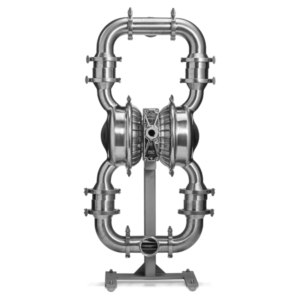

Wilden

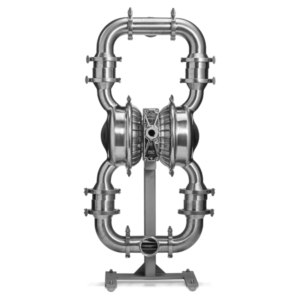

These industry-renowned AODD pumps take the hassle out of maintenance. Since AODD pumps do not require a motor, they stand out as an option for washdown applications. Wilden builds its AODD pumps with as few parts as possible to simplify assembly & disassembly of the pump. The Saniflo series from Wilden features stainless steel construction to prevent bacterial growth during periods of non-use, maintaining the washdown-standard design.

Motor Vendors

WEG

WEG offers washdown-rated motors with IP56 or IP69 ratings to fit your needs. This vendor manufactures durable equipment with a patented three-stage sealing system to ensure a watertight fit. To validate this claim, WEG offers a substantial motor warranty with protection for up to twelve months from the installation date or twenty-four months from the assembly date listed on the motor tag.

Baldor

Baldor offers motors with IP ratings up to IP69, including a specific Food-Grade motor to keep with sanitation standards set by the FDA. These motors also offer a ‘footless’ CIP-in-mind design to reduce the surface area for cleaning.

Custom-Built Washdown Pump Skids

Northwest Pump

For those looking for precision control for their washdown needs, Northwest Pump offers custom fabrication services through our Industrial Service Division to create the washdown pump skid you need. Whether you supply the plans or let our engineers lend a hand, our service technicians work with you to build to your specifications.

Next Steps

Are you in search of the perfect washdown solutions for your facility? Look no further! We can provide the most suitable washdown solutions to meet or even exceed your requirements. Trust us to deliver a top-notch solution that leaves your facility sparkling. Contact us below to get started.

Feb 15, 2024 | Petroleum

Gas station floor protector mats have become essential in maintaining the longevity and safety of gas station flooring. These mats have been designed to meet various needs, with a focus on gas station environments. At gas stations, sites are prone to spills of fuel, oil, and other chemicals. Each circular mat has been specifically designed to resist these substances, offering effective protection for the underlying flooring. This not only preserves the aesthetic appeal of the station but also prevents long-term damage.

Covering a sump with durable gas station mats will prevent rainwater and other potential contaminants from leaking inside, as well as protect the grate from physical damage. These mats are made from all-weather SBR rubber and reclaimed rubber, which means they can be left outdoors and provide outstanding protection, rain or shine.

Gas Station Mat

This gas station mat is crafted to provide superior floor protection at gas stations. Its durable rubber construction is designed to withstand heavy foot traffic, vehicle loads, and harsh weather conditions. The mat’s anti-slip properties ensure safety for both staff and customers, making it an ideal choice for gas station settings.

Specifications:

- Product: 07-101-GAS-9

- Size: 4ft. in Diameter

- Thickness: 9mm

- Weight: 26 lbs.

- Materials: SBR and Reclaimed Rubber

- Color: Black

Diamond Grip Gas Station Mat

For those seeking enhanced traction and a distinctive design, the Diamond Grip Gas Station Mat is just that. This unique diamond pattern not only adds a visual appeal but also enhances slip resistance. The mat’s durability remains a key feature, making it suitable for high-traffic areas, including gas station entrances and fuel pump zones.

Specifications:

- Product: 07-101-GAS-6MM

- Size: 54″ Diameter

- Thickness: 6mm

- Weight: 20 lbs.

- Materials: Vulcanized Rubber

- Color: Black

Durability: Both mats are engineered to endure the rigors of daily use, providing long-lasting protection for your flooring. This rubber is a low-maintenance product that is very easy to clean. For best results, simply use a wet cloth or a mop with a simple commercial cleaning solution. Please do not use caustic cleaning agents such as bleach.

Anti-Slip Properties: Safety is a top priority, both the Gas Station Mat and Diamond Grip Gas Station Mat offer excellent anti-slip features to prevent accidents in busy gas station environments. Slip resistance and safety are a top priority in gas stations, where spills and wet conditions can pose risks. These floor protector mats provide a secure surface for both customers and staff. The textured design enhances traction, minimizing the chances of accidents.

Easy Maintenance: Designed for convenience, these mats are easy to clean and maintain, ensuring a hassle-free experience for gas station owners and operators.

Versatility: While specifically designed for gas stations, these mats can also be used in other high-traffic areas where floor portion and safety are paramount.

Maintaining a clean and presentable gas station is crucial for customer satisfaction. These mats are easy to clean and maintain, requiring minimal effort to remove dirt, debris, or any type of spill. Their low-maintenance nature contributes to a hassle-free upkeep routine. While these mats are designed for gas stations, they find applications beyond fueling areas. The mats can be utilized in service bays, car washes, and other high-traffic areas. The versatility of these mats makes them a cost-effective solution for various spaces.

Next Steps:

The Gas Station and Diamond Grip Mats stand out as reliable solutions for maintaining clean, safe, and visually appealing flooring in gas station settings. Additionally, whether you prioritize classic durability or desire a unique diamond pattern for enhanced grip, these mats cater to a variety of needs. Explore the benefits and make a smart investment by contacting our team today!

Feb 14, 2024 | Industrial, Services

Clean compressed air correlates with producing higher-value merchandise, reducing recalls, and increasing downstream equipment performance. Quality testing is an effective tool to understand the cleanliness of your compressed air. Regulations usually only mandate annual tests, especially for food & beverage manufacturers. However, compressed air experts recommend testing at least once a quarter to maintain the highest compressed air quality.

Testing is essential to understanding your facility’s air quality. Poor results and delayed corrections can severely impact your facility. Knowing what to expect and preparing in advance will help avoid issues with your next audit. Here are some frequently asked questions and solutions to help you prepare accordingly.

How do I test my compressed air quality?

Third-party compressed air auditors use state-of-the-art laboratories to conduct precise quality testing. One benefit of working with air auditors is that after the process, auditors can automatically validate the quality of your air; there are no additional steps needed to prove compliance with ISO 8357. Rather than dismantling your entire compressor system and sending it off-site for inspection, air quality testing facilities send sampling kits to gather samples from the nearest air outlet. While each kit will differ from the other, a completed kit should have a bottle of air from your compressor system ready to be sent out.

Our trained service technicians can gather your air testing samples without risk of contamination. Upon request, your Northwest Pump compressor tech will take an air sample for you during any routine maintenance appointment. They take samples at point-of-use and at the compressor to give customers the best insights into their compressed air quality. Our technicians will alert customers of contamination risks before taking the air sample. From there, our service division works with third-party certified air auditors to analyze and validate your sample.

What Happens During Compressed Air Quality Testing?

For a complete outlook on the quality of your compressed air, auditors will conduct several tests on the air sample provided. While different testing methods can vary, the most common are:

- Laser Particle Counters

- Filter Microscopy

- Gravimetry

- Viable Microbe Sampling

- Water Vapor Testing

- Oil Testing

- Oil Aerosol Testing*

- Oil Vapor Testing*

Combining the above tests is the best way to ensure that your air meets the ISO 8357 requirements that you may need. Each test does not necessarily focus on every component of ISO classification. While you could only have one specific test done at a time, multiple tests give you a better understanding of your air quality.

*Before testing your compressed air for oil, or hydrocarbons, it is important to ensure that the test can detect oil in both vapor and aerosol forms. Some testing services or solutions on the market only check for one variation of oil in compressed air samples, which could give a misleading result.

How Clean Should My Compressed Air Be?

Whether your air should reach a specific ISO classification or not will depend on your facility’s air needs and usage. Industries such as food & beverage, pharmaceutical, and semiconductor manufacturing, require high purity in their compressed air. These industries will also need to meet the standards set by governing bodies like the FDA before continuing production.

As mentioned earlier, there is a direct correlation between cleaner air and higher-quality products. Compressed air for general uses may not need to be of a higher quality. Alternatively, process air is meant for smaller-scale, specific applications, and may have more direct contact with products. Facilities may want to invest in instrumentation for higher-quality compressed air.

What Can I Do to Improve My Air Quality?

There are several ways to improve air quality before completing any compressed air quality testing. Below are a few suggestions sorted by efficacy and the length of implementation time.

Short-Term Solutions

One of the fastest ways to improve your compressed air quality is to change out the filters in your air treatment equipment. This will remove remnants of dust, dead bacteria, or other debris that could eventually leak through to the point of use. Regularly changing your air filters can also solve issues such as pressure drop further downstream.

Another quick way to improve the quality of your compressed air is to ensure that your machines have regular service. Regular service is an easy way to ensure your compressor system works as it should. Our rotating equipment service plans also include regularly changing out all filters on your compressors.

Mid-Term Solutions

If you want a significant improvement in compressed air quality, upgrading your air treatment equipment could be a worthwhile investment. This solution can provide greater improvements than service appointments, which can only do so much. Upgrading your filters, dryers, or condensate drains allows you to better match current production goals and even future needs. You should choose filters that are easy to clean and can withstand high-temperature steam to eliminate microbial contaminants.

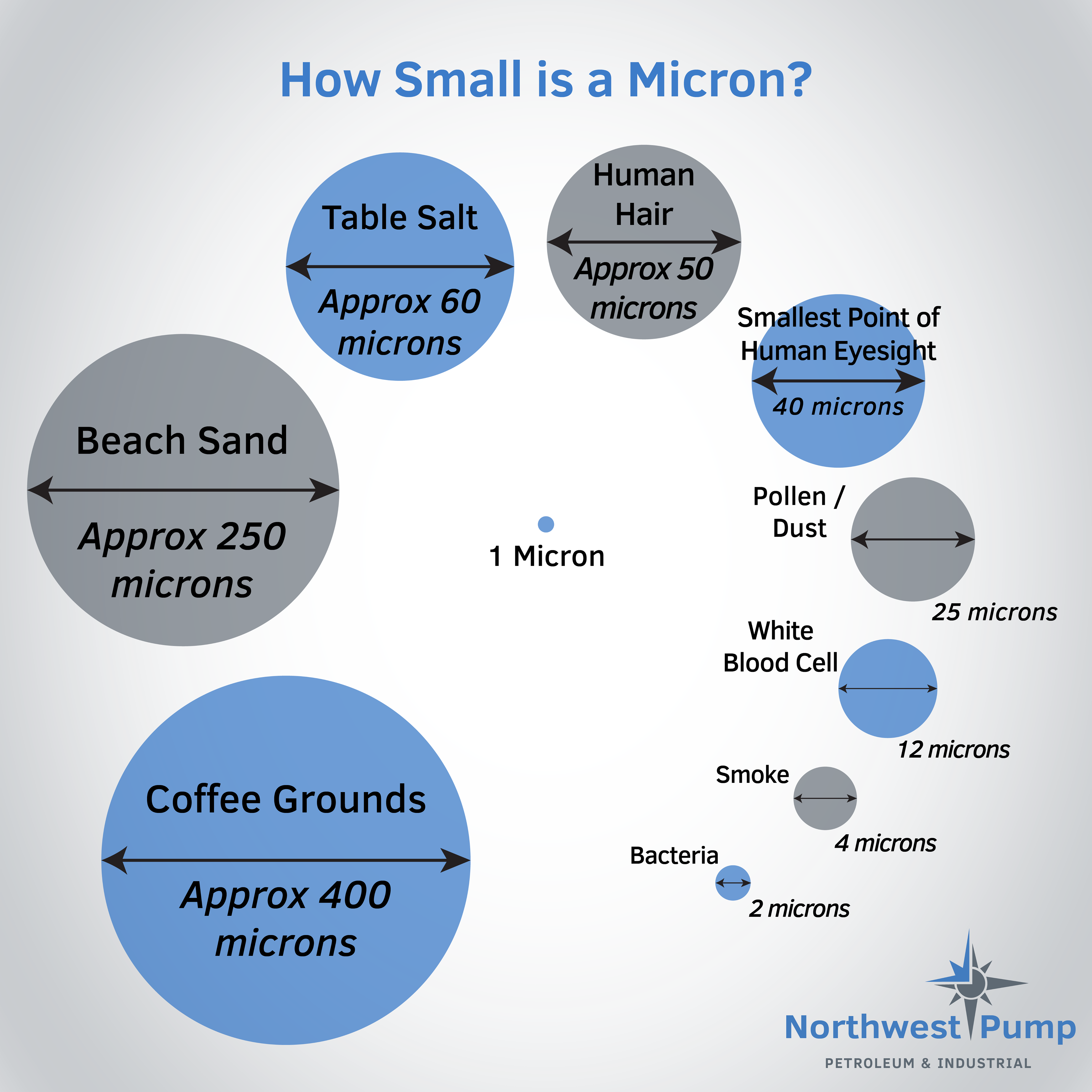

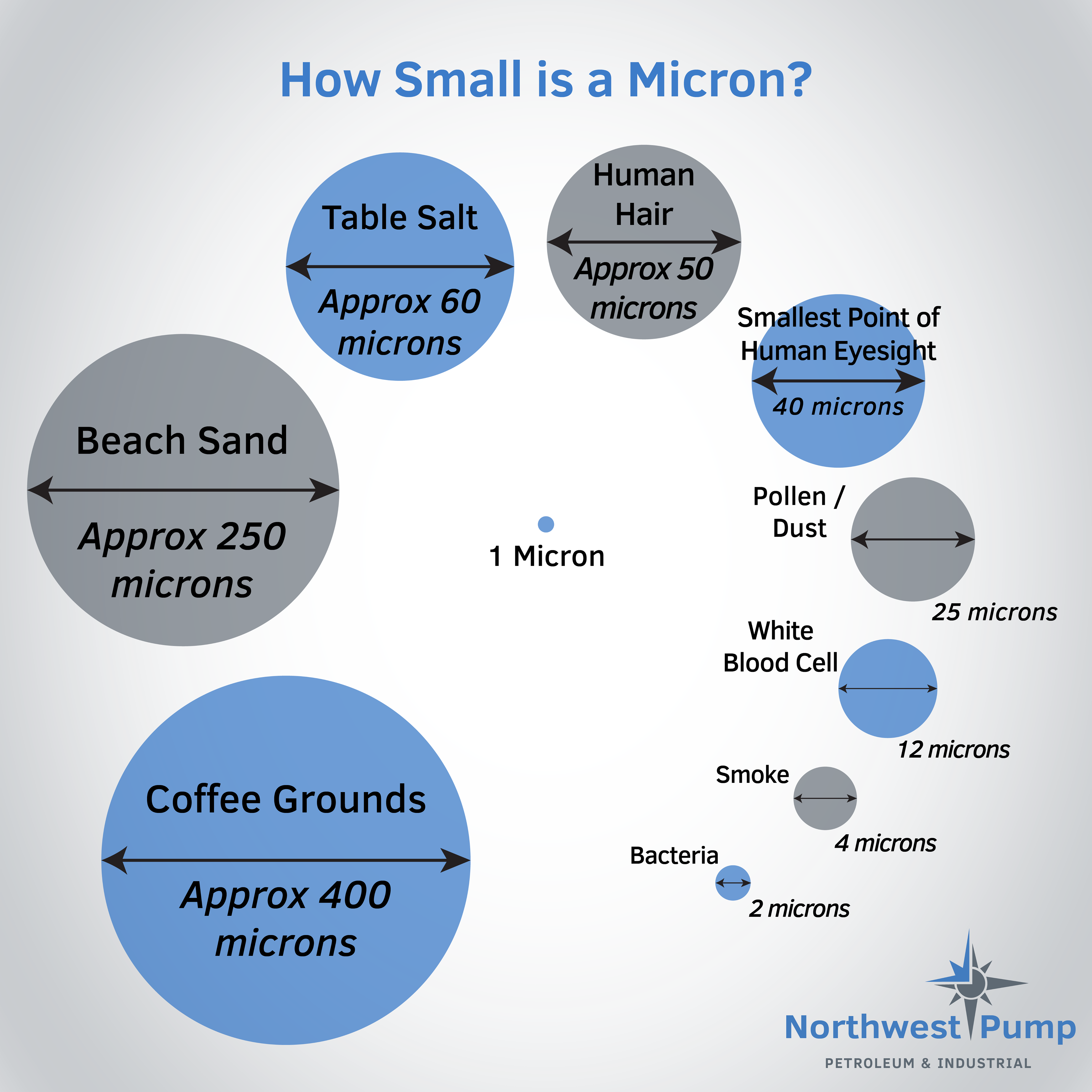

For high-purity applications, facilities may require multiple filters to target each type of contaminant, such as dust, microbes, moisture, and oil. We recommend investing in filtration equipment from Parker and Sullair. Both brands offer filters as small as .01 microns to catch even the smallest bacteria before it reaches the point of use.

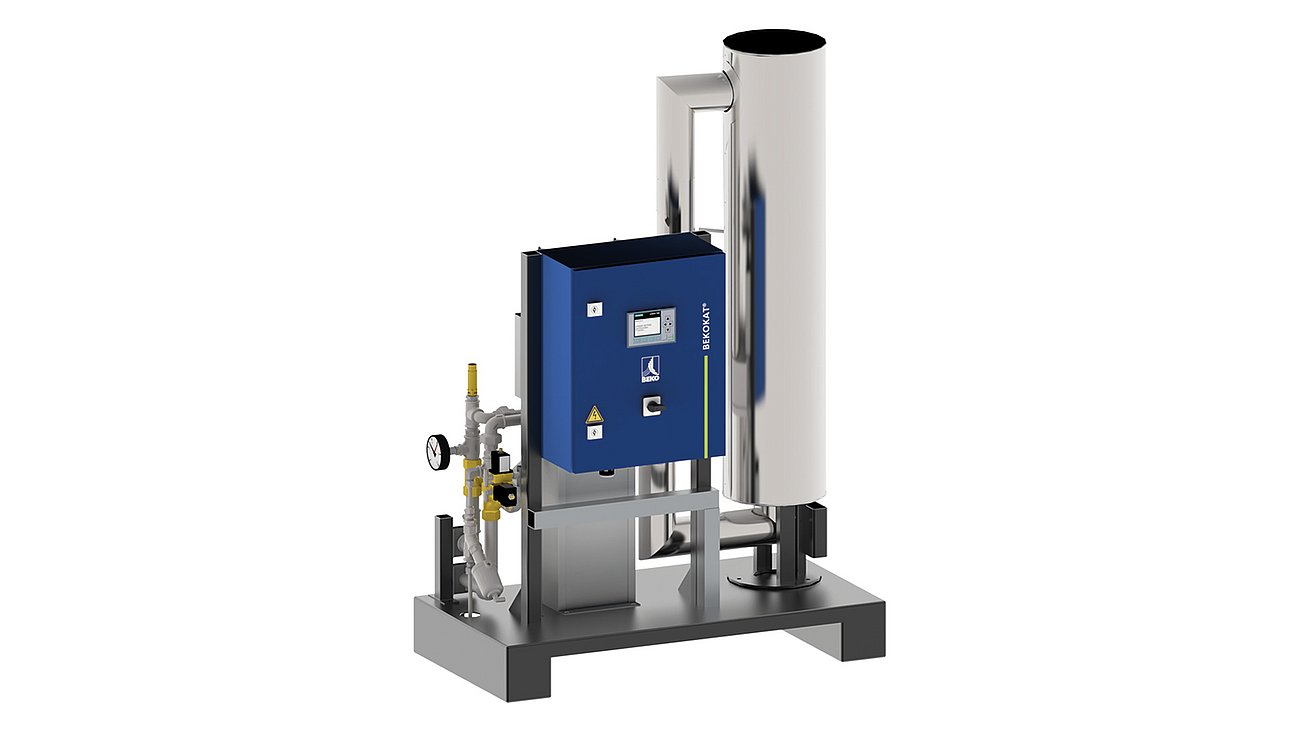

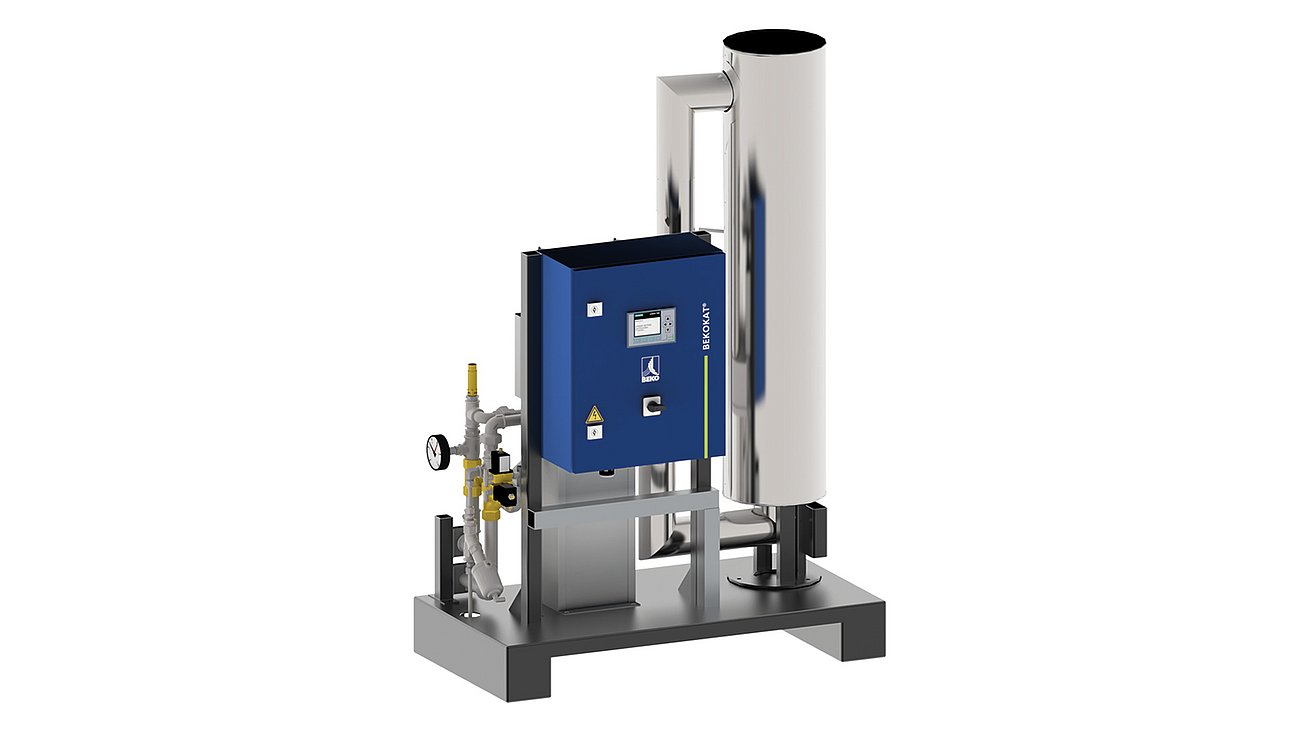

Long-Term Solutions

For those looking for the most substantial changes to their compressed air quality, Northwest Pump recommends finding solutions to remove both oil vapors and aerosols from the system entirely. This can be as simple as changing the compressor to an oil-free or oil-less machine. Alternatively, Beko offers BekoKat to elminate and Metpoint OCV to monitor oil vapor and aerosol present in your compressed air. The BekoKat is a catalytic converter that changes the hydrocarbons (oils) into CO2 and water. The Metpoint OCV offers real-time oil monitoring by sampling your compressed air every two minutes to give you peace of mind for your next air audit.

For those looking for the most substantial changes to their compressed air quality, Northwest Pump recommends finding solutions to remove both oil vapors and aerosols from the system entirely. This can be as simple as changing the compressor to an oil-free or oil-less machine. Alternatively, Beko offers BekoKat to elminate and Metpoint OCV to monitor oil vapor and aerosol present in your compressed air. The BekoKat is a catalytic converter that changes the hydrocarbons (oils) into CO2 and water. The Metpoint OCV offers real-time oil monitoring by sampling your compressed air every two minutes to give you peace of mind for your next air audit.

Next Steps

Northwest Pump is a leading distributor & service provider for compressor systems in the Pacific Northwest. Contact our compressor experts using the button on the left. For any service needs, including compressed air quality testing, please use the button on the right.

Jan 16, 2024 | Services

Whether working on a corporate fleet or providing maintenance to customers’ vehicles, having easy access to lubrication equipment in the shop increases overall efficiency. Northwest Pump has been a leading supplier of petroleum products since 1959. However, in the last few years, our Industrial Service Division has worked to provide custom-built lubrication system packages for customers. We offer lubrication solutions for any shop, fleet, or facility, with options for DEF to even window-washing fluid.

Our Expertise

Northwest Pump utilizes the Industrial Service technicians to install the lubrication systems. Our compressor technicians are already familiar with how to best install piping for optimal air pressure at point-of-use. The already-present compressors will provide the air needed to operate the air pumps controlling these systems. Another benefit for our current compressor service customers is our technicians’ familiarity with how the shop uses its air. Having an established relationship with the customer provides better insights and better outcomes for these lubrication systems. Our systems have an expected ‘lifespan’ of up to fifty years.

The Industrial Service Team has offered these system installation services since 2017, with over twenty-five projects completed since then. If service needs arise on our lubrication systems after installation, our Industrial service technicians will provide the required maintenance. The onsite installation team collaborates with the customers to build the best layout possible.

What to Expect During Lubrication System Installations

The lubrication systems we provide are custom-built to the customers’ needs, ranging from small portable systems to large systems spanning the interior and exterior of the shop. Our installation encompasses tanks to grease guns, using our high-quality hose reels, pumps, and piping. Metering and automation controls are also available for each nozzle for real-time analysis of how much lubrication is used per application.

Each fluid will have its own separate piping, nozzle, and tank systems. Our technicians have previously installed up to thirteen separate systems simultaneously. Depending on the spacing available within the shop, we will install as many fluids as the shop allows and or requires. Our team uses piping that we can bend onsite for faster installation times, or in case of any last-minute adjustments. The service technicians ensure the installed piping meets pressure and volume requirements. With pressure drops at every turn, we keep all piping straight with as few bends, curves, or fittings as possible. The result is a pristine, professional look in all the shops we work with.

Depending on the size of the shop’s interior or exterior, programming any additional automation equipment, and the amount of piping needed, our installation appointments can take as little as one day to complete or up to several weeks. Onsite technicians always inform customers of when potential downtimes may occur. However, they are able to adjust their schedule to minimize any downtime requirements, up to and including performing installations on the customer’s off-hours.

Next Steps

Learn more about our lubrication equipment installation capabilities by using the contact button below. Use the service button to contact our service team for repair, maintenance, or general service appointment needs.

Dec 11, 2023 | Industrial

While global supply chain strains were related to the COVID-19 pandemic, the semiconductor industry is still feeling the loss of production along with added pressure due to increased demand. The main cause of this shortage is that 75% of the world’s semiconductor supply has historically come from China and Taiwan. In the last few years, a global pandemic, trade difficulties, and natural disasters have impacted the region’s ability to produce the wafers, chips, and circuit boards that impact our everyday lives. As of August 2022, the US government has signed the CHIP and Science Act into law, providing funding for semiconductor manufacturers to begin production within the United States. Northwest Pump is committing to supplying critical equipment, such as acid transfer pumps, to semiconductor manufacturers on the West Coast.

CHIPS & Science Act

Since the CHIPS & Science Act was signed into law, the American government has allocated $39 billion in subsidies for US-based semiconductor manufacturers. These subsidies cover a wide range of financial assistance, including real estate costs, workforce expansion and training, childcare assistance, and more. Additionally, the CHIPS Act also provides a 25% investment tax credit for the costs of manufacturing equipment such as nitrogen generators for clean rooms, oil-free air compressors for wafer manufacturing, and acid transfer pumps for CMP processes. With these measures in place, the semiconductor sector in the US has seen tremendous growth in the past year.

How Northwest Pump is Impacting Manufacturing Efforts

Since 2021, Northwest Pump has committed to changing our stocking strategy when it comes to critical equipment for our customers. We have worked to reduce lead times by increasing on-hand stock from 25 to 40%, depending on the vendor, adding a new warehouse, and expanding our inventory and operations teams. As a result of these radical changes, we have reduced lead times from up to 20 weeks to as short as 2 weeks and, in some instances, even same-day shipping or pickup. Increasing on-hand stock has been especially true as Northwest Pump recently committed to being the master distributor for PSG, a Dover Company’s European brands: Almatec, Abaque, and Mouvex.

AODD Pumps for Semiconductor Manufacturing

Air-operated double-diaphragm pumps offer a unique solution when compared to other types of positive displacement pumps, and this is no different for the semiconductor industry. For one, an AODD pump does not need an electrical power source. These pumps operate automatically once they are connected to a source of compressed air. This means an AODD pump can be just as effective submerged in fluid as it is outside of the container. AODD pumps offer shear sensitivity, working gently with or without solid particles or even slurries. Another benefit is that they are self-priming and can be deadhead without causing damage to the pump.

The durability and gentle fluid-handling qualities make AODD pumps a common choice for chemical transfer applications. They can operate in wide ranges for both temperature and pressure. If the compressed air exceeds its pressure capabilities, the pump simply spits out the air and resumes operation once again. These qualities also carry over to the semiconductor industry, where high-purity chemicals assist with CMP processes. Later, these pumps can assist in moving these chemicals after they mix with waste process water or even waste gases from clean rooms.

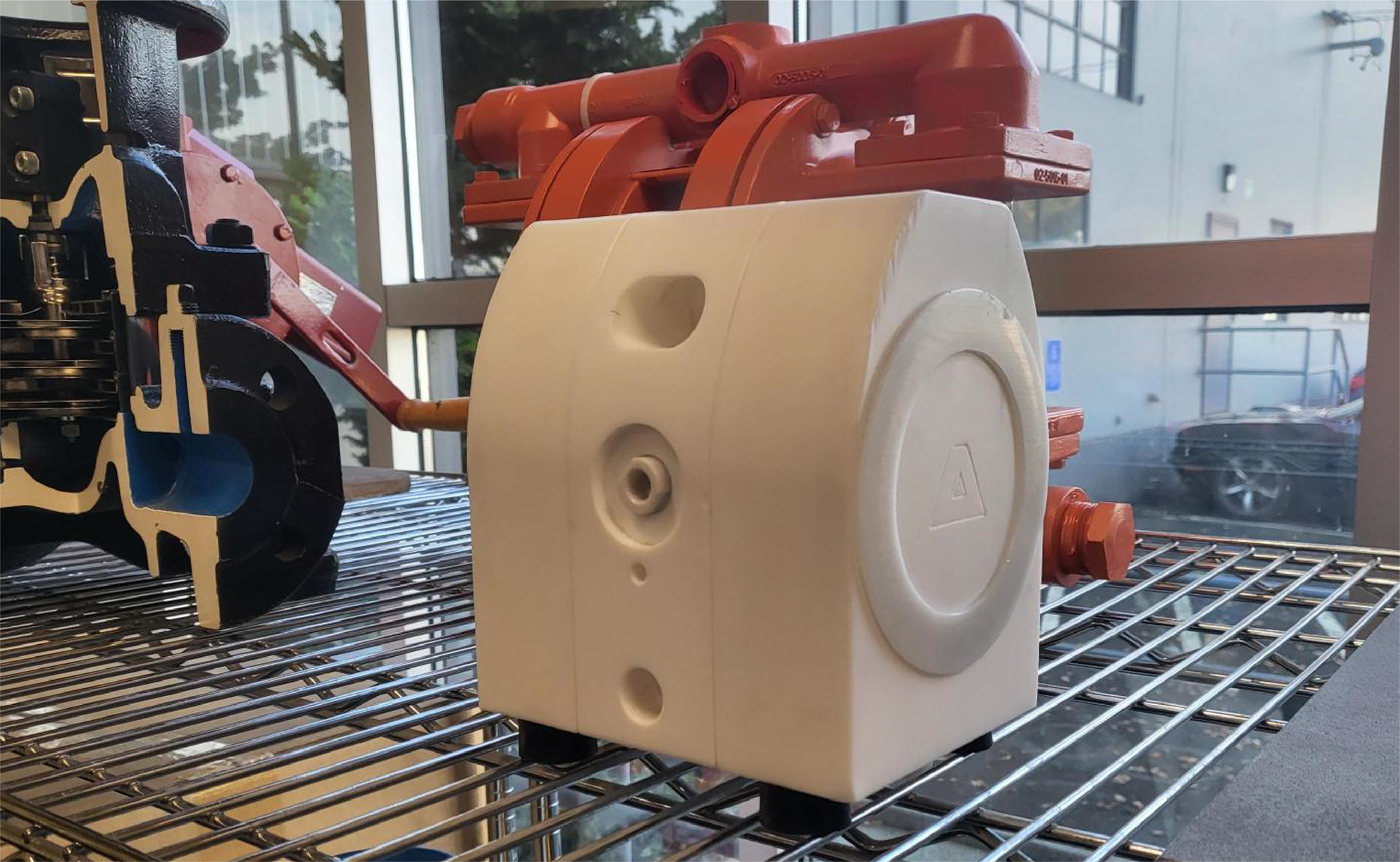

The Almatec Advantage

Almatec is a German-manufactured brand specializing in AODD pumps for high-purity chemical and acid transfer. What sets this brand apart is the construction; it machines its pumps out of solid blocks of PTFE, PE, or corrosive-resistant metals. Almatec’s plastic pumps have no metal in the wetted housing, which could be at risk in corrosive pumping applications. The E series pumps from Almatec can work in operating conditions up to 248°F, while the semiconductor specific FUTUR series can work with chemicals at near 400°F. Additionally, Almatec assembles its specialty FUTUR series pumps in cleanrooms to prevent unnecessary contamination from dust or dirt.

Next Steps

Northwest Pump is the master distributor for Almatec on the West Coast and in the Midwest, ranging from New Mexico to North Dakota. To find your local distributor for Almatec Pumps, see our distributor list below. For more information on how Almatec’s acid transfer pumps can help your semiconductor manufacturing processes, contact us using the button below. Use the ‘Request Service’ button below for service needs on your Almatec or AODD pumps.

Distributor

|

Location

|

Website

|

| Northwest Pump |

Portland, Seattle, Spokane, Billings Branches |

Contact NW Pump – The Leader in Petroleum and Industrial Equipment |

| Central States Group |

8720 S 137th Circle, Omaha, NE 68138 |

Central States Group |

| Denver Industrial Pumps |

15165 W 44th Ave, Golden, CO 80403 |

Denver Industrial Pumps |

| Folsom Associates |

516 W Stockman Way, Ogden, UT 84401 |

Folsom Associates |

| Phoenix Pumps |

5100 S 36th St, Phoenix, AZ 85040 |

Phoenix Pumps |

| DXP Enterprises |

3409 NE 65th St, #101, Vancouver, WA 98661 |

DXP Enterprises |

Nov 8, 2023 | Petroleum

What is NEVI?

The National Electric Vehicle Infrastructure (NEVI) is a program managed by the Federal Highway Administration (FHWA). NEVI aims to fund a resilient, equitable, and accessible national network of Level 3 EV fast charging stations along the nation’s highways.

Each state participated in helping map “Alternative Fuel Corridors” that string a chain of EV charging stations spaced no more than 50 miles apart in pathways that create an interconnected network. This will allow EV owners to travel cross-country without having the fear of running out of power.

How Northwest Pump Can Help You

At Northwest Pump, we can provide all the products you need to attract new and existing charging clients that will put your site’s location/s on the map. Once you have applied and been approved, we can start the process of getting you the right products. Here is our product lineup:

Requirements To Meet NEVI Funding

NEVI requires that states meet strict specifications in their EV plans and networks in order to qualify for the funds. These requirements were designed to provide convenient charging for EV drivers who need fast charging locally or while on a trip. To be eligible for funding of up to 80% of project costs, locations must:

- Be within 1 mile of established alternative fuel corridors (AFCS).

- Accommodate the power requirements for DC solutions.

- Charge four vehicles at 150 kW at the same time.

- Cover remaining total project costs.

Special Financing Options Provided by Patriot Capital

Our special program & partnership with Patriot Capital lets us offer 3 options that are available for NEVI program transactions. These programs provide between 20-100% financing options with varying terms.

Next steps:

Once you are qualified for a NEVI site, use the “Contact Us” button to get in touch with your Northwest Pump sales rep. If you want to learn more information regarding NEVI in other states, you can click the “More Information” button.

Nov 6, 2023 | Industrial

Corrosives can hurt more than just your seawater pumps. Whether the pumped fluid is seawater or sulfuric acid, once it encounters the wrong material, it will continue to corrode your pump and any other equipment it reaches afterward. While some materials fare better when working with corrosives, it is not always practical to change everything to a resistant material. Industrial and marine coating products help protect your equipment from harmful conditions, including aggressive weather conditions.

What is a marine coating?

An industrial coating is made of layers of protective, waterproof material, such as epoxy resin, which protect against untimely damage. Industrial coating can be used on metal equipment or on concrete floors or walls. Depending on the application style, coatings come in liquid, aerosol, powder, paste, and film.

A marine coating will differ from an industrial coating in two ways. Most marine coatings will be best suited for coating metal surfaces. Additionally, the protections it offers are specific to sea or freshwater needs. When searching for the right marine coating, the key features to look for are:

- High corrosion resistance

- High abrasion resistance

- Low volatile organic chemical content (also referred to as VOC)

- Operating temperatures best-suited for local environment

Another factor in finding the right marine coating is the pot life and curing time. Because of the innate adhesive design of industrial coatings, understanding how long the material will remain in a liquid state (pot life) is another important factor in knowing when to replace excess containers. Curing time will vary depending on the environment, including ambient temperatures and humidity, and will impact how long it takes for a coating to go from a ‘tack-free’ state to ‘full chemical resistance’. Keep in mind that the faster the coating dries, the shorter it will take before it hardens after opening.

Where can marine coatings be applied?

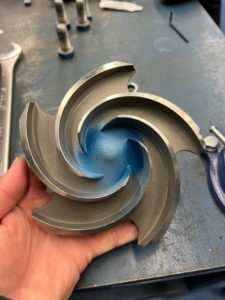

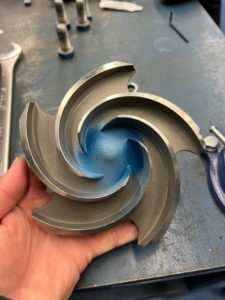

Marine and industrial coatings can protect both the exterior casing and sometimes even the wetted housing of your pump. Coating works on impellers, blades, bearings, valves, or any place in a pump that can encounter corrosive fluid. Beyond the pump, coatings prevent slip hazards before they occur, as well as reduce corrosion damage. Tanks, pipes, bins, silos, and hoppers can also benefit from the use of marine or industrial coatings.

Chesterton ARC Industrial Coating

A.W. Chesterton specifically created the ARC 858 with marine-duty applications in mind. This marine coating uses a reinforced abrasion-control epoxy compound to protect metals against damage caused by seawater and other harsh chemicals. The design of ARC coatings reduces downtime, with only one coat needed. With high adhesive strength, ARC 858 protects against corrosion above and even below the film layer. ARC 858 works with new and current equipment to ensure a longer lifespan, and requires minimal downtime for the application process. Check out this case study where the use of ARC 858 helped to increase the lifespan of a seawater pump 18 years after the initial application, 3 times longer than the original goal.

For ship deck protection, Chesterton offers ARC 855, which uses a ceramic-reinforced epoxy coating to protect the material beneath from corroding and prevent slip hazards when applied to high-foot-traffic areas. Not only did ARC 855 reduce slipping incidents by 80% in one case study, but it also saved over $20,000 by reducing the amount of coating applied.

Next Steps

Northwest Pump offers ARC 858 and other equipment solutions for the marine industry. Use the buttons below to contact us or request help from our service team.

For those looking for the most substantial changes to their compressed air quality, Northwest Pump recommends finding solutions to remove both oil vapors and aerosols from the system entirely. This can be as simple as changing the compressor to an

For those looking for the most substantial changes to their compressed air quality, Northwest Pump recommends finding solutions to remove both oil vapors and aerosols from the system entirely. This can be as simple as changing the compressor to an