Apr 25, 2022 | Services

Are you looking for simplicity, control, and flexibility in your POS system? Don’t look any further because the Gilbarco Passport Point-of-Sale System is just that. Investing in Passport today means investing in the POS technology of tomorrow.

With Passports touchscreen and intuitive design, Gilbarco will have your business’s employees trained within 20 minutes or less. Passport’s unmatched simplicity allows you to focus on your strategy, not your technology. Extensions within the Passport ecosystem allow you to serve and reach your customers across your entire site and entire network site.

Manage Smart. Stay Secure.

By being first to market with an outdoor EMV solution, Gilbarco has honed the EMV transition process with special features like functionality that ensures no bank card is left behind by consumers.

Passport’s easy integration with third-party systems and powerful reporting and tracking tools give you everything you need to run and manage a cutting-edge fuel retailing system. The Method of Payment Report calculates credit and debit transactions for fuel, merchandise, and car wash sales to reduce card processing fees.

Additionally, Passport provides sophisticated alerts and safeguards that help your employees perform at their best and secure your investment. It all adds up to tighter security, fewer surprises, and better results for you, your employees, and your customers.

More Partners. More Possibilities.

Gilbarco’s POS Passport has more than 120-certified partners, allowing you significant flexibility to most effectively meet your evolving needs.

Here are the partners that cover all your needs: Back Office Systems, Broadband/WAN Networking Solutions, Car Wash Controller, Electronic Loyalty Programs, Integrated Loyalty Programs, Mobile Payment Processing Networks, Proprietary Fleet / Auxiliary Network Security Camera, and Tank Gauges.

Third Party Developer Support

This portal is specifically designed to support third-party companies interested in interfacing. Gilbarco Passport point-of-sale systems and/or developing applications for use on the new Encore Experience forecourt applications solution.

Next steps

If you are interested in Gilbarco’s POS System, we currently have stock in our branches and can ship your product out today!

- MOC Pricing (call for bulk discounts)

- UPS included

Contact our POS contact, Tim!

Mar 15, 2022 | Petroleum

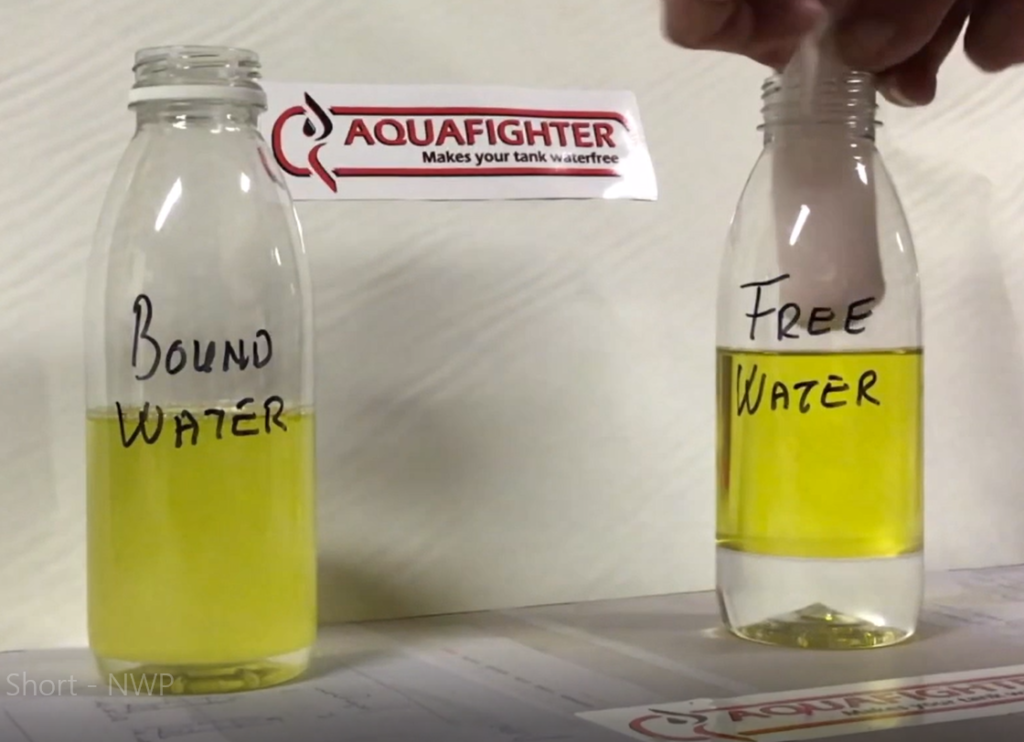

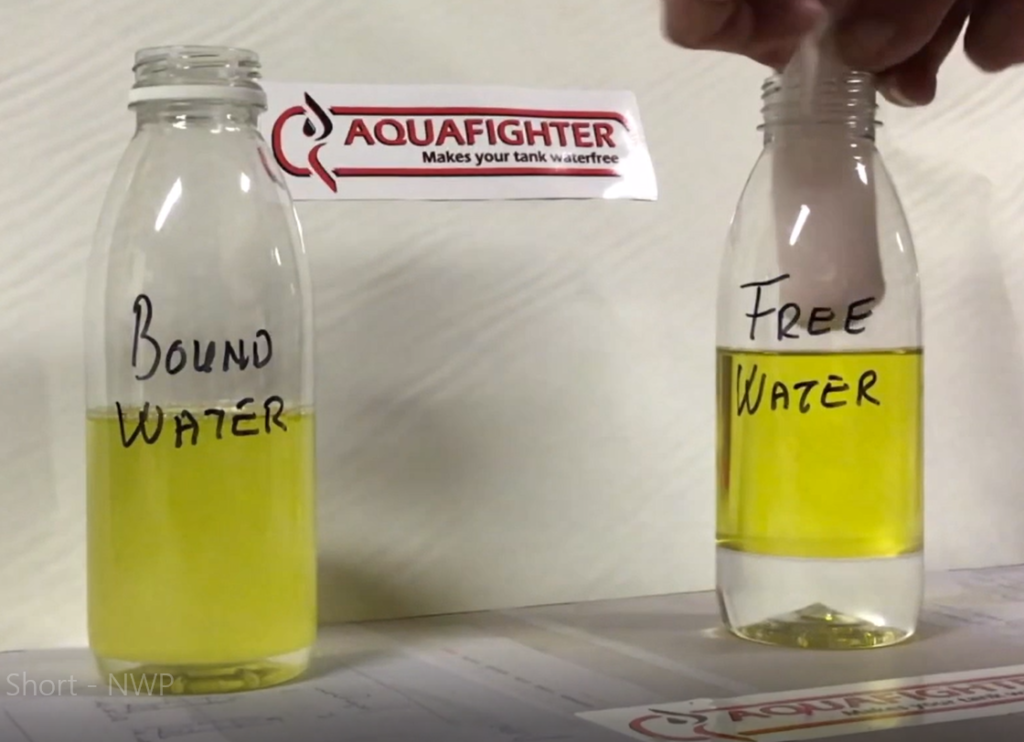

Introducing Aquafighter®, the newest and best weapon in the fight for water free diesel tanks. Water is harmful to both the storage system and to the engines that consume the fuel. Elimination of water is the best method to preserve your system and yours, or your customers, mobile equipment. Aquafighter® can help your tank in several ways:

• Ingress from atmosphere

• Free water fall-out

• Condensation in tank

• On delivery from supplier

• Leakage into tank

• Spill bucket drain ports

Developed in Norway in 2015, Aquafighter® is the first product ever to accomplish the 3 indispensable actions that are necessary to achieve complete fuel purity and tank protection at all times over time.

1. De-emulsifies and actively removes water from fuel to 65ppm with 100% efficiency. (Aquafighter® does this without chemically altering the fuel)

2. Captures all free water in the tank, and immediately captures water as soon as it causes de-emulsification.

3. Isolates water in a protective gel to permanently segregate the water from the tank environment as well as from the fuel & holds it until removal from the tank.

Don’t be mistaken, every fuel tank on Earth takes in water from the air because of humidity that is naturally in the air (No, your tank is not an exception, even if you are in the desert). Atmospheric reality leaves no exceptions. Water can also come from the fuel delivery, but even with perfect fuel deliveries water accumulates in your tank daily that contaminates your fuel, damages your equipment, corrodes your tank and grows bacteria.

What’s Next?

If you are interested in the Aquafighter product and water free diesel tanks, Northwest Pump is now a distributor in all West Coast states. Contact us via email at sales@nwpump.com or call 1-800-452-PUMP. CLICK HERE for all our branch locations.

Dec 1, 2021 | General

Northwest Pump is going into its 63rd year of business in 2022, and looking to a bright future as our current Vice President, Bob Mathews, will take over as President starting January 1st. Starting with just petroleum equipment sales, Northwest Pump has expanded immensely to now encompass Industrial equipment sales and service as well as an ecommerce option for the current customer base.

“Bob has had a tremendous career over the years. His leadership in our Industrial division, as well as our partner companies (SME and SolvOne) have been a tremendous boost to Northwest Pump as a whole. Bob will do a terrific job and provide great leadership for our Company,” Mark Mathews, Current NWP President/CEO.

Mark Mathews, current President/CEO will remain CEO until the end of 2022 to assist in the transition. Northwest Pump has been employee-owned and operated since 2006 and has remained a customer centric business since day one. New leadership comes with new pivots, but the current mission statement “customer service is our business” will always remain the same.

“I’m excited to lead the incredible team at Northwest Pump as President. NWP has been very successful over the last 62+ years. I have had the pleasure of working here for 35 of those years. We will acknowledge and build on that success as we continue to evolve as a company for future success. Following the leadership of Mark Mathews and what he has taught me and having him continue in the role of CEO, gives me confidence in my ability to handle this position, “ Bob Mathews, Current NWP Vice President.

Jul 7, 2021 | Industrial

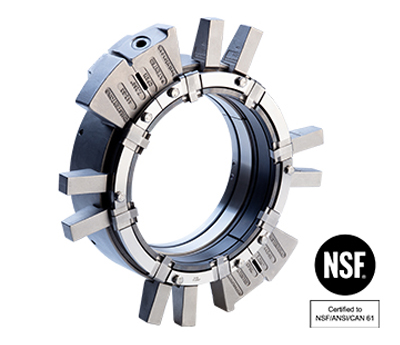

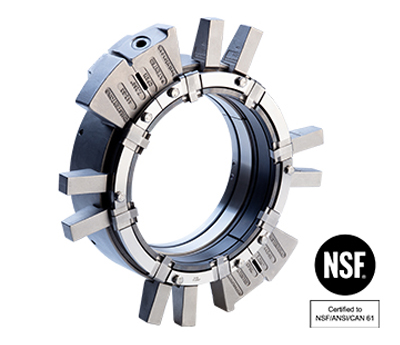

During normal operation, municipal wastewater like many plants utilizes large rotating equipment to move fluid (wastewater) throughout various processes within each treatment plant. Large equipment repair and ultimately disassembly leads to reduced equipment availability, additional labor needs, lifting & rigging, incidental component replacement, and disruption of nearby plant and services, just to mention a few challenges faced. These critical equipment disassembly costs can be dramatically reduced with the A.W. Chesterton 442C XL Cartridge Split Mechanical Seal advantages. This seal delivers ease of installation and use, without equipment disassembly. In customer terms, the A.W. Chesterton 442C XL improves reliability and reduces maintenance costs.

A.W. Chesterton 442C XL Cartridge Split Mechanical Seal design incorporates features that protect the precision lapped, split faces, incorporates an adjustable gland that makes for easy adjustment to suit your equipment bolting pattern, and does not require the pump to be disassembled to maintain. Since the pump remains assembled during the seal installation, the pump remains aligned. This is a double feature, eliminating pump disassembly time and reducing the complex startups process.

As of this blog, A.W. Chesterton is now supplying this technology in a much larger range of sizes. The latest developments have raised the bar and the range significantly to fit rotating equipment shafts from 5.00” up to 7.75”. This increases the application opportunity to reduce downtime and increases productivity.

This new size range with the 442C platform is finding success and continued proven reliability in many industries and applications. A.W. Chesterton 442C XL Cartridge Split Mechanical Seal assures the plant personnel time-savings and a reliable sealing solution. With over 10,000 Chesterton split seals installed and operating globally, you can be confident in implementing this technology.

Split seals can be installed on small and large pumps across your site. Common applications can be found in the following industries:

Power Industry

Such as River Water Intake Pumps, Water Turbines and Raw Water Pumps

Chemical Processing

Such as Cooling Water Pumps, Rotary Filter and Reactors

Water Processing

Such as White Water Pumps, Utility Water Pumps and Sewage Pumps

Learn more about the benefits of A.W. Chesterton 442C XL by contacting your local Northwest Pump branch: 800-452-PUMP or sales@nwpump.com

Jun 2, 2021 | Industrial, Services

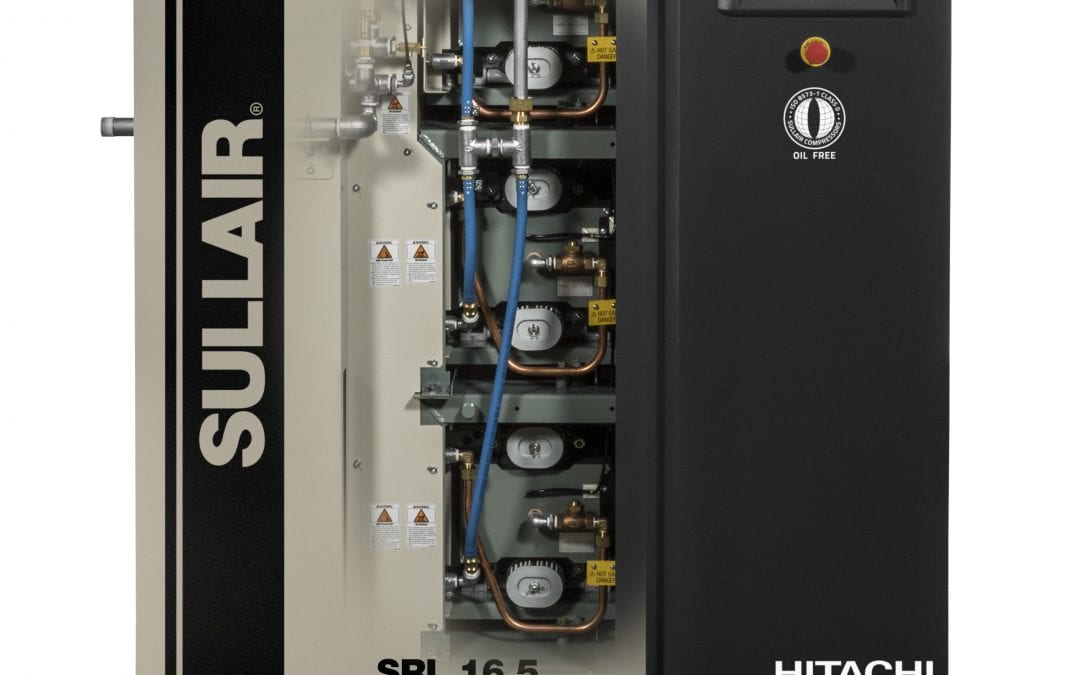

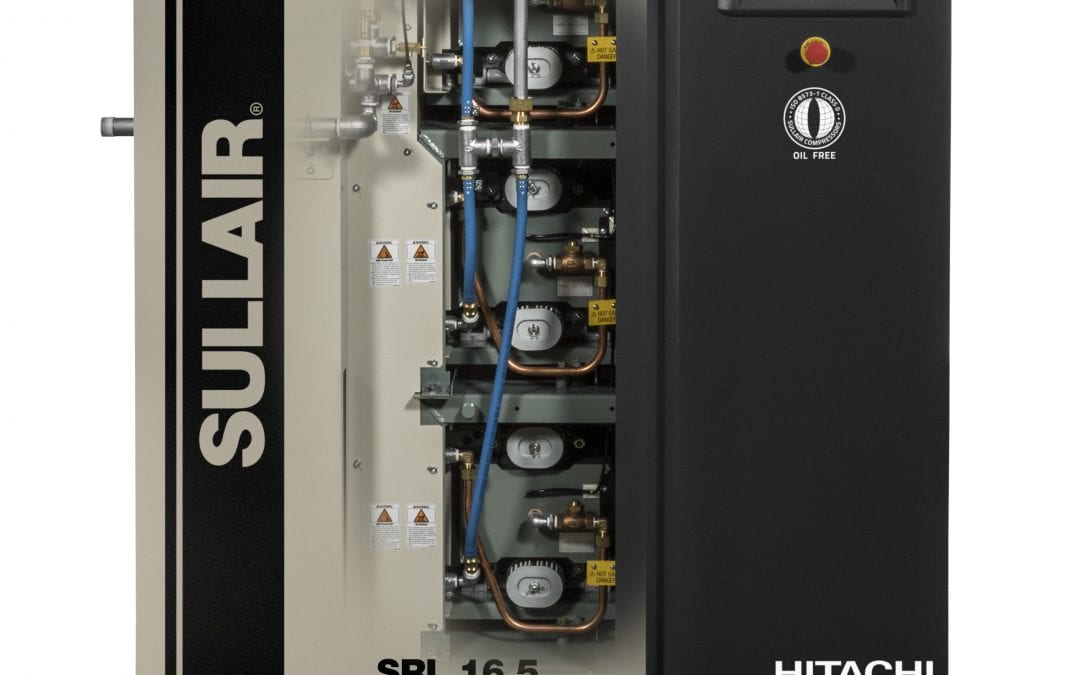

When you are in the market for ISO 8573-1 Class Zero air quality it is important to understand the difference between an “oil-free” air compressor and an “oil-less” air compressor. This is especially critical in the 30HP and under compressor market. “Oil-less” and “oil-free” are not interchangeable terms. The primary differentiator is the presence of oil in the machine and the impact that it has on air quality over time. Here is what you need to know to make the best decision regarding how to achieve your ISO 8573-1 Class Zero compressed air quality.

Rotary Screw Oil-Free Compressors – Almost without exception, an oil-free rotary screw compressor does indeed have oil in it. The oil is sealed in the gear box to provide lubrication to the gears and bearings, but is sealed from the air chamber in order to prevent it from getting into the compressed air stream. As the units age, the seals do harden and wear out due to heat and shelf life. Therefore, as they age, oil will migrate into the air stream and negatively impact air quality. As this happens, air end “slippage” increases and inter-stage temperatures will creep up. Most people do not discover that their air quality has been compromised until the compressor reaches cessation on a high inter-stage temperature shutdown. By then, many pints, quarts or even gallons of oil may have migrated into the process air and piping. Also, most oil free screw compressors (with the exception of the Sullair DSP) have a vented gear box that exasperates oil laden vent air into the compressor, right near the intake filter. The vent on the gearbox adds oil vapors, which are almost immediately sucked back into the air filter and introduced to the air stream. So they are “oil-free” because they do not have oil in the air stream by design. But they are not truly an oil less solution. Mitigation of air contamination, oil maintenance and disposal, and oil leakage containment all must still be considered when applying an oil free rotary screw compressor technology.

Reciprocating Oil-Free Compressors

Reciprocating compressor designs are sold in either oil less or oil free up to about 50HP. They can also be configured into duplex, triplex or quadraplex packages to get up to cover air demands up to about 450 CFM. “Oil-free” compressors in the reciprocating market, like the screw market, do actually have oil in them. They use an extended connecting rod in an extra-tall block known as a “distance piece”. This configuration lengthens the distance between the oil sump and the compression chamber. They usually include extra oil rings as well to help prevent the oil in the crank case from migrating into the air stream. However, over time; oil and compression rings wear out in a reciprocating compressor just like they do in a car engine. So over time, oil will begin to migrate past the rings and into the compression chamber and eventually into the air stream. Most oil free compressor users do not discover their oil contamination problem until they notice a drop in system air pressure related to worn out rings. So once again, the oil free technology still comes at the cost of air and piping contamination, oil maintenance and disposal, and oil leak containment.

Oil-less Reciprocating Compressors

The true oil-less reciprocating compressors, like our Champion V & W, or the MTO II series air compressors have no oil in the crank case at all. They are a 100% true oil-less design and come in simplex, duplex, triplex or quadraplex packages including NFPA 99 compliant packages for hospital grade air. This technology is far more costly, but it provides the true outcome that the customer is aiming for: ISO 8753 Class 0 air quality, and reduced maintenance associated with lubrication systems.

Oil-Free Scroll Compressors

Scroll compressors, like our Sullair model SRL, should really be called oil-less to distinguish them from the oil-free style compressors mentioned above. Like the oil-less reciprocating, the oil less scroll compressors contain no oil at all. They are built on a platform of low maintenance intervals, and guaranteed air quality for life.

If a customer has a critical need for truly Class 0, oil free air quality, they should strongly consider using either an oil less technology like the Sullair SRL scroll package or Champion V & W series. These technologies are admittedly limited to the 100HP and below Class 0 oil free market place. So in the event that an “oil free” solution like the Sullair DSP must be used, or is already in place; customers should consider installing early detection of oil content to prevent piping and process contamination. Air quality monitoring systems like our Beko Metpoint OCV will ensure that they maintain air quality that is in compliance with ISO 8573 for oil free quality air.

Looking to switch over to oil-free or oil-less air compressors? Northwest Pump sells air compressors in the Seattle and Washington regions, Oregon, Idaho and Montana. Reach out to Northwest Pump today – sales@nwpump.com or call 1-800-452-PUMP.