Summer is just around the corner, and with the change in season, now is the perfect time to check your entire facility and prevent emergencies before they happen. Here are ten ways to check the health of your pumps and air compressors and a pair of seasonal facility maintenance checklist printouts below to keep on hand.

Compressor Checklist

□ Change your oil

Whether a compressor is oil-flooded or oil-free , the start of a new season is the perfect time to refresh the oil on a compressor. Keep in mind, that some brands need specific lubricants. For example, Sullair compressors need genuine Sullube to keep within warranty. Additionally, why not conduct an oil sampling? This also protects the diamond warranty, and lets you know about the health of your compressor.

, the start of a new season is the perfect time to refresh the oil on a compressor. Keep in mind, that some brands need specific lubricants. For example, Sullair compressors need genuine Sullube to keep within warranty. Additionally, why not conduct an oil sampling? This also protects the diamond warranty, and lets you know about the health of your compressor.

□ Check your oil cooler & aftercooler

One of the many uses of oil in the compressor is to reduce the heat within the machine. This process protects the machinery from unnecessary damage, and why checking the oil cooler & aftercooler should be on your list.

□ Check your package air inlet filters

The easiest way to check if the package air inlet filter needs a replacement is by hovering your hand over the top of the compressor. If you feel a breeze, then your inlet filter is working just fine. If there is a weak breeze or none at all, it’s time for the filter to be cleaned or replaced. This check is especially helpful for compressors that are in environments with more dust or other particles in the air that can clog up filters.

air inlet filter needs a replacement is by hovering your hand over the top of the compressor. If you feel a breeze, then your inlet filter is working just fine. If there is a weak breeze or none at all, it’s time for the filter to be cleaned or replaced. This check is especially helpful for compressors that are in environments with more dust or other particles in the air that can clog up filters.

□ Check the make-up air

In a similar vein, checking the room a compressor is in is also important. The three points to consider are: making sure that the air surrounding the air compressor (make-up air) is free of particles and other contaminants, making sure that make-up air is adequate, and making sure that the temperature in the room can withstand compressed air that is 15°F higher than the ambient temperature.

In a similar vein, checking the room a compressor is in is also important. The three points to consider are: making sure that the air surrounding the air compressor (make-up air) is free of particles and other contaminants, making sure that make-up air is adequate, and making sure that the temperature in the room can withstand compressed air that is 15°F higher than the ambient temperature.

If you don’t have a manometer to check the adequacy of your make-up air, one easy test is to test the compressor room door. Is it difficult to open when you open the door, or does it try to slam shut when you let go? If so, you should consider consulting one of our specialists to help you redesign your make-up air to the room.

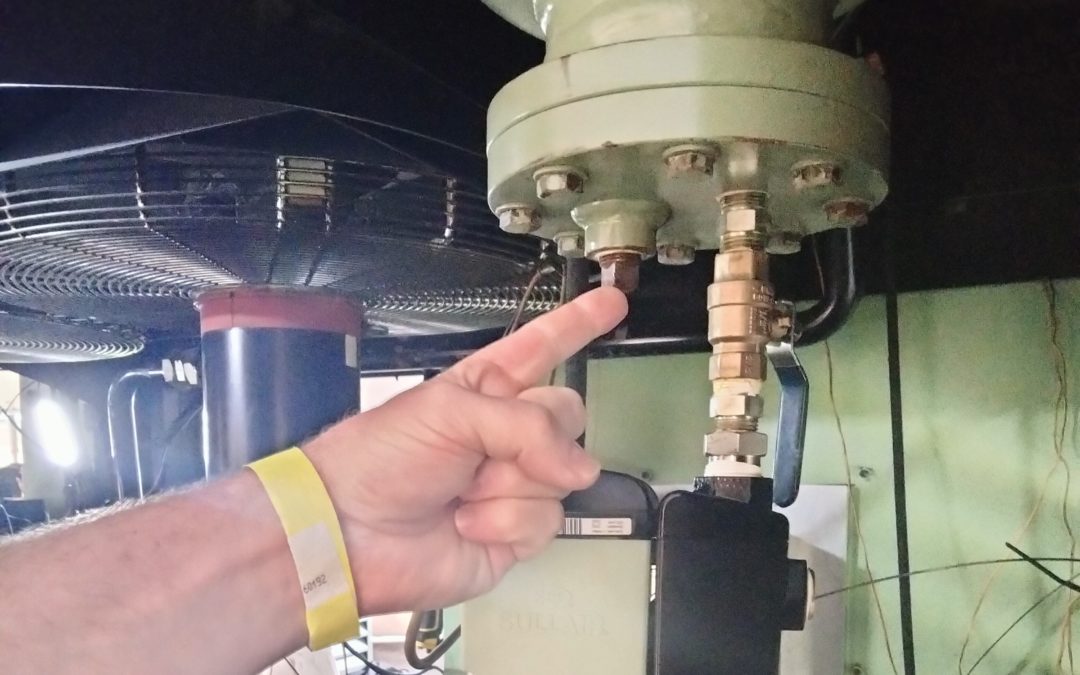

□ For Variable Speed Drives Only: Check your cooling fan & filter

One of the benefits of variable speed drives is that if the machinery is not used continuously, the compressor will be far more efficient in stopping and starting. However, this means that the cooling fan may wear down easier in the shut-off process. Now is the perfect time to make sure your cooling fan & the filter to it can beat the summer heat.

Pump Checklist

□ Check Oil/lubrication on pumps

When conducting any kind of seasonal equipment maintenance, checking oil is a vital first step. For a pump to run properly, the rotating or moving parts must be able to move freely, and the stationary parts must stay where they need to be. So, making sure that those moving parts are properly lubricated is the first thing to check on your pump.

□ Lubricate Bearings

Similarly, making sure that the joints & bearings on your pump are lubricated is also very important. However, it is even more important to make sure that your bearings are not over lubricated, as this also damages your pump. Consult your pump’s manual or user guide to know how much lubrication is needed for your bearings.

For facilities that do not want to spend the time to check the user manual for every pump and then lubricate every bearing, A.W. Chesterton offers the Lubri-cup as the perfect solution. This device automatically dispenses the preprogrammed amount of lubrication to the pump. One Lubri-cup can reduce a facilities manager’s workload by two days, which means your team can spend more time on other tasks than just lubricating pumps.

For facilities that do not want to spend the time to check the user manual for every pump and then lubricate every bearing, A.W. Chesterton offers the Lubri-cup as the perfect solution. This device automatically dispenses the preprogrammed amount of lubrication to the pump. One Lubri-cup can reduce a facilities manager’s workload by two days, which means your team can spend more time on other tasks than just lubricating pumps.

□ Check Mechanical Seals and Packing (if applicable)

The more leaks a pump has, the less efficient it will be. One of the easiest places for leaks to occur is in the seals. So, if your pump has mechanical seals to prevent leaks, check those fairly often. If there is a puddle underneath a seal, you need a new seal. The same also goes for pump packing as well.

□ Check the Coupling Element

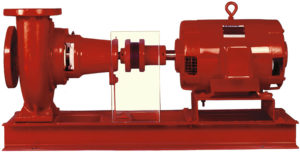

Image from Pumps & Systems

If your pump has a coupling element, it will be located between the motor & pump (see image to the right). If your motor & pump are not properly aligned, you will wear out not just the coupling element but the motor & pump as well. So, if you look at your pump and there is shredded material below your coupling element, call your pump service provider immediately.

□ Feel your pump

Our pump technicians also recommend checking your pumps at startup by placing one hand on the motor and one hand on the pump where it is safe to do so. When your pump turns on, you should feel smooth vibration. If you feel a lot of vibration or your pump is louder than usual, that means it could be experiencing cavitation or air pockets. These air pockets damage the interior of the pump, which can then lead to replacing a pump earlier than expected.

Next Steps

Download an air compressor-specific seasonal facility maintenance checklist by clicking here. Download the pump checklist by clicking here. If you need help completing this checklist, why not consider Northwest Pump’s Rotating Equipment Service Agreements. Email our service team at service@nwpump.com or call us at 1-866-577-2755 to have a customized service plan of your own.