May 10, 2022 | Industrial, Services

Summer is just around the corner, and with the change in season, now is the perfect time to check your entire facility and prevent emergencies before they happen. Here are ten ways to check the health of your pumps and air compressors and a pair of seasonal facility maintenance checklist printouts below to keep on hand.

Compressor Checklist

□ Change your oil

Whether a compressor is oil-flooded or oil-free , the start of a new season is the perfect time to refresh the oil on a compressor. Keep in mind, that some brands need specific lubricants. For example, Sullair compressors need genuine Sullube to keep within warranty. Additionally, why not conduct an oil sampling? This also protects the diamond warranty, and lets you know about the health of your compressor.

, the start of a new season is the perfect time to refresh the oil on a compressor. Keep in mind, that some brands need specific lubricants. For example, Sullair compressors need genuine Sullube to keep within warranty. Additionally, why not conduct an oil sampling? This also protects the diamond warranty, and lets you know about the health of your compressor.

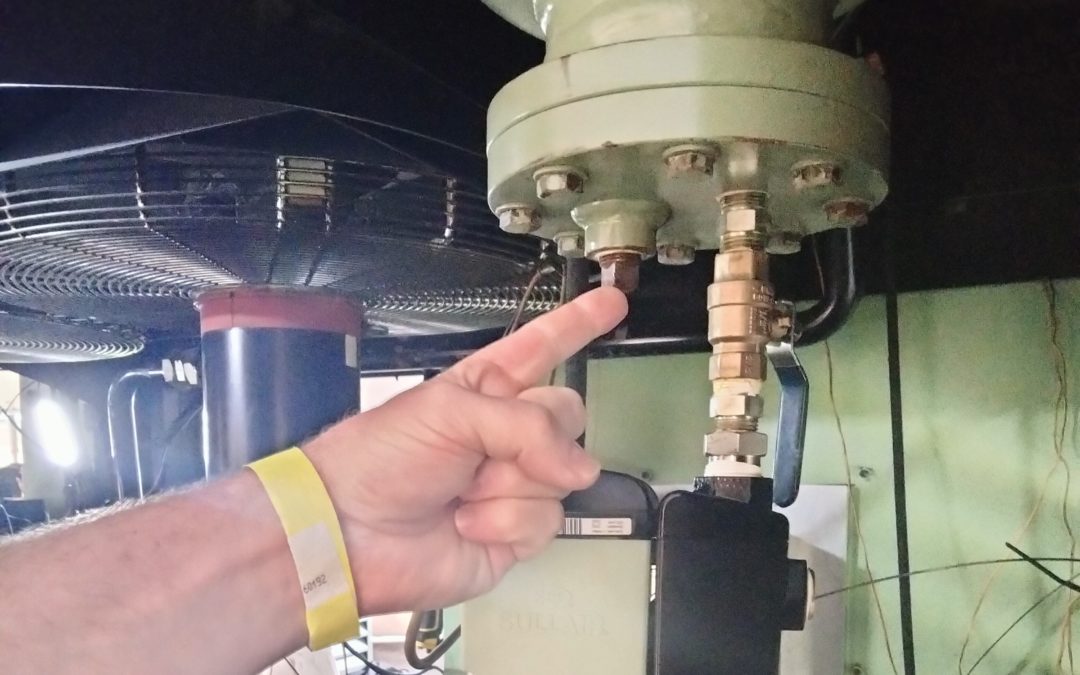

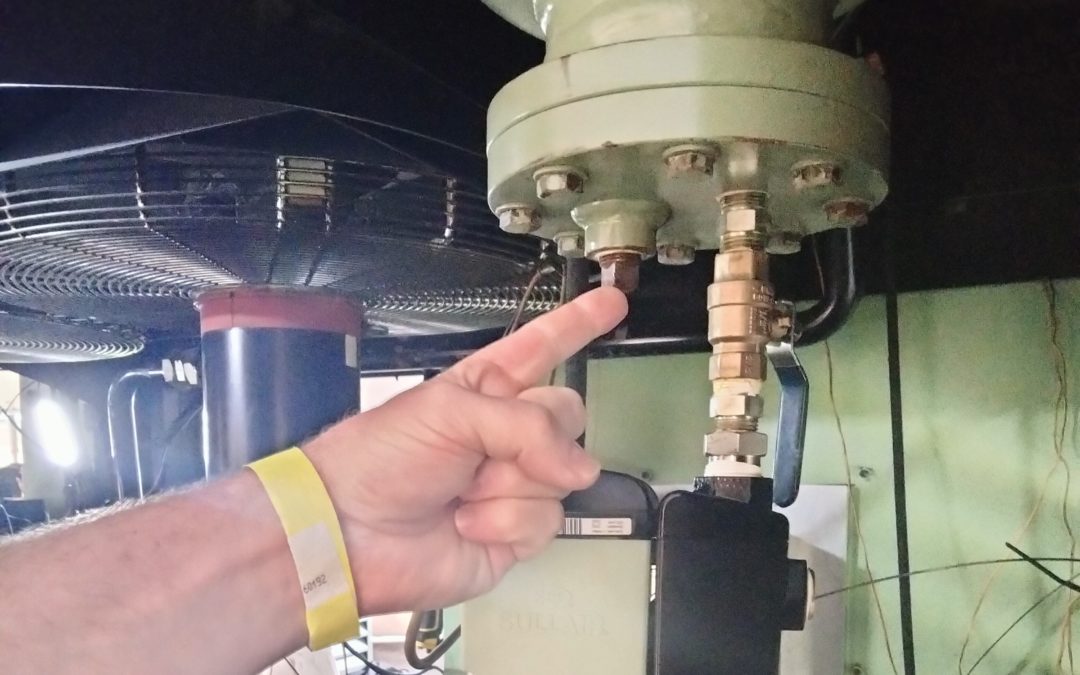

□ Check your oil cooler & aftercooler

One of the many uses of oil in the compressor is to reduce the heat within the machine. This process protects the machinery from unnecessary damage, and why checking the oil cooler & aftercooler should be on your list.

□ Check your package air inlet filters

The easiest way to check if the package air inlet filter needs a replacement is by hovering your hand over the top of the compressor. If you feel a breeze, then your inlet filter is working just fine. If there is a weak breeze or none at all, it’s time for the filter to be cleaned or replaced. This check is especially helpful for compressors that are in environments with more dust or other particles in the air that can clog up filters.

air inlet filter needs a replacement is by hovering your hand over the top of the compressor. If you feel a breeze, then your inlet filter is working just fine. If there is a weak breeze or none at all, it’s time for the filter to be cleaned or replaced. This check is especially helpful for compressors that are in environments with more dust or other particles in the air that can clog up filters.

□ Check the make-up air

In a similar vein, checking the room a compressor is in is also important. The three points to consider are: making sure that the air surrounding the air compressor (make-up air) is free of particles and other contaminants, making sure that make-up air is adequate, and making sure that the temperature in the room can withstand compressed air that is 15°F higher than the ambient temperature.

In a similar vein, checking the room a compressor is in is also important. The three points to consider are: making sure that the air surrounding the air compressor (make-up air) is free of particles and other contaminants, making sure that make-up air is adequate, and making sure that the temperature in the room can withstand compressed air that is 15°F higher than the ambient temperature.

If you don’t have a manometer to check the adequacy of your make-up air, one easy test is to test the compressor room door. Is it difficult to open when you open the door, or does it try to slam shut when you let go? If so, you should consider consulting one of our specialists to help you redesign your make-up air to the room.

□ For Variable Speed Drives Only: Check your cooling fan & filter

One of the benefits of variable speed drives is that if the machinery is not used continuously, the compressor will be far more efficient in stopping and starting. However, this means that the cooling fan may wear down easier in the shut-off process. Now is the perfect time to make sure your cooling fan & the filter to it can beat the summer heat.

Pump Checklist

□ Check Oil/lubrication on pumps

When conducting any kind of seasonal equipment maintenance, checking oil is a vital first step. For a pump to run properly, the rotating or moving parts must be able to move freely, and the stationary parts must stay where they need to be. So, making sure that those moving parts are properly lubricated is the first thing to check on your pump.

□ Lubricate Bearings

Similarly, making sure that the joints & bearings on your pump are lubricated is also very important. However, it is even more important to make sure that your bearings are not over lubricated, as this also damages your pump. Consult your pump’s manual or user guide to know how much lubrication is needed for your bearings.

For facilities that do not want to spend the time to check the user manual for every pump and then lubricate every bearing, A.W. Chesterton offers the Lubri-cup as the perfect solution. This device automatically dispenses the preprogrammed amount of lubrication to the pump. One Lubri-cup can reduce a facilities manager’s workload by two days, which means your team can spend more time on other tasks than just lubricating pumps.

For facilities that do not want to spend the time to check the user manual for every pump and then lubricate every bearing, A.W. Chesterton offers the Lubri-cup as the perfect solution. This device automatically dispenses the preprogrammed amount of lubrication to the pump. One Lubri-cup can reduce a facilities manager’s workload by two days, which means your team can spend more time on other tasks than just lubricating pumps.

□ Check Mechanical Seals and Packing (if applicable)

The more leaks a pump has, the less efficient it will be. One of the easiest places for leaks to occur is in the seals. So, if your pump has mechanical seals to prevent leaks, check those fairly often. If there is a puddle underneath a seal, you need a new seal. The same also goes for pump packing as well.

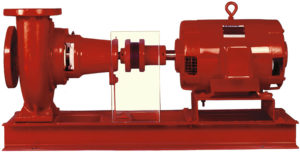

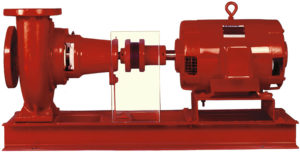

□ Check the Coupling Element

Image from Pumps & Systems

If your pump has a coupling element, it will be located between the motor & pump (see image to the right). If your motor & pump are not properly aligned, you will wear out not just the coupling element but the motor & pump as well. So, if you look at your pump and there is shredded material below your coupling element, call your pump service provider immediately.

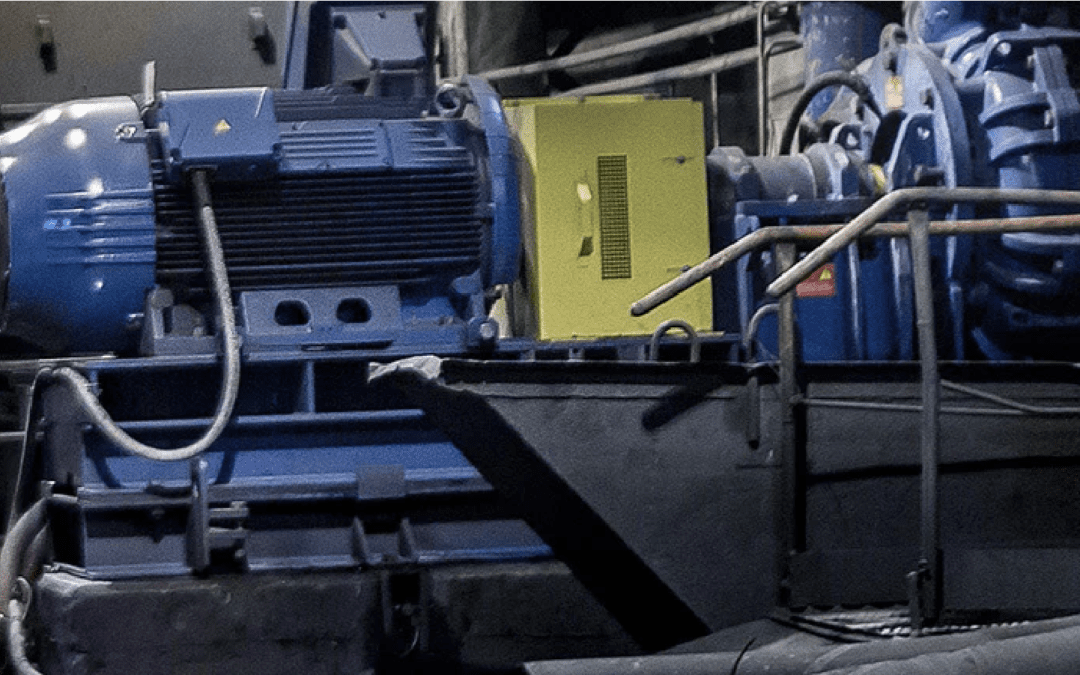

□ Feel your pump

Our pump technicians also recommend checking your pumps at startup by placing one hand on the motor and one hand on the pump where it is safe to do so. When your pump turns on, you should feel smooth vibration. If you feel a lot of vibration or your pump is louder than usual, that means it could be experiencing cavitation or air pockets. These air pockets damage the interior of the pump, which can then lead to replacing a pump earlier than expected.

Next Steps

Download an air compressor-specific seasonal facility maintenance checklist by clicking here. Download the pump checklist by clicking here. If you need help completing this checklist, why not consider Northwest Pump’s Rotating Equipment Service Agreements. Email our service team at service@nwpump.com or call us at 1-866-577-2755 to have a customized service plan of your own.

Apr 25, 2022 | Services

Are you looking for simplicity, control, and flexibility in your POS system? Don’t look any further because the Gilbarco Passport Point-of-Sale System is just that. Investing in Passport today means investing in the POS technology of tomorrow.

With Passports touchscreen and intuitive design, Gilbarco will have your business’s employees trained within 20 minutes or less. Passport’s unmatched simplicity allows you to focus on your strategy, not your technology. Extensions within the Passport ecosystem allow you to serve and reach your customers across your entire site and entire network site.

Manage Smart. Stay Secure.

By being first to market with an outdoor EMV solution, Gilbarco has honed the EMV transition process with special features like functionality that ensures no bank card is left behind by consumers.

Passport’s easy integration with third-party systems and powerful reporting and tracking tools give you everything you need to run and manage a cutting-edge fuel retailing system. The Method of Payment Report calculates credit and debit transactions for fuel, merchandise, and car wash sales to reduce card processing fees.

Additionally, Passport provides sophisticated alerts and safeguards that help your employees perform at their best and secure your investment. It all adds up to tighter security, fewer surprises, and better results for you, your employees, and your customers.

More Partners. More Possibilities.

Gilbarco’s POS Passport has more than 120-certified partners, allowing you significant flexibility to most effectively meet your evolving needs.

Here are the partners that cover all your needs: Back Office Systems, Broadband/WAN Networking Solutions, Car Wash Controller, Electronic Loyalty Programs, Integrated Loyalty Programs, Mobile Payment Processing Networks, Proprietary Fleet / Auxiliary Network Security Camera, and Tank Gauges.

Third Party Developer Support

This portal is specifically designed to support third-party companies interested in interfacing. Gilbarco Passport point-of-sale systems and/or developing applications for use on the new Encore Experience forecourt applications solution.

Next steps

If you are interested in Gilbarco’s POS System, we currently have stock in our branches and can ship your product out today!

- MOC Pricing (call for bulk discounts)

- UPS included

Contact our POS contact, Tim!

Apr 11, 2022 | Industrial, Services

When equipment fails, no feeling can be better than knowing that there is a warranty to protect from unnecessary costs of repairs or replacements. Many of our vendors offer warranties; however, Sullair offers a superior compressor warranty in the industry to prove their products’ quality. Here is what you need to know about Sullair’s Diamond Warranty.

What does this compressor warranty cover?

The majority of Sullair’s compressors include  the Diamond Warranty*. It covers most Sullair compressor units with a discharge pressure of 150 PSIG or less. The warranty covers all major components for new air compressors, including 10 years on the air end plus 5 years on the motor and other components such as the air/fluid receiver, oil cooler, and aftercooler. The extent of warranty coverage shows how confident Sullair is in the longevity of its products.

the Diamond Warranty*. It covers most Sullair compressor units with a discharge pressure of 150 PSIG or less. The warranty covers all major components for new air compressors, including 10 years on the air end plus 5 years on the motor and other components such as the air/fluid receiver, oil cooler, and aftercooler. The extent of warranty coverage shows how confident Sullair is in the longevity of its products.

* Sullair’s ShopTek Series compressors are no longer eligible for the diamond warranty as of May of 2023, the emerald warranty comes as standard for this series.

How do I maintain this warranty?

Every warranty has terms and conditions to ensure that equipment is kept to standards before repairs, and Sullair’s Diamond & Emerald compressor warranties are no different. To be eligible for either, facilities will need to follow five guidelines, which are:

- An authorized Sullair Distributor must do startup & serving and complete the warranty documentation.

- All compressors built after January 1, 2014, must participate in Sullair’s oil sampling program. Participating facilities must take samples every 2000 hours (or twice per year, whichever occurs first). Missed intervals or two bad tests void the warranty.

- Purchaser(s) must use genuine Sullube® lubricant.

- Purchaser(s) must maintain the machine(s) at Sullair’s recommended intervals & requirements.

- The compressor covered must use genuine Sullair parts.

Next Steps

Ready to protect your investment? Tell us about your equipment here, email us at sales@nwpump.com, or call 1-800-452-PUMP for next steps. Need help with oil sampling and maintenance? Email service@nwpump.com or call 1-866-577-2755 for more information.

Feb 1, 2022 | Industrial, Services

Machines, much like people, require routine check-ups to stay healthy and run as expected. Remembering when to schedule regular maintenance appointments can be difficult with a busy schedule and forgetting will almost certainly lead to an emergency. Some maintenance companies offer service plans. However, the contracts offered generally mean that a business can only use one company for repairs. Furthermore, the schedule does not always align with the machinery’s needs. At Northwest Pump, we offer rotating equipment service agreements, focused on your equipment and your schedule.

Why an agreement?

While contracts & agreements are very similar, a few differences will determine which option is better. A contract is legally binding, and cannot be easily undone without paying fees, advanced notice, or other similar conditions. An agreement, while still binding, is more informal. Northwest Pump’s agreement only requires a 30-day notice of cancellation and is non-exclusive. Our agreement is also considered flexible, meaning that we tend to your machines on a quarterly, semi-quarterly, or annual basis depending on your needs.

How Our Rotating Equipmentment Service Works

Instead of a facility needing to schedule service appointments, our team will keep track of it- that means one less thing to worry about. Our team will call you to schedule an appointment in advance, and we will coordinate from there. The agreements operate on an annual, semi-annual, or quarterly basis, depending on your needs. Northwest Pump has two rotating equipment service agreement options, one for compressors and one for pumps.

Pump Services

Our pump station service agreement includes removing all fluids & debris from the pump (as needed), pressure washing the pump station, a full test cycle on all pumps, checking amps & pumps, verifying pumps are operating to manufacturer’s standards, cleaning floats, inspecting for broken parts or other obvious safety issues, inspecting alarm & performing test calls, & recommendations for future service needed.

Compressor Services

Northwest Pump offers service intervals every 2,000 hours or three months, whichever is first, or at other mutually agreed upon and set intervals. We also provide an annual service interval every 4,000 to 8,000 hours depending on lubricants in your compressor, or once a year, whichever is first. These service appointments include a complete visual inspection, an oil level check, inspection of air filter & change (if appropriate), oil filter replacements (if applicable), check separators’ differential pressures, checking oil return lines & valves, checking operating temperatures & cooling systems, control inspection, air discharge inspection & adjustment (if appropriate), an inspection of belt tension, electrical system check with amp draws & voltage, air dryer & filtration inspection, and a checklist of all components inspected and or serviced.

Northwest Pump offers service intervals every 2,000 hours or three months, whichever is first, or at other mutually agreed upon and set intervals. We also provide an annual service interval every 4,000 to 8,000 hours depending on lubricants in your compressor, or once a year, whichever is first. These service appointments include a complete visual inspection, an oil level check, inspection of air filter & change (if appropriate), oil filter replacements (if applicable), check separators’ differential pressures, checking oil return lines & valves, checking operating temperatures & cooling systems, control inspection, air discharge inspection & adjustment (if appropriate), an inspection of belt tension, electrical system check with amp draws & voltage, air dryer & filtration inspection, and a checklist of all components inspected and or serviced.

Next Steps

To hear more about our rotating equipment service agreements, email us at service@nwpump.com, or call us at 1-866-577-2755. Want to send your equipment in for repairs? Find out what our shop can do here, and request service here.

Jan 12, 2022 | General, Industrial, Services

Knowing what kind of Slurry pump to use can make an enormous difference for any facility in the Aggregate Industry. The wrong type of pump will lead to inefficiency, premature pump breakdowns, and inevitably spending more to replace it. One factor that will affect which kind of pump, is whether the inside is metal or has a rubber lining. This choice can change how much money you spend on said pump and its replacement parts. Here are a few things to take into consideration when deciding what kind of slurry pump to use.

Metal Pumps

The aggregate industry prizes metal pumps because of their tough nature. While all slurry pumps receive wear & tear, certain metals will withstand damage better than others, such as plastic or urethane. However, this property also means the initial cost will be higher than the rubber-lined pumps. Servicing periods, though more expensive, will also be more sporadic to offset the costs. Another consideration for using steel piping is the contents of the slurry. If a slurry contains rocks that are 3/8″ or larger, then a rubber-lined pump might wear out too quickly. Knowing what makes up your slurry solution and how the pump’s materials react are crucial for making your pumping choice.

Rubber-Lined Pumps

Rubber-lined slurry pumps will cost less than their metal counterparts. Because the insides of this pump are rubber instead of metal, this pump will require replacing the interior parts much sooner than a metal pump. However, because of the smaller intervals, the cost of these replacement parts is significantly smaller than replacing an entire pump down the road. Recent technology has allowed the rubber-lined pumps to last longer than previous versions, meaning the gap in lifespans between metal and rubber-lined pumps are shorter than ever. Additionally, one key piece of information to determine if a rubber-lined pump will work for your system, is knowing exactly what is pumping through it. A wrong combination of rubber with the sand within the slurry can cause a pump to wear out prematurely.

Our Brands for your Slurry Solutions

Northwest Pump has several options to optimize any aggregate facility. Metso:Outotec not only has the pumps for the mining industry, but complete slurry hose systems, which include: rubber hoses, rubber-lined piping, bends, couplings, and gaskets. Metso offers their slurry pumps with either high chrome or rubber-lining that is designed explicitly for the industry. This brand also offers the latest filtration system technology, including sustainable practices that have reduced excessive water usage at facilities. Metso specifically, designs their Orion series pumps for heavy-duty mining applications with special bearings to protect the pump & to continue use even as it wears down.

Atlas Copco

For a more mobile solution, Atlas Copco offers portable pumps that are easily transferable. These diesel pumps can pump up to 8,600 gallons per minute. Portable pumps are self-priming, so they do not need lubrication like standard pumps.

Next Steps

You can contact us for your next slurry pumping solution here, email us at sales@nwpump.com, or call 1-800-452-PUMP.

You can contact us for your next slurry pumping solution here, email us at sales@nwpump.com, or call 1-800-452-PUMP.

Need your mining equipment serviced? Contact our service team here, email service@nwpump.com, or call 1-866-577-2755!

Dec 2, 2021 | General, Industrial, Services

What are ANSI Pumps, and Why Should You Care?

Beyond the type of pump, there are several ways to classify pumps further. One such specification is whether a centrifugal pump follows ANSI specifications (also referred to as ASME B73.1). ANSI pumps refer to a specific set of standards created back in the 1970s. However, the B73 committee updated the regulations as recently as 2016. These standards mean that these pumps are interchangeable and optimized for easier maintenance and reliability in mind. A facility with ANSI pumps does not have to worry about adjusting the motor, the location of the pumping system, or the coupling mechanisms- even if a facility changes manufacturers.

The ANSI pumps are separated into three groups depending on size. There are currently over 27 size variations available depending on one’s needs. Whether a facility chooses the tiniest specification or the largest, all ANSI pumps are rated for 300psig at 300°F or 149°C. Additionally, while these standards originated for oil & gas refining, they have a broad scope for usage in food production, textiles, chemical processing, and pulp & paper industries, to name a few. However, despite their ability to contain some solids (depending on impeller design), these pumps will not work for thick, viscous liquids. Another benefit to ANSI specifications is that these pumps will be more widely available because of their abilities. Not only does this make ANSI pumps cost less, but it also makes finding parts for repairs that much easier.

When it comes to ANSI pumps, Northwest Pump prefers utilizing PSG Griswold’s expertise. Griswold ensures their quality standards with not only certified highest-quality parts but also a five-year warranty.

What other options are available?

While these pumps are certainly beneficial for some situations, they are not ideal for every pumping situation. Instead of choosing from the above ANSI specifications, a facility might desire a more robust approach. One such option may be Blackmer Centrifugal. Formerly System One, Blackmer makes pumps with durability in mind, with their average pumps rated for up 650°F/343°C and beyond. Additionally, the design of Blackmer Centrifugal means that the seals & bearings are better protected, ensuring a longer life for pumps that see heavier duty work than others. These pumps are optimal for mining operations, water & wastewater handling, and chemical processes.

While these pumps are certainly beneficial for some situations, they are not ideal for every pumping situation. Instead of choosing from the above ANSI specifications, a facility might desire a more robust approach. One such option may be Blackmer Centrifugal. Formerly System One, Blackmer makes pumps with durability in mind, with their average pumps rated for up 650°F/343°C and beyond. Additionally, the design of Blackmer Centrifugal means that the seals & bearings are better protected, ensuring a longer life for pumps that see heavier duty work than others. These pumps are optimal for mining operations, water & wastewater handling, and chemical processes.

What Pump is Right for You?

Whether it is the main producer or a supporting feature, a facility needs an optimized pump for its needs. So, knowing how a pump can serve a need is essential. When choosing a pump, anyone should know how the specifications impact the safety, the maintenance requirements, and the fluid contained inside the pump. Between Blackmer & Griswold, here is how the two stack up. When it comes to safety, both will protect employees and the facility, however with high temperatures or harsher applications, Blackmer Centrifugal will probably rank higher. Maintenance for Griswold will be far less invasive than Blackmer. While the fluid will depend on the needs of the facility when it comes to costs, both will be worth it, Griswold will be more accessible due to their product line.

Want to see if an ANSI pump is right for you? Reach out and let’s start the conversation at sales@nwpump.com, or call us at 1-800-452-PUMP. Need maintenance on your ANSI pump? Call us at 1-866-577-2755 to schedule an appointment or make a request here.

, the start of a new season is the perfect time to refresh the oil on a compressor. Keep in mind, that some brands need specific lubricants. For example, Sullair compressors need genuine Sullube to keep within warranty. Additionally, why not conduct an oil sampling? This also protects the diamond warranty, and lets you know about the health of your compressor.

, the start of a new season is the perfect time to refresh the oil on a compressor. Keep in mind, that some brands need specific lubricants. For example, Sullair compressors need genuine Sullube to keep within warranty. Additionally, why not conduct an oil sampling? This also protects the diamond warranty, and lets you know about the health of your compressor. air inlet filter needs a replacement is by hovering your hand over the top of the compressor. If you feel a breeze, then your inlet filter is working just fine. If there is a weak breeze or none at all, it’s time for the filter to be cleaned or replaced. This check is especially helpful for compressors that are in environments with more dust or other particles in the air that can clog up filters.

air inlet filter needs a replacement is by hovering your hand over the top of the compressor. If you feel a breeze, then your inlet filter is working just fine. If there is a weak breeze or none at all, it’s time for the filter to be cleaned or replaced. This check is especially helpful for compressors that are in environments with more dust or other particles in the air that can clog up filters. In a similar vein, checking the room a compressor is in is also important. The three points to consider are: making sure that the air surrounding the air compressor (make-up air) is free of particles and other contaminants, making sure that make-up air is adequate, and making sure that the temperature in the room can withstand compressed air that is 15°F higher than the ambient temperature.

In a similar vein, checking the room a compressor is in is also important. The three points to consider are: making sure that the air surrounding the air compressor (make-up air) is free of particles and other contaminants, making sure that make-up air is adequate, and making sure that the temperature in the room can withstand compressed air that is 15°F higher than the ambient temperature. For facilities that do not want to spend the time to check the user manual for every pump and then lubricate every bearing, A.W. Chesterton offers the Lubri-cup as the perfect solution. This device automatically dispenses the preprogrammed amount of lubrication to the pump. One Lubri-cup can reduce a facilities manager’s workload by two days, which means your team can spend more time on other tasks than just lubricating pumps.

For facilities that do not want to spend the time to check the user manual for every pump and then lubricate every bearing, A.W. Chesterton offers the Lubri-cup as the perfect solution. This device automatically dispenses the preprogrammed amount of lubrication to the pump. One Lubri-cup can reduce a facilities manager’s workload by two days, which means your team can spend more time on other tasks than just lubricating pumps.

the Diamond Warranty*. It covers most Sullair compressor units with a discharge pressure of 150 PSIG or less. The warranty covers all major components for new air compressors, including 10 years on the air end plus 5 years on the motor and other components such as the air/fluid receiver, oil cooler, and aftercooler. The extent of warranty coverage shows how confident Sullair is in the longevity of its products.

the Diamond Warranty*. It covers most Sullair compressor units with a discharge pressure of 150 PSIG or less. The warranty covers all major components for new air compressors, including 10 years on the air end plus 5 years on the motor and other components such as the air/fluid receiver, oil cooler, and aftercooler. The extent of warranty coverage shows how confident Sullair is in the longevity of its products.

Northwest Pump offers service intervals every 2,000 hours or three months, whichever is first, or at other mutually agreed upon and set intervals. We also provide an annual service interval every 4,000 to 8,000 hours depending on lubricants in your compressor, or once a year, whichever is first. These service appointments include a complete visual inspection, an oil level check, inspection of air filter & change (if appropriate), oil filter replacements (if applicable), check separators’ differential pressures, checking oil return lines & valves, checking operating temperatures & cooling systems, control inspection, air discharge inspection & adjustment (if appropriate), an inspection of belt tension, electrical system check with amp draws & voltage, air dryer & filtration inspection, and a checklist of all components inspected and or serviced.

Northwest Pump offers service intervals every 2,000 hours or three months, whichever is first, or at other mutually agreed upon and set intervals. We also provide an annual service interval every 4,000 to 8,000 hours depending on lubricants in your compressor, or once a year, whichever is first. These service appointments include a complete visual inspection, an oil level check, inspection of air filter & change (if appropriate), oil filter replacements (if applicable), check separators’ differential pressures, checking oil return lines & valves, checking operating temperatures & cooling systems, control inspection, air discharge inspection & adjustment (if appropriate), an inspection of belt tension, electrical system check with amp draws & voltage, air dryer & filtration inspection, and a checklist of all components inspected and or serviced.

You can contact us for your next slurry pumping solution

You can contact us for your next slurry pumping solution

While these pumps are certainly beneficial for some situations, they are not ideal for every pumping situation. Instead of choosing from the above ANSI specifications, a facility might desire a more robust approach. One such option may be

While these pumps are certainly beneficial for some situations, they are not ideal for every pumping situation. Instead of choosing from the above ANSI specifications, a facility might desire a more robust approach. One such option may be