What Sets a Wilden AODD Pump Apart

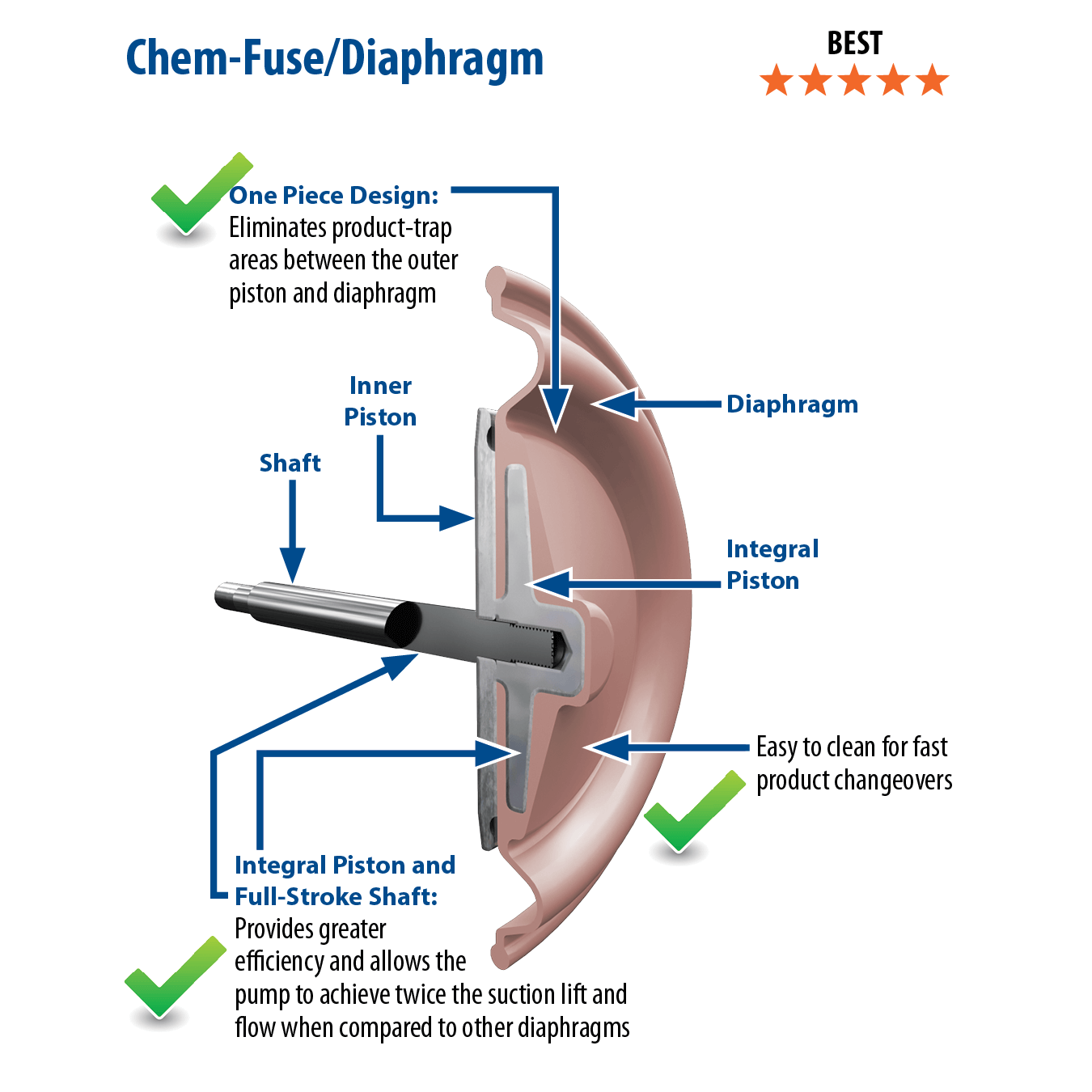

Two unique attributes set these air-operated double-diaphragm pumps apart from others on the market. These are the air distribution system (ADS) and the diaphragms. The ADS behind each series of Wilden pumps only uses three moving parts. The simplistic design than reduces the need for unnecessary downtime and lengthens uptime periods. Wilden designs its chem-fuse diaphragms with the piston’s metal underneath the diaphragm’s plastic. This eliminates trap areas that the fluids are often trapped in and makes them easier to clean.

How AODD Pumps Work

Wilden AODD Pump Series

- Pro-Flo Series

- Pro-Flo Shift Series

- Turbo-Flo Series

- Accu-Flo Series

- Saniflo Series

- High-Pressure Series

- Stallion Series

- Brahma Series

- GPS Series

- UL Series

- Velocity Series

The Pro-Flo pump from Wilden is unique because of its Air Distribution System (ADS), which allows the diaphragms to move without priming. The simple design of the Pro-Flo pumps reduces the risks of leaks by eliminating the need for mechanical seals and maximizes the length of time between downtime periods.

The Pro-Flo pump from Wilden is unique because of its Air Distribution System (ADS), which allows the diaphragms to move without priming. The simple design of the Pro-Flo pumps reduces the risks of leaks by eliminating the need for mechanical seals and maximizes the length of time between downtime periods.

Industry Applications:

- Energy Production

- Process & Manufacturing

- Food & Beverage

- Mining

- Water & Wastewater

Configurations:

Bolted Pumps can be made with:

- Sizes varying from 1/4″ to 3″

- Metal

- Aluminum

- Ductile Iron

- Stainless Steel

- Alloy C

- Plastic

- Polypropylene

- PVDF

Clamped Pumps can be made with:

- Sizes varying from 1/4″ to 2″

- Metal

- Aluminum

- Ductile Iron

- Stainless Steel

- Plastic

- Polypropylene

- PVDF

Wilden’s Pro-Flo SHIFT series takes all the benefits of the Pro-Flo series and adds increased energy savings and higher flow rates. This lengthens the lifespan of the pump as well as lowers the cost of maintenance over the course of its lifetime.

Wilden’s Pro-Flo SHIFT series takes all the benefits of the Pro-Flo series and adds increased energy savings and higher flow rates. This lengthens the lifespan of the pump as well as lowers the cost of maintenance over the course of its lifetime.

Industry Applications:

- Energy Production

- Process & Manufacturing

- Food & Beverage

- Mining

- Water & Waste Water

Configurations:

Bolted Pumps can be made with:

- Sizes varying from 1/4″ to 3″

- Metal

- Aluminum

- Ductile Iron

- Stainless Steel

- Alloy C

- Plastic

- Polypropylene

- PVDF

Clamped Pumps can be made with:

- Sizes varying from 1/4″ to 2″

- Metal

- Aluminum

- Ductile Iron

- Stainless Steel

- Plastic

- Polypropylene

- PVDF

The Turbo-flo is Wilden’s specialized series for utility uses. Wilden designs these pumps to be easy-to-maintain & economical solutions for de-watering needs.

The Turbo-flo is Wilden’s specialized series for utility uses. Wilden designs these pumps to be easy-to-maintain & economical solutions for de-watering needs.

Industry Applications:

- Marine Transportation

- Mining

Configurations:

- Sizes offered in:

- ½”

- 1½”

- 2″

- 3″

- 4″

- Aluminum wetted-housing only

The Accu-Flo pump series from Wilden is best suited for precise control applications. Its Air Distribution System (ADS) uses a two-positioned, four-way solenoid valve instead of the standard plug. These solenoids allow for better control & optimization of flow.

The Accu-Flo pump series from Wilden is best suited for precise control applications. Its Air Distribution System (ADS) uses a two-positioned, four-way solenoid valve instead of the standard plug. These solenoids allow for better control & optimization of flow.

Industry Applications:

- Chemical Processing

- General Industrial Manufacturing

Configurations:

- Sizes offered:

- 1/8″

- 1″

- 2″

- Bolted pumps offered in metal or plastic

- Clamped Pumps only offered in plastic

The Saniflo series from Wilden is actually divided into two: hygienic & FDA. Saniflo Hygienic series has a clean-in-place capability as well as reduces potentially contaminating residues. It is best suited for low-acid, protein-based, and pasteurized products. Saniflo FDA is best suited for high high-acid, high-sugar, & high-fat products.

The Saniflo series from Wilden is actually divided into two: hygienic & FDA. Saniflo Hygienic series has a clean-in-place capability as well as reduces potentially contaminating residues. It is best suited for low-acid, protein-based, and pasteurized products. Saniflo FDA is best suited for high high-acid, high-sugar, & high-fat products.

Certifications:

Hygenic:

- 3A

- ATEX

- EC 1935/2004

- FDA CFR 21.177

FDA:

- FDA

- CE

- EC 1935/2004

- ATEX requirements

Industry Applications:

- Food & Beverage

- Pharmaceuticals

- Chemical Applications

- Cosmetics

Configurations:

- Both Saniflo series Pumps offered only in stainless steel

- Sizes offered for Saniflo FDA:

- ½”

- 1½”

- 2″

- 3″

- Sizes offered for Saniflo Hygenic:

- 1″

- 1½”

- 2″

- 3″

The High-Pressure series from Wilden uses its unique Air Distribution System (ADS) to reliably deliver up to 20.7 bar (or 300psig) of pumping power. This is possible by utilizing a double-acting power piston & duplex technology to strengthen pressure within the pump.

The High-Pressure series from Wilden uses its unique Air Distribution System (ADS) to reliably deliver up to 20.7 bar (or 300psig) of pumping power. This is possible by utilizing a double-acting power piston & duplex technology to strengthen pressure within the pump.

Industry Applications:

- Chemical Processing

- Water & Wastewater

- Food & Beverage

- General Industrial Processing

Configurations:

- Sizes offered:

- 1″

- 1½”

- 2″

- 3″

- Only offered in metals:

- Aluminum

- Stainless Steel

- Ductile Iron

- Alloy C

Look no further than Wilden’s Stallion series pumps for rugged mining operations and their slurries. Its large internal clearance controls clogging even while dealing with thick slurries produced by mining. These pumps also contain a screen base to act as a filter against the solids that would cause damage.

Look no further than Wilden’s Stallion series pumps for rugged mining operations and their slurries. Its large internal clearance controls clogging even while dealing with thick slurries produced by mining. These pumps also contain a screen base to act as a filter against the solids that would cause damage.

Industry Applications:

- Mining

- Water & Wastewater

- General Industrial Processing

Configurations:

- Sizes offered:

- 1½”

- 2″

- 3″

- Stallion Pumps only made with metal materials

- Aluminum

- Ductile Iron

- Cast Iron

- Not offered as a bolted pump

Wilden’s Brahma series pump is specifically designed to safely transport solid-laden slurries as effectively as possible because of its top inlet & bottom discharge. The Brahma series uses either the Pro-Flo Shift or Turbo-Flo Air Distribution System (ADS).

Wilden’s Brahma series pump is specifically designed to safely transport solid-laden slurries as effectively as possible because of its top inlet & bottom discharge. The Brahma series uses either the Pro-Flo Shift or Turbo-Flo Air Distribution System (ADS).

Industry Applications:

- Water & Wastewater

- General Industrial Processing

- Mining

Configurations:

- Offered in either 2″ or 3″

- Only offered as bolted pumps in these metals

- Aluminum

- Ductile Iron

The GPS series pump from Wilden uses the Air Distribution System (ADS) from the Pro-Flo Shift to optimize the usage of Natural Gas where facilities lack compressed air.

The GPS series pump from Wilden uses the Air Distribution System (ADS) from the Pro-Flo Shift to optimize the usage of Natural Gas where facilities lack compressed air.

Industry Applications:

- Oil & Gas

- Chemical Processing

- General Industrial Processing

Configurations:

- Sizes offered:

- ½”

- 1″

- 1½”

- 2″

- 3″

- Offered as clamped & bolted pumps

- Metals offered:

- Aluminum

- Stainless Steel

Wilden offers the UL series pumps for facilities that specifically require certification to UL 79 standards. These pumps can be used to pump gas products, fuels, petroleum, or other lubricating applications.

Wilden offers the UL series pumps for facilities that specifically require certification to UL 79 standards. These pumps can be used to pump gas products, fuels, petroleum, or other lubricating applications.

Industry Applications:

- Oil & Gas

- Petroleum

Configurations:

- Sizes offered

- ½”

- 1″

- Offered as clamped & bolted aluminum pumps

The Velocity series pump from Wilden offers smaller sized pumps without compromising the needed pumping capabilities. These pumps can be installed in several configurations in special mounts to maximize the space these pumps operate in without crowding.

The Velocity series pump from Wilden offers smaller sized pumps without compromising the needed pumping capabilities. These pumps can be installed in several configurations in special mounts to maximize the space these pumps operate in without crowding.

Industry Applications:

- General Industrial Processing

- Oil & Gas

- Power Generation

Configurations:

- Sizes offered:

- ¼”

- ½”

- Only offered as bolted plastic pumps

Bolted Pumps

Clamped Pumps

Plastic vs. Metal Pumps

When determining what kind of materials for your pump, we will need to know what it will pump and at what temperature.

Wilden Parts Available through Northwest Pump

Surge Dampeners

A common problem with AODD pumps is water hammer, the same rhythmic bursts of force that push the fluid out of the pump can also prematurely damage other downstream equipment. This process can also mean that downstream piping vibrates more, which can weaken joints and cause premature failure. To avoid this problem altogether, AODD pump manufacturers offer surge dampeners. These dampeners work by absorbing this rhythmic shocks before they can impact piping or other equipment.

Wilden offers its surge dampeners in four sizes, 1″, 1½”, 2″, & now in 3″.

Next Steps

Interested in a Wilden AODD Pump for your pumping solution? Reach out to our sales team at sales@nwpump.com for more information, or call us at 1-800-452-PUMP.

If you need help with installation, maintenance, or a 24-hour emergency repair service, please reach out to our services team by calling 1-866-577-2755 or submit an inquiry, and we can get an appointment scheduled for you.