Mar 22, 2023 | Industrial, Services

When it comes to food production, there are strict standards during the manufacturing process to maintain safety standards. With smooth internal surfaces & ease of cleaning, sanitary pumps meet these requirements to protect against bacteria and other contaminants. Northwest Pump offers several sanitary pump options for many different applications, whether it be for a thick yogurt slurry or freshly pressed oil.

Do all pumps in a plant need to be sanitary pumps?

No, not all pumps in a food production plant need to be sanitary. A sanitary pump is only necessary when it is in direct contact with food products. Grundfos, for example, does not offer sanitary pumps. What it offers instead is pressure-boosting equipment as well as pumps to clean out the sanitary equipment already present in a facility.

What makes equipment sanitary?

3-A symbol from the International Association of Milk, Food, and Environmental Standards

The FDA regulates Food Contact Substances (FCS) ranging from the pumping equipment processing the food, to the coverings on an at-home coffee machine. The key feature of sanitary equipment is a smooth surface that can be easily cleaned. Manufacturers of sanitary pumps can offer easily disassembled pumps to increase the ease of cleaning, depending on the brand. A sanitary pump will typically be made of stainless steel 316A, or alternatively will be made of a non-porous plastic. The International Association of Milk, Food, & Environmental Standards also has a symbol called 3A to show when a pump meets these classifications. This and the FDA logos will appear on pump literature when the product meets these requirements.

Are sanitary & hygienic the same thing?

The main difference between hygienic and sanitary equipment is in their applications. The FDA classification for sanitary pumps must meet higher standards for consumer product manufacturing. Hygienic pumps on the other hand, are for high-volume transfer applications for food & beverage, cosmetics, and even pharmaceutical processing.

Our Sanitary Products

Northwest Pump offers sanitary & hygienic pumps for a variety of applications. Our main vendor for sanitary pump equipment is PSG, a Dover Company, through its Wilden, Mouvex, and Abaque brands. We now also offer vacuum pumps through Atlas Copco, for canning and other sanitary applications. In addition to these pumps, Northwest Pump now offers food-grade valves, fittings, and other ancillary pumping equipment through Dixon Valve & Fitting. For food-grade lubricants, we have partnered with A.W. Chesterton Company. Finally, for food-safe compressed air, Northwest Pump offers oil-free compressors through Sullair.

Next Steps

Need a sanitary pump for your facility? You can contact our experts here, email them at sales@nwpump.com, or call 1-800-452-PUMP to discuss your application needs. Looking for service on your current sanitary pumps? Reach our service team here, email them at service@nwpump.com, or call 1-866-577-2755.

Dec 5, 2022 | Industrial, Services

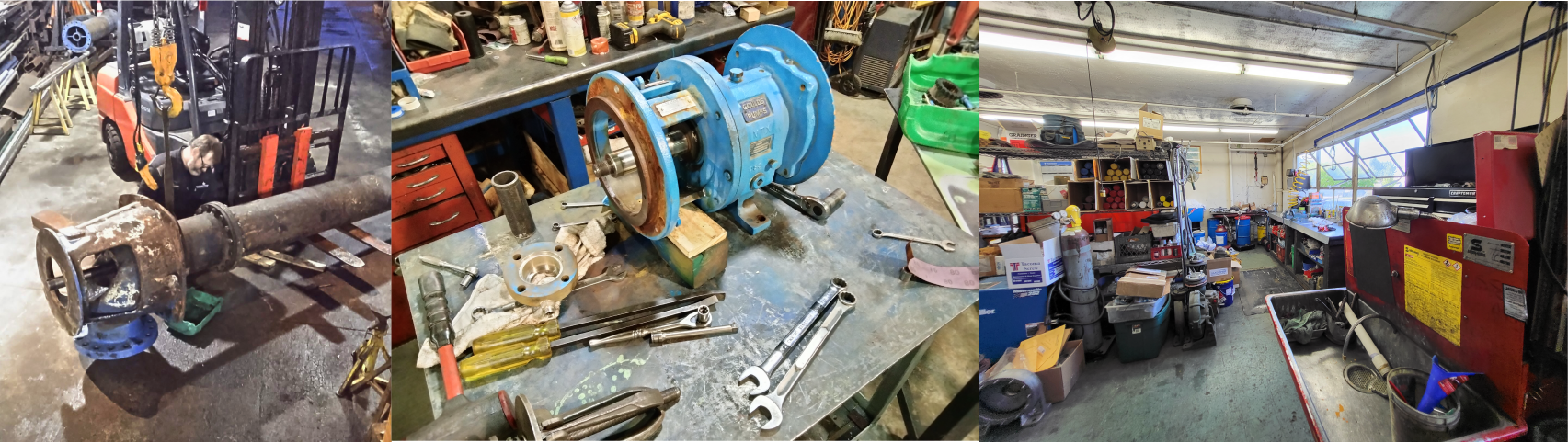

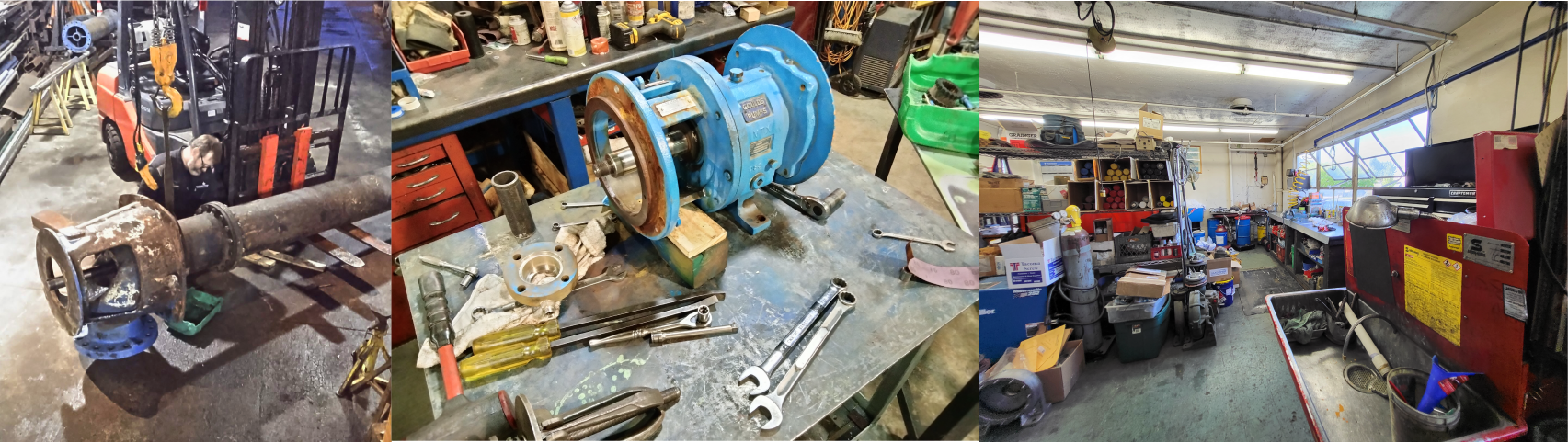

Over the last few months, our Industrial service team has been working on revitalizing the Portland branch’s in-house pump shop. The end goal of this project is to build the most respected industrial pump repair shop in the country. Northwest Pump is committed to servicing your industrial equipment needs, and now we will expand our capabilities even further.

Learning from the best

Our team realized the best way to start this journey was to look at other renowned pump shops across the United States to compare what they have, to where we want to be. With help from A.W. Chesterton, the team was able to visit pump fabrication facilities in the south-eastern US. This helped us know not only the type of equipment they utilize, but also the layout of the shop as well as the technical know-how our team needed to consider.

What to expect from the new pump shop

When the renovations are finished, Northwest Pumps’ repair shop will be assembling pump packages in-house. The packages will have Chesterton seals or packing as needed and be engineered with customer need first. We will also be able to increase production in compressor packages manufactured in-house as well.

In addition to assemblies, the shop will add an inside overhead crane to expand our capabilities when working with larger turbine pumps. The shop is also upgrading its dynamic balancer for more precise insights on the balance of the impellers that we work with.

What is new?

In the time since the trip, our shop has upgraded its tool boxes for increased capacity & ease of use. Those visiting our Portland branch for any will calls should notice the warehouse now starting to make space for upcoming pump assemblies already. As we begin the process of updating the shop, we expect no impacts to repair times.

In the time since the trip, our shop has upgraded its tool boxes for increased capacity & ease of use. Those visiting our Portland branch for any will calls should notice the warehouse now starting to make space for upcoming pump assemblies already. As we begin the process of updating the shop, we expect no impacts to repair times.

Next Steps

Stay tuned for updates through social media or sign up for our service newsletter to receive them monthly below.

Looking for maintenance on your industrial pumps? Request an appointment here.

Oct 31, 2022 | Services

Secure your competitive advantage and increase profits with Gilbarco’s Encore 700 EMV Fuel Dispenser – your best dispenser investment for today and tomorrow. With a familiar ATM-style customer interface, the highly secure CRIND provides enhanced, upgradable security that supports EMV and contactless payment technologies.

Forecourt Payment and Merchandising

Encore 700 S gives you field-proven tools to inform, persuade, and motivate your fuel customers to come inside your store and buy higher-margin goods, through:

- Flexible content management options, with the industry-leading Applause® Media System

- Superior on-screen image clarity, video resolution, and video performance

- Supports mobile payment applications

- Capability to support EMV Contactless payment

- 10.4″ color screen for maximum impact

Aging Equipment Is Expensive

Parts, service, and labor costs are increasing. It’s time to invest in an asset that pays you back. Save your cash and finance EMV technology upgrades at below-market rates.

Forecourt Payment Security: FlexPay™ IV is the industry’s most secure payment platform for fuel dispensers. The FlexPay IV CRIND provides the easiest and most integrated secure payment solutions.

Forecourt Engagement: Encore 700 S gives you field-proven tools to inform, persuade, and motivate your fuel customers to come inside your store and buy higher-margin goods.

Dispenser Fueling Security: Offers customizable security options such as custom locks, door entry detection sensors, reinforced lower panels, or encrypted pulsers.

Dispenser Remote Management: Gilbarco’s cloud-based service, Insite360 Encore, allows subscribers to remotely connect to their dispensers and perform several straightforward and complex tasks.

Secure. Connected. Profitable.

The stakes have never been higher when it comes to security on the fuel island. Gilbarco’s FlexPay systems and contactless payment technology make EMV upgrades and mobile payments easier and more cost-effective.

Self-Managed Media To Drive Forecourt Engagement

Boost your business and drive fueling customers inside your store with valuable solutions that enhance your digital strategy on the forecourt. Encore’s media solutions engage your customers at the pump, improve brand loyalty, and increase your bottom line.

Next Steps

It’s time to enhance customer engagement and scale your digital transformation with robust loyalty and content management options. Learn more about the Encore 700 EMV Fuel Dispenser by contacting sales@npwump.com, calling 1-800-452-PUMP, or finding your nearest location here.

Oct 11, 2022 | Industrial, Services

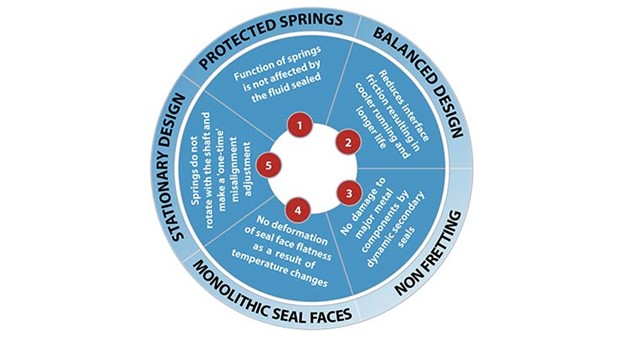

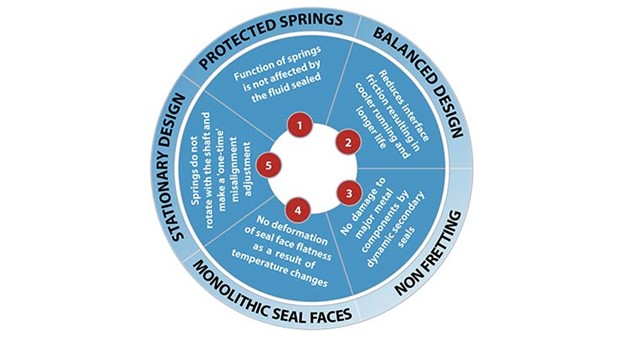

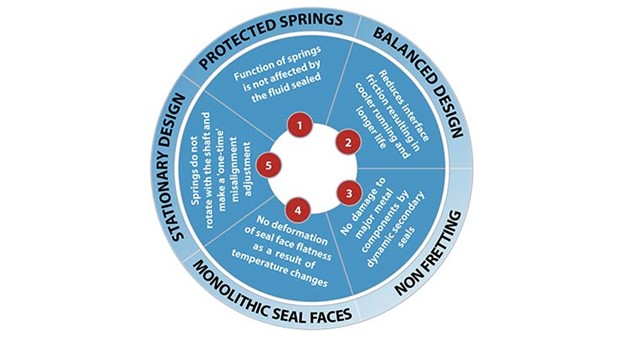

A crucial step in preventative maintenance in pumps is finding and using the correct seal for the job. Mechanical seals are used to seal the rotating shaft in pumps and other equipment. With so many mechanical seal designs on the market, it can be difficult to identify which kinds to use. A.W. Chesterton Company’s mechanical seal design utilizes 5 design principles to maximize its sealing capabilities. These principles have been refined by Chesterton since the company brought its first mechanical seal to market in 1970. After all the lessons learned from successes and failures, they have determined the Five Key Features that a mechanical seal should have to reduce unplanned maintenance and downtime. To provide the greatest mean time between failures (MTBF) and avoid downtime, they utilize these five design principles in their sealing devices.

Protected Springs

Spring protected from fluids | Image provided by A.W. Chesterton Company

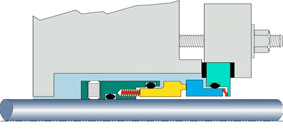

Typically, within early mechanical seal designs, the springs were submerged within the fluid. However, this can lead to trouble when fluids with dirt or other contaminates interact with the springs. When the contaminates collect within the spring, it cannot correctly maintain the alignment necessary for a complete seal. Chesterton’s mechanical seal design protects the springs within the mechanical seal from the fluids being pumped.

Balanced Design

The second design feature and open secret of Chesterton’s mechanical seal design is balance. On the mechanical seal, there are two main sides, the fluid side, and the atmospheric side. To prevent moisture from leaking out of the seal, both sides put equal pressure on each other to trap the fluid. Many seals will often see that the fluid side exerts greater pressure than the atmospheric side. Not only does this reduce the quality of the seal, but it can also ruin the pump with time. Balanced seals reduce the seal ring area on which the hydraulic pressure of the liquid in the pump acts. This allows for better lubrication that results in lower heat generation, face wear, and power consumption. Balanced seals will generally have higher pressure ratings than unbalanced seals.

Non-fretting

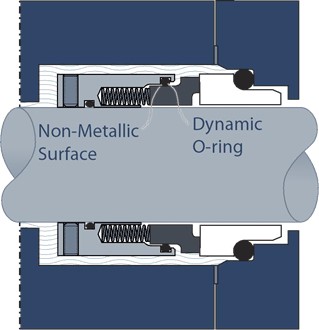

Non-Fretting Seal | Image provided by A.W. Chesterton Company

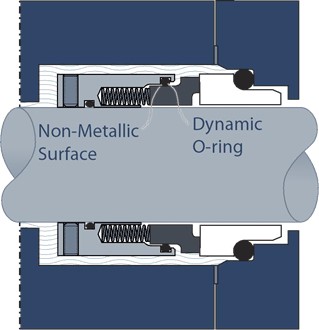

Fretting on a pump shaft refers to the way that a material is worn away on a shaft by an elastomeric material. An example may be a 316 stainless steel shaft sleeve that is damaged by a Viton O-ring. Stainless steel protects a shaft from corrosion by forming a chrome oxide layer on the surface. The dynamic O-ring wears that protective surface away and it then reforms. Over time the chrome oxide gets imbedded into the O-ring and works like sandpaper removing even more material. The result is a groove worn into your expensive sleeve and a leaking mechanical seal. Chesterton seals utilize designs that have any dynamic O-rings operating against a non-metallic surface, usually the sacrificial face.

Additionally, some manufacturers offer seals that are self-fretting, rather than shaft-fretting. What this means is that these seals do not fret or damage the shaft, they harm seal itself. While this protects the pumps, the O-rings still work against metal, reducing the lifespan of the seal itself.

Monolithic Seal Faces

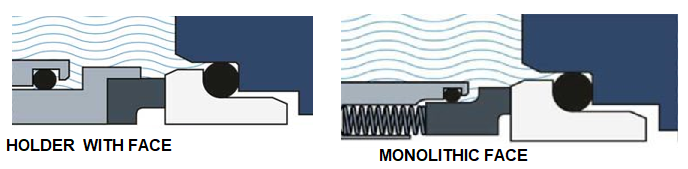

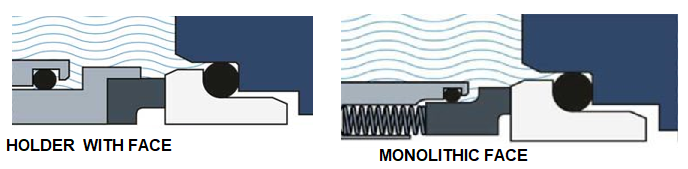

Inserted vs Monolithic Seal Face | Image provided by A.W. Chesterton Company

Some mechanical seal designs utilize an inserted seal face, typically made of carbon or graphite inserted into a metal holder. However, the disadvantage to this technique is these non-metallic materials often react to heat differently than the metal of the seal. The result is the face of the seal is easily deformed- leading to leaks and early replacement of the seal. Proper mechanical seal design uses monolithic seal faces without using a holder and inserted face. By using Finite Element Analysis (computer modeling), Chesterton’s monolithic seal face designs are made more efficiently than ever.

Stationary Design

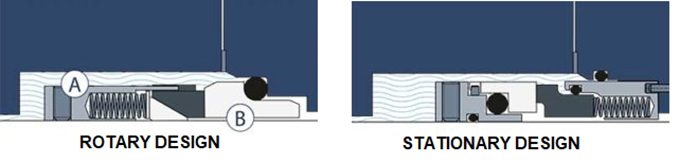

Rotary vs Stationary Seals | Image provided by A.W. Chesterton Company

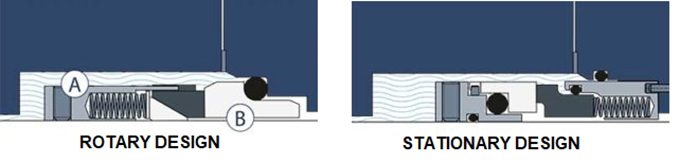

Mechanical seals can either use rotating or stationary springs. With rotary mechanical seals, it is important that the stuffing box face is perpendicular to the shaft for the faces to stay closed. There will always be some resulting misalignment from installation and parts tolerances so this alignment cannot be assured. To compensate for the misalignment, the springs must adjust each time the shaft rotates to keep the seal faces closed. At motor speeds this adjustment happens thousands of times per minute (for 1800 rpm, 3600 adjustments occur) which is not only difficult to accomplish, the springs will fatigue and fail causing seal failure. Rotary seals are simple in design which makes them inexpensive

In contrast, a stationary seal is designed in such a way that the springs do not rotate with the pump shaft; they remain stationary. Because the springs do not rotate, they are unaffected by the rotation of the shaft or how fast the shaft rotates. The springs do not need to correct or adjust with each rotation; they adjust for misalignment only once when installed. Chesterton uses this as the fifth design requirement, and this provides greater life to their mechanical seals.

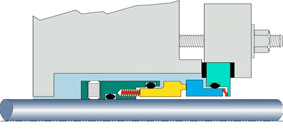

Chesterton 1510L in Action

Using these five design principles, Chesterton has updated its 150 seals to the new 1510 seal. The new design uses a monolithic seal face and changes where the dynamic O-rings are placed to be a non-fretting seal. Chesterton unveiled this updated seal in the US in September of 2022. However, Chesterton also has one additional add-on for this new seal. Starting at the end of October 2022, Chesterton will be releasing the 1510L. The 1510L has all the same design capabilities of the 1510, the difference between the two is the installation process. The 1510L utilizes a lock ring mechanism to simplify installation requiring the installer to tighten only one screw to connect the seal to the shaft.

Next Steps

To request a demonstration for the 1510L mechanical seal, click here. Learn more about Northwest Pump’s mechanical seals by contacting us here, emailing us at sales@nwpump.com, or by calling 1-800-452-PUMP.

For service on your mechanical seals by our Chesterton certified pump technicians, contact us here, email us at service@nwpump.com, or call 1-866-577-2755.

Jul 1, 2022 | Industrial, Services

Brand Spotlight: Wilo

Starting on July 1st this year, Northwest Pump is now partnering with Wilo to become an authorized service provider for Wilo brand pumps. In addition to selling Wilo & American-Marsh, Northwest Pump will now add Scot Pump, Weil Pump, & QuantumFlo to our list of vendors. We are also bringing Wilo and Wilo brand pumps to our Fresno branch. Here is a guide to Wilo, their brands, and the products & solutions they offer.

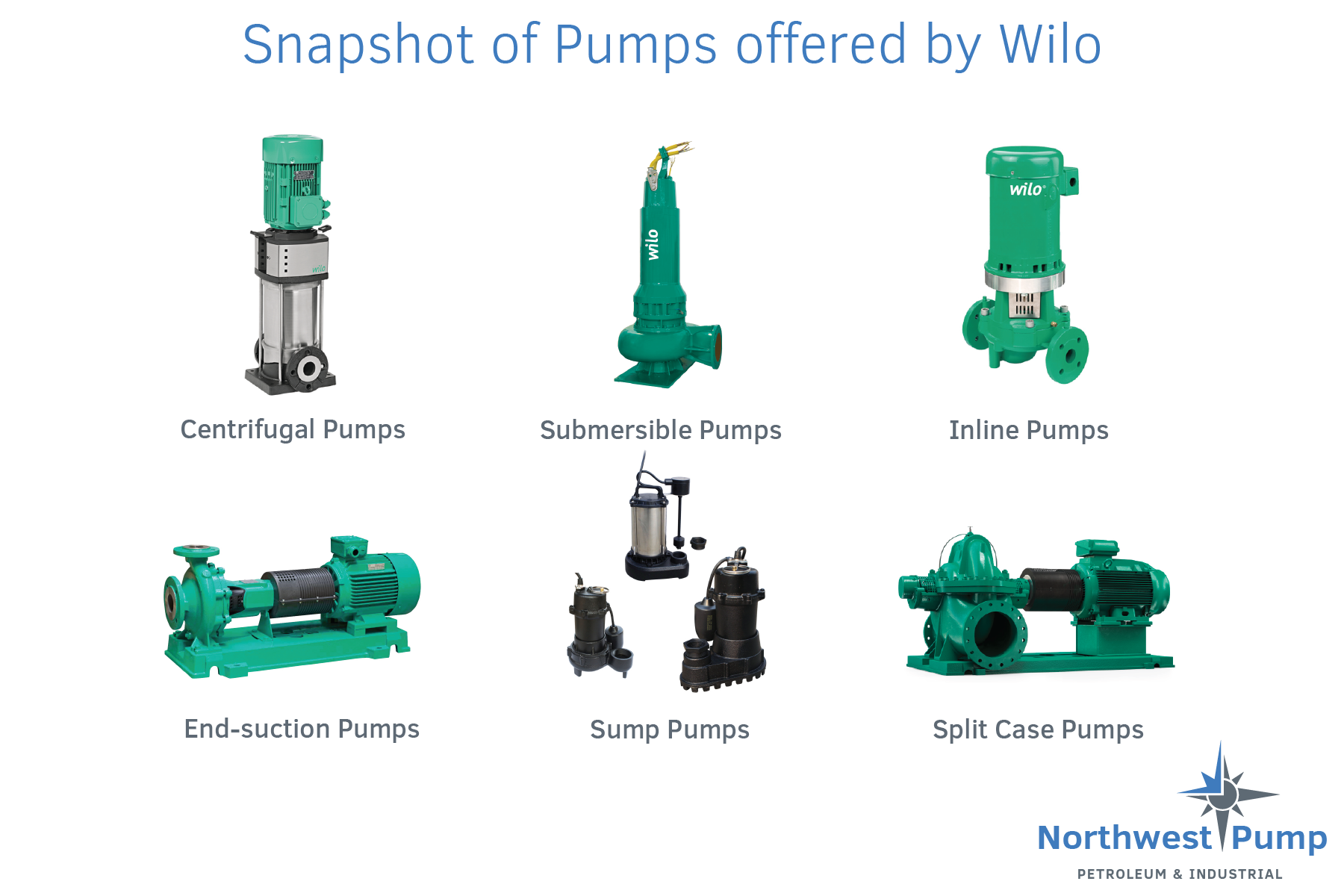

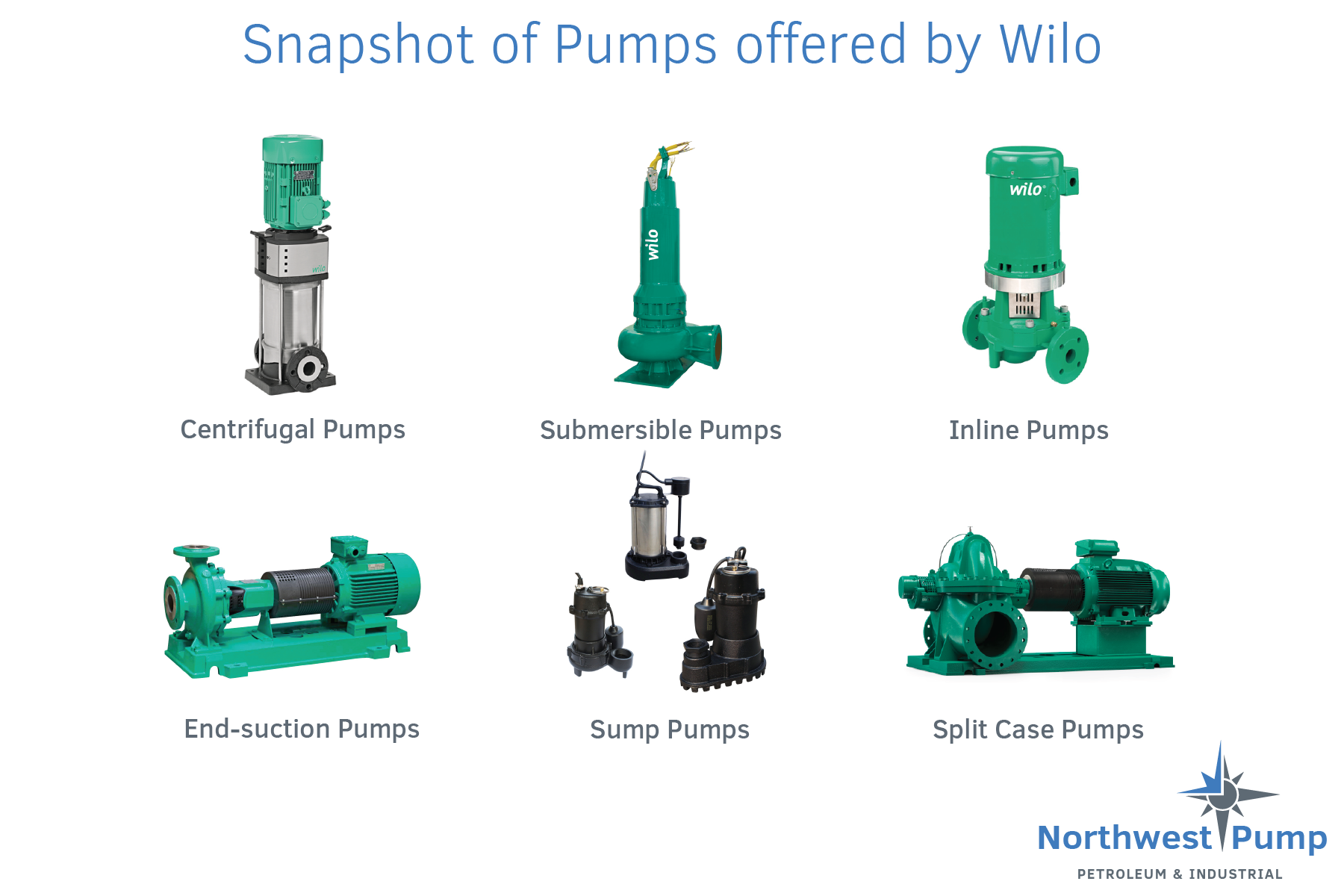

Wilo Pumps & Other Products

Wilo offers centrifugal, sump, in-line, end suction, split case, and submersible pumps for HVAC, water supply, drainage, and sewage. Many of Wilo’s centrifugal pumps are also ANSI and NSF certified. Additionally, Wilo also provides circulators, boosting systems, pressure tanks, and individual parts for aftermarket repairs.

Wilo’s Other Brand Pumps

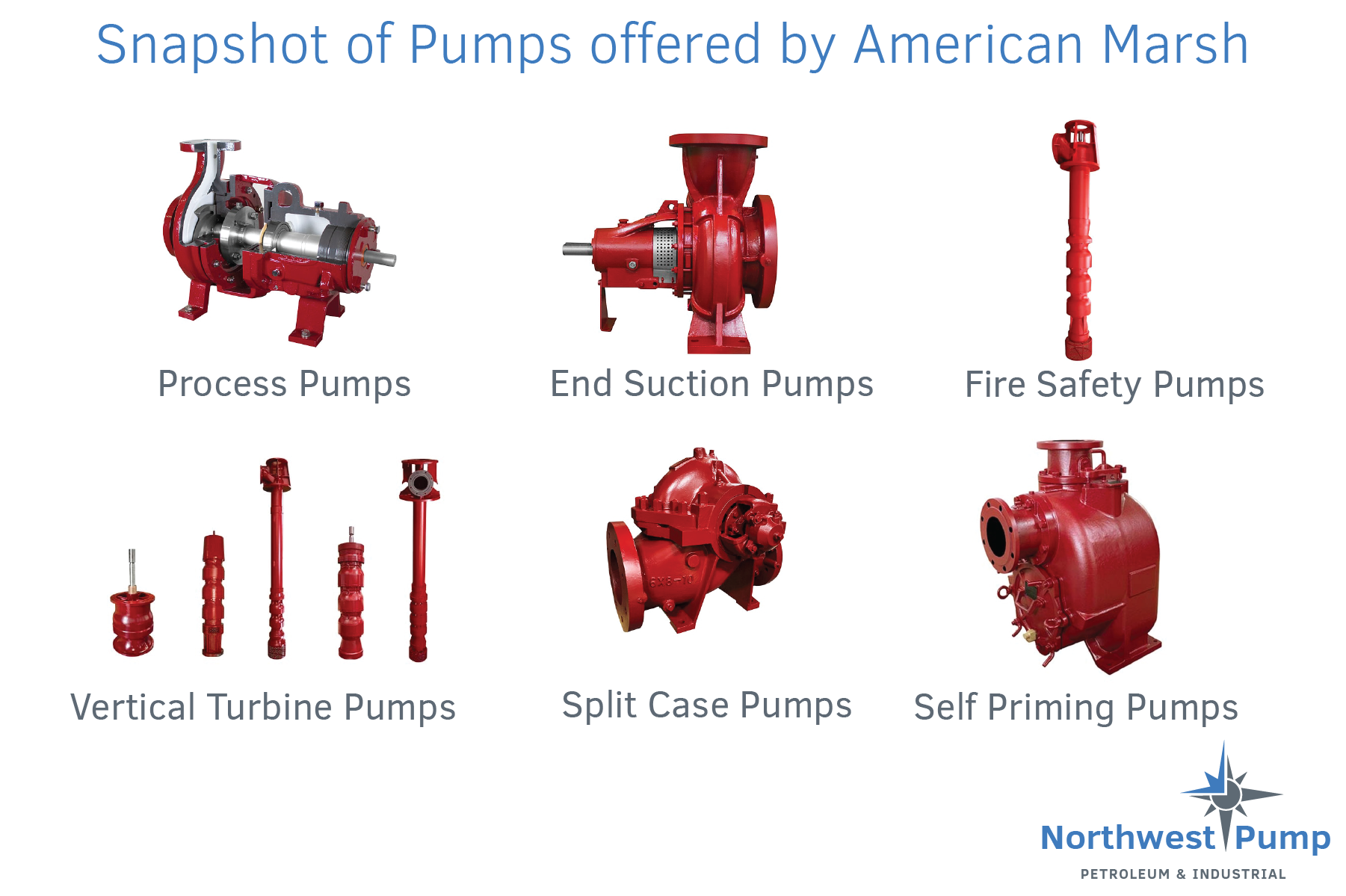

American-Marsh Pumps

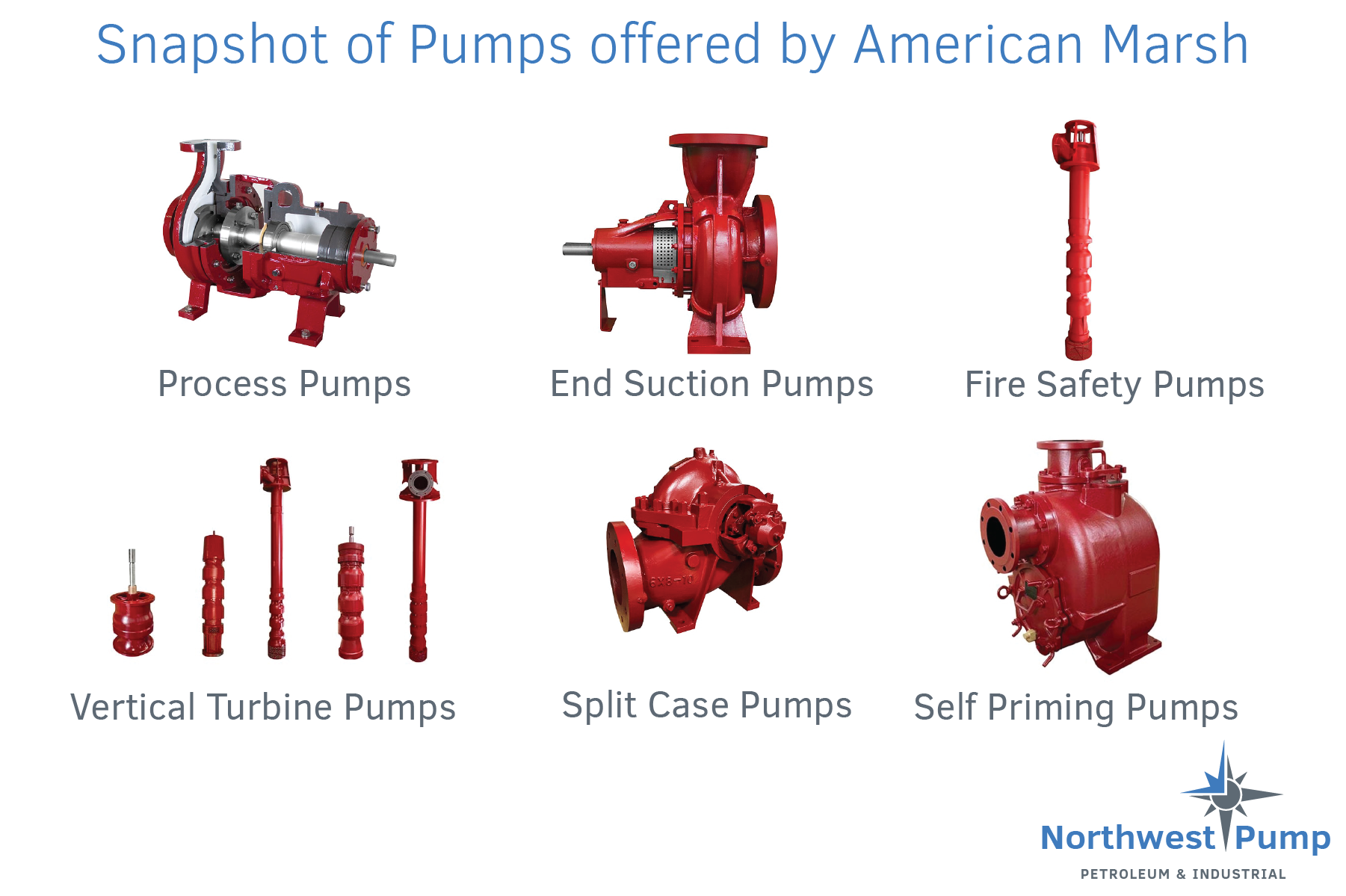

American-Marsh offers end suction, process sump, self-priming, split-case, ANSI process pumps, and vertical and submersible turbine pumps. Besides their pump offerings, American-Marsh also sells mechanical seals, electrical motors, and other fire protection equipment. This brand serves industrial, municipal, agricultural, commercial, & fire-protection markets.

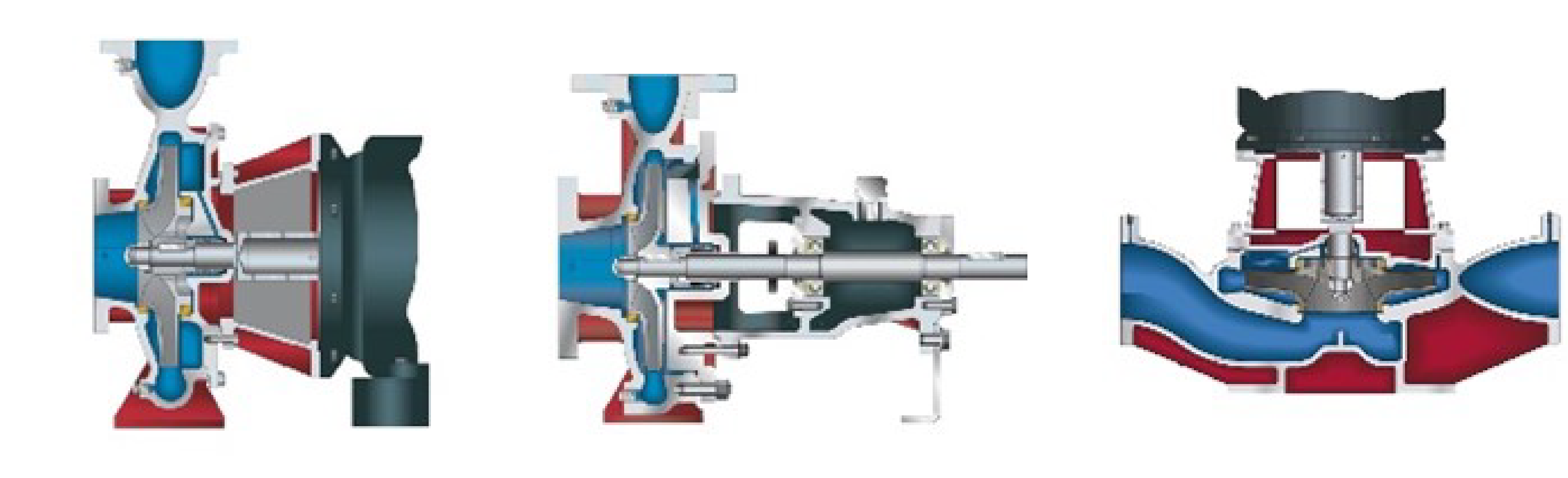

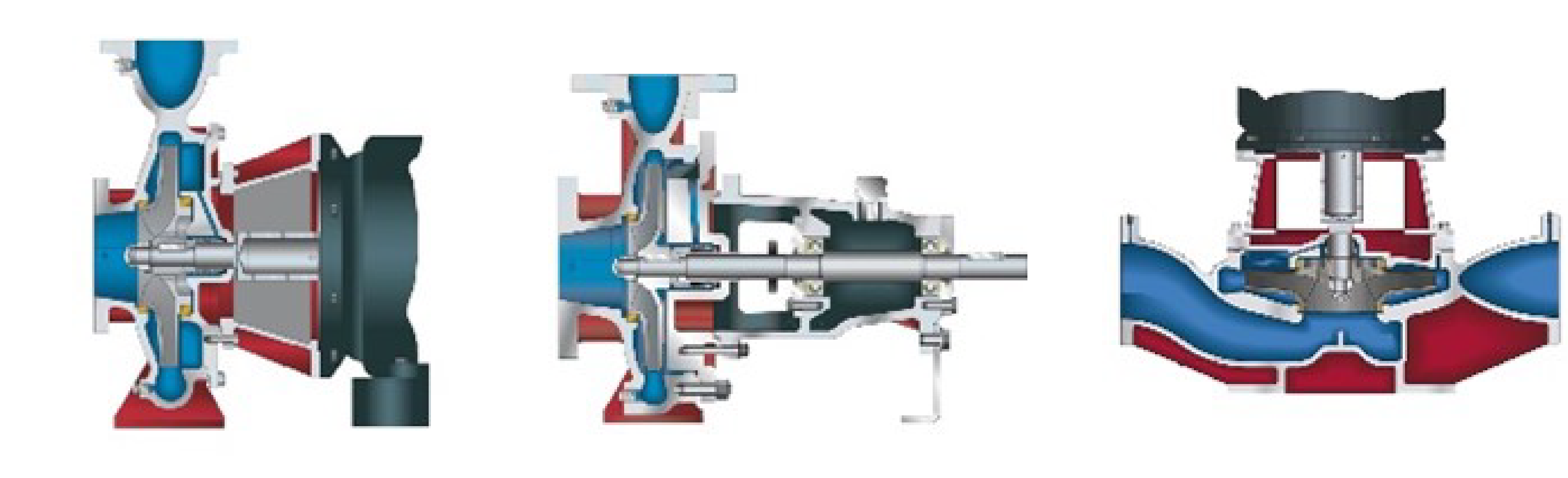

Diagram of Close & Flex-Coupled/Inline End Suction Pumps

Scot Pump

Scot Pump focuses on end suction single-stage centrifugal pumps designed for several applications. The uses range from industrial plants, temperature controllers, truck-mounted, marine environments, and outdoor rooftops, to name just a few. This manufacturer uses various materials such as iron, bronze, aluminum, and stainless steel.

Scot Pump focuses on end suction single-stage centrifugal pumps designed for several applications. The uses range from industrial plants, temperature controllers, truck-mounted, marine environments, and outdoor rooftops, to name just a few. This manufacturer uses various materials such as iron, bronze, aluminum, and stainless steel.

Weil Pump

Weil specializes in centrifugal pumps. This brand offers submersible, grinder, sump, sewage, and dry well pumps, turbine condensate return pumps, booster systems, control panels, and other pumping accessory equipment.

Weil specializes in centrifugal pumps. This brand offers submersible, grinder, sump, sewage, and dry well pumps, turbine condensate return pumps, booster systems, control panels, and other pumping accessory equipment.

QuantumFlo

QuatumFlo is the newest Wilo brand, and its focus is on packaged pumping systems. This brand not only manufactures pumps, it also offers software to maximize the efficiency of pump systems as well.

Next Steps

Did a product listed above catch your eye? Check out Wilo’s complete catalog with all four brands mentioned here.

Ready to inquire about Wilo pumps? Email our team for the next steps and other information by emailing sales@nwpump.com, calling us at 1-800-452-PUMP, or contacting us here. Does your Wilo brand pump need service? You can access our official Wilo service center pump shop by requesting service here, emailing service@nwpump.com, or calling 1-866-577-2755.

Jun 8, 2022 | Industrial, Services

One of the many ways a facility can become more environmentally friendly is changing how they receive its compressed air. Using the wrong compressor can mean less efficient production and more energy waste. On the other hand, improperly running the right air compressor can also waste energy. Here are a few ways to make your facility a little more green with Sullair.

Air Compressor Longevity

Since 1965, Sullair has been known for durable air compressors. Driven by a legendary air end design, Sullair builds its compressors to last. A Sullair unit can reliably run more than seventy-thousand hours before needing to be replaced. To put this into perspective: a typical 40-hour workweek means an average of 2,080 hours in a year. With the right maintenance, lubrication, and compressed air system in place, a compressor from Sullair can last even over one hundred thousand hours.

Sullair’s Sustainable Equipment Offerings

The two best Sullair air compressor series for being environmentally friendly are the S-Energy and the DSP series. Both compressors have Variable Speed Drives (also referred to as VDS). This allows the compressor to control the motor’s speed at many different levels instead of one precise point, which can increase the energy efficiency of the air compressor in the right circumstances. This means you only pay to compress the air you need, which helps increase energy efficiency and saves you money. Those interested in VDS compressors but do not have enough need for it can also consider having a spiral valve on their compressor.

The DSP Series

The DSP series is oil-free, meaning that the oil does not encounter the air being compressed. In fact, the DSP series has ISO 8573-1 Class Zero air, which means that this air surpasses Class 1 qualifications- all without needing as much additional filtration equipment as oil flooded compressors. This eliminates the chance of oil damaging sensitive machinery through the air and makes the condensate byproduct safer for disposal. When air purity is critical, the DSP series is a great choice.

The DSP series is oil-free, meaning that the oil does not encounter the air being compressed. In fact, the DSP series has ISO 8573-1 Class Zero air, which means that this air surpasses Class 1 qualifications- all without needing as much additional filtration equipment as oil flooded compressors. This eliminates the chance of oil damaging sensitive machinery through the air and makes the condensate byproduct safer for disposal. When air purity is critical, the DSP series is a great choice.

All DSP compressors come with an oil-demister, which further retains the oil used to make it even more efficient. Another feature the DSP series offers is the patented high pre-cooler design. This prevents premature after-cooler failure and increases the durability of the compressor further. Another feature of the DSP series compressor is the optimized rotor design. Typically, oil-free compressors use PTFE. However, with proprietary MOS2 coating, Sullair maximizes the lifespan of the air-end and protects your investment. Finally, a standard DSP series compressor has a totally enclosed, fan-cooled (TEFC) motor and an optional NEMA 4 Wye-Delta starting cabinet. The TEFC motor means that outside contaminants do not enter the machine, which prevents long-term damage, and the NEMA 4 starting cabinet further protects against dust & harsh weather.

The S-Energy Series

While the S-Energy compressor series is oil-flooded, meaning that oil mixes with compressed air and the condensate, there are ways to minimize harm to the environment and increase efficiency. Sullair S-energy compressors are engineered for reliability, durability, and performance. These units can help you optimize efficiency and are in for the long haul. They can last up to 100,000 working hours if you treat them right.

While the S-Energy compressor series is oil-flooded, meaning that oil mixes with compressed air and the condensate, there are ways to minimize harm to the environment and increase efficiency. Sullair S-energy compressors are engineered for reliability, durability, and performance. These units can help you optimize efficiency and are in for the long haul. They can last up to 100,000 working hours if you treat them right.

S-Energy units come standard with a TEFC motor & NEMA 4 Wye-Delta starting cabinet, just like the DSP. Additionally, Sullair used their fifty-five years of experience designing lasting air-ends to maximize the lifespan of the S-Energy compressors. An S-Energy unit can easily last for seventy, eighty, or even one hundred thousand working hours with the correct maintenance. The last standard S-Energy sustainability feature is the WS control system. Its enhanced functionality means that an operator can receive energy usage reports on their computer, tablet, or smartphone and better control the outputs of their compressor.

Sustainable Air Compressor Attachments

Sullair offers many auxiliary products to help keep your operation environmentally friendly. Northwest Pump recommends the following products to help optimize energy efficiency and improve the longevity of your compressor and its components and other equipment and products.  First, help separate harmful oil from condensate by using an oil/water separator. This keeps the condensate safe for drains, pipes, and accidental spills and allows for safer oil disposal.

First, help separate harmful oil from condensate by using an oil/water separator. This keeps the condensate safe for drains, pipes, and accidental spills and allows for safer oil disposal.

The following sustainable attachment is the SULLIMAX Condensate Drain. It works using an automatic drain to remove condensate at a specific temperature without releasing compressed air. This reduces compressor maintenance and reduces energy use, and maximizes savings. According to Sullair’s trials, a facility could see a return on investment for the SULLIMAX in 150 days.

Finally, every compressor needs fluid or oil to keep it running, and Sullube is one of the top compressor fluids on the market. It protects the Diamond warranty on the S-Energy series and is also biodegradable. This means that handling or disposing of condensate with Sullube is faster, safer, & cheaper. Another feature of Sullube is that it is non-varnishing and cleans existing varnish off surfaces.

What Northwest Pump does to keep your equipment sustainable

Northwest Pump has a few tricks up our sleeve to lower your carbon footprint as much as possible. Our technicians and representatives offer site & utility assessments for new projects. These audits can determine how much a facility will spend on utilities & how to minimize pain points in the production flow. From there, we can offer customizable solutions to serve the needs of our customers best. Additionally, our service team provides customizable rotating equipment service plans. These plans mean our service technicians arrive at your facility and maintain your air compressors and pumps. Our service team also offers recycling services for air compressor filters & oil.

Next Steps

Looking for your sustainable equipment solution? Start the conversation by emailing us at sales@nwpump.com or calling 1-800-452-PUMP. Interested in our service capabilities? Reach out here for service requests or call 1-866-577-2755.

In the time since the trip, our shop has upgraded its tool boxes for increased capacity & ease of use. Those visiting our Portland branch for any will calls should notice the warehouse now starting to make space for upcoming pump assemblies already. As we begin the process of updating the shop, we expect no impacts to repair times.

In the time since the trip, our shop has upgraded its tool boxes for increased capacity & ease of use. Those visiting our Portland branch for any will calls should notice the warehouse now starting to make space for upcoming pump assemblies already. As we begin the process of updating the shop, we expect no impacts to repair times.

Scot Pump focuses on end suction single-stage centrifugal pumps designed for several applications. The uses range from industrial plants, temperature controllers, truck-mounted, marine environments, and outdoor rooftops, to name just a few. This manufacturer uses various materials such as iron, bronze, aluminum, and stainless steel.

Scot Pump focuses on end suction single-stage centrifugal pumps designed for several applications. The uses range from industrial plants, temperature controllers, truck-mounted, marine environments, and outdoor rooftops, to name just a few. This manufacturer uses various materials such as iron, bronze, aluminum, and stainless steel. Weil specializes in centrifugal pumps. This brand offers submersible, grinder, sump, sewage, and dry well pumps, turbine condensate return pumps, booster systems, control panels, and other pumping accessory equipment.

Weil specializes in centrifugal pumps. This brand offers submersible, grinder, sump, sewage, and dry well pumps, turbine condensate return pumps, booster systems, control panels, and other pumping accessory equipment.

The DSP series is oil-free, meaning that the oil does not encounter the air being compressed. In fact, the DSP series has ISO 8573-1 Class Zero air, which means that this air surpasses Class 1 qualifications- all without needing as much additional filtration equipment as oil flooded compressors. This eliminates the chance of oil damaging sensitive machinery through the air and makes the condensate byproduct safer for disposal. When air purity is critical, the DSP series is a great choice.

The DSP series is oil-free, meaning that the oil does not encounter the air being compressed. In fact, the DSP series has ISO 8573-1 Class Zero air, which means that this air surpasses Class 1 qualifications- all without needing as much additional filtration equipment as oil flooded compressors. This eliminates the chance of oil damaging sensitive machinery through the air and makes the condensate byproduct safer for disposal. When air purity is critical, the DSP series is a great choice. While the S-Energy compressor series is oil-flooded, meaning that oil mixes with compressed air and the condensate, there are ways to minimize harm to the environment and increase efficiency. Sullair S-energy compressors are engineered for reliability, durability, and performance. These units can help you optimize efficiency and are in for the long haul. They can last up to 100,000 working hours if you treat them right.

While the S-Energy compressor series is oil-flooded, meaning that oil mixes with compressed air and the condensate, there are ways to minimize harm to the environment and increase efficiency. Sullair S-energy compressors are engineered for reliability, durability, and performance. These units can help you optimize efficiency and are in for the long haul. They can last up to 100,000 working hours if you treat them right. First, help separate harmful oil from condensate by using an oil/water separator. This keeps the condensate safe for drains, pipes, and accidental spills and allows for safer oil disposal.

First, help separate harmful oil from condensate by using an oil/water separator. This keeps the condensate safe for drains, pipes, and accidental spills and allows for safer oil disposal.