One common pain point for manufacturing plants is repeated pump failure in and around washdown applications. Facilities risk losing tens of thousands of dollars when using equipment not meant for washdown. Whether preventing a failure before it happens or troubleshooting existing washdown equipment, our team of pump experts, engineers, and service technicians can help with washdown needs in your facility.

What kind of facilities need washdown equipment?

Washdown processes are not necessary for every industry. The three industries that typically require washdowns are food & beverage, marine, and those working with heavy-duty chemicals. Without these features, corrosive chemicals or bacteria can damage washdown equipment. This is especially true for marine applications with seawater and bacteria ever-present.

What kinds of pumps are best for washdown applications?

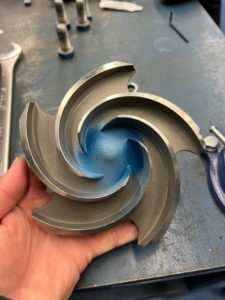

Because of the specific industry-specific needs for washdown applications, pumps designated for washdowns need stainless steel for the wetted housing or use a sanitary-grade industrial coating. Both prevent untimely wear and tear on the pump itself.

The two most common styles of pumps for washdown applications are centrifugal and air-operated double-diaphragm (AODD). Centrifugal pumps are some of the most common on the market because of their pressure-boosting capabilities and the tendency towards higher flow applications. AODD pumps, on the other hand, have a significant advantage in washdown applications: the motorless design prevents the leading cause of pump failure during washdowns.

What is a motor washdown rating & how important is it?

The biggest concern when working in washdown applications is not the style of a pump but the motor. Washdown-rated motors protect the fragile electrical components against the large volumes of water required for these types of applications. A standard motor is prone to rust or water leakage into the electrical components that enable the pump to run, making it unsuitable for washdowns. Additionally, long-coupled pumps will require a washdown-rated coupling guard to protect the coupling element from water damage.

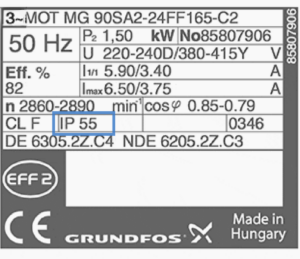

The International Electrotechnical Commission (IEC) designed an Ingress Protection, or IP, rating system to specify how a motor’s enclosure protects from outside contaminants. Manufacturers display the IP ratings on the motor tag and in the motor’s manual. This rating uses two numbers, each representing how it blocks solids or liquids. The first digit will be a number from 0-6, and this scale represents how this enclosure will prevent solid objects from reaching the internal mechanisms. The second digit scales 0-9 to indicate how the enclosure prevents liquids from interacting with the electrical components. Motors with no protection against dust or water would have an IP00 rating. Conversely, a motor with an IP69 rating indicates protection from dust and water resistance even while submerged in shallow water. Typical washdown applications have IP ratings ranging from 55-69, depending on the spray pressure.

Do I need another pump to boost pressure for washdown?

While having pressure booster pumps or pump skids in addition to the washdown pumps is not uncommon, not all washdown applications require increased pressure. Facilities with multiple washdown systems in place or far away from their local water utility distribution system will likely benefit from installing a booster system in addition to their existing washdown equipment.

Our Washdown Equipment Vendors

Pump Vendors

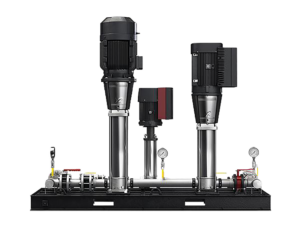

Grundfos

While pumps are not the pain point in washdown needs, Grundfos sets itself apart for washdown equipment with the Hydro HP pump system. The Hydro HP is not one single pump, but a complete assembly of in-house manufactured CR/CRN pumps, washdown-rated motors with an equivalent IP 66 rating, and automation & real-time monitoring accessories applied to a baseplate ready to connect to your existing pump system.

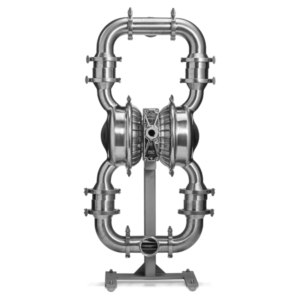

Wilden

These industry-renowned AODD pumps take the hassle out of maintenance. Since AODD pumps do not require a motor, they stand out as an option for washdown applications. Wilden builds its AODD pumps with as few parts as possible to simplify assembly & disassembly of the pump. The Saniflo series from Wilden features stainless steel construction to prevent bacterial growth during periods of non-use, maintaining the washdown-standard design.

Motor Vendors

WEG

WEG offers washdown-rated motors with IP56 or IP69 ratings to fit your needs. This vendor manufactures durable equipment with a patented three-stage sealing system to ensure a watertight fit. To validate this claim, WEG offers a substantial motor warranty with protection for up to twelve months from the installation date or twenty-four months from the assembly date listed on the motor tag.

Baldor

Baldor offers motors with IP ratings up to IP69, including a specific Food-Grade motor to keep with sanitation standards set by the FDA. These motors also offer a ‘footless’ CIP-in-mind design to reduce the surface area for cleaning.

Custom-Built Washdown Pump Skids

Northwest Pump

For those looking for precision control for their washdown needs, Northwest Pump offers custom fabrication services through our Industrial Service Division to create the washdown pump skid you need. Whether you supply the plans or let our engineers lend a hand, our service technicians work with you to build to your specifications.

Next Steps

Are you in search of the perfect washdown solutions for your facility? Look no further! We can provide the most suitable washdown solutions to meet or even exceed your requirements. Trust us to deliver a top-notch solution that leaves your facility sparkling. Contact us below to get started.