One of the many ways a facility can become more environmentally friendly is changing how they receive its compressed air. Using the wrong compressor can mean less efficient production and more energy waste. On the other hand, improperly running the right air compressor can also waste energy. Here are a few ways to make your facility a little more green with Sullair.

Air Compressor Longevity

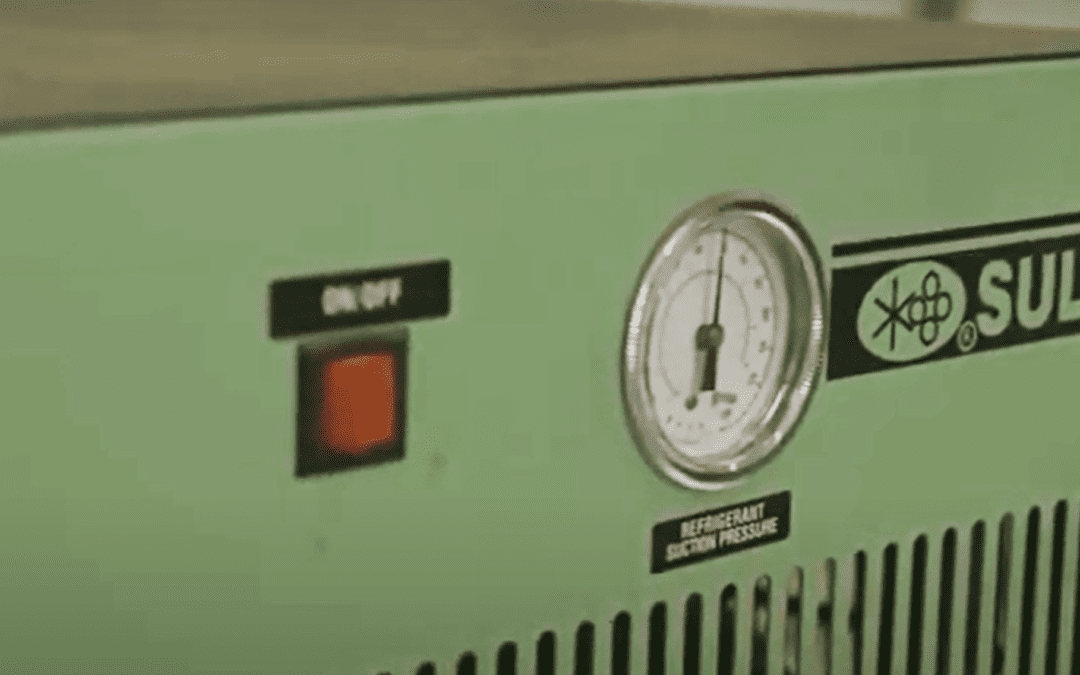

Since 1965, Sullair has been known for durable air compressors. Driven by a legendary air end design, Sullair builds its compressors to last. A Sullair unit can reliably run more than seventy-thousand hours before needing to be replaced. To put this into perspective: a typical 40-hour workweek means an average of 2,080 hours in a year. With the right maintenance, lubrication, and compressed air system in place, a compressor from Sullair can last even over one hundred thousand hours.

Sullair’s Sustainable Equipment Offerings

The two best Sullair air compressor series for being environmentally friendly are the S-Energy and the DSP series. Both compressors have Variable Speed Drives (also referred to as VDS). This allows the compressor to control the motor’s speed at many different levels instead of one precise point, which can increase the energy efficiency of the air compressor in the right circumstances. This means you only pay to compress the air you need, which helps increase energy efficiency and saves you money. Those interested in VDS compressors but do not have enough need for it can also consider having a spiral valve on their compressor.

The DSP Series

The DSP series is oil-free, meaning that the oil does not encounter the air being compressed. In fact, the DSP series has ISO 8573-1 Class Zero air, which means that this air surpasses Class 1 qualifications- all without needing as much additional filtration equipment as oil flooded compressors. This eliminates the chance of oil damaging sensitive machinery through the air and makes the condensate byproduct safer for disposal. When air purity is critical, the DSP series is a great choice.

The DSP series is oil-free, meaning that the oil does not encounter the air being compressed. In fact, the DSP series has ISO 8573-1 Class Zero air, which means that this air surpasses Class 1 qualifications- all without needing as much additional filtration equipment as oil flooded compressors. This eliminates the chance of oil damaging sensitive machinery through the air and makes the condensate byproduct safer for disposal. When air purity is critical, the DSP series is a great choice.

All DSP compressors come with an oil-demister, which further retains the oil used to make it even more efficient. Another feature the DSP series offers is the patented high pre-cooler design. This prevents premature after-cooler failure and increases the durability of the compressor further. Another feature of the DSP series compressor is the optimized rotor design. Typically, oil-free compressors use PTFE. However, with proprietary MOS2 coating, Sullair maximizes the lifespan of the air-end and protects your investment. Finally, a standard DSP series compressor has a totally enclosed, fan-cooled (TEFC) motor and an optional NEMA 4 Wye-Delta starting cabinet. The TEFC motor means that outside contaminants do not enter the machine, which prevents long-term damage, and the NEMA 4 starting cabinet further protects against dust & harsh weather.

The S-Energy Series

While the S-Energy compressor series is oil-flooded, meaning that oil mixes with compressed air and the condensate, there are ways to minimize harm to the environment and increase efficiency. Sullair S-energy compressors are engineered for reliability, durability, and performance. These units can help you optimize efficiency and are in for the long haul. They can last up to 100,000 working hours if you treat them right.

While the S-Energy compressor series is oil-flooded, meaning that oil mixes with compressed air and the condensate, there are ways to minimize harm to the environment and increase efficiency. Sullair S-energy compressors are engineered for reliability, durability, and performance. These units can help you optimize efficiency and are in for the long haul. They can last up to 100,000 working hours if you treat them right.

S-Energy units come standard with a TEFC motor & NEMA 4 Wye-Delta starting cabinet, just like the DSP. Additionally, Sullair used their fifty-five years of experience designing lasting air-ends to maximize the lifespan of the S-Energy compressors. An S-Energy unit can easily last for seventy, eighty, or even one hundred thousand working hours with the correct maintenance. The last standard S-Energy sustainability feature is the WS control system. Its enhanced functionality means that an operator can receive energy usage reports on their computer, tablet, or smartphone and better control the outputs of their compressor.

Sustainable Air Compressor Attachments

Sullair offers many auxiliary products to help keep your operation environmentally friendly. Northwest Pump recommends the following products to help optimize energy efficiency and improve the longevity of your compressor and its components and other equipment and products.  First, help separate harmful oil from condensate by using an oil/water separator. This keeps the condensate safe for drains, pipes, and accidental spills and allows for safer oil disposal.

First, help separate harmful oil from condensate by using an oil/water separator. This keeps the condensate safe for drains, pipes, and accidental spills and allows for safer oil disposal.

The following sustainable attachment is the SULLIMAX Condensate Drain. It works using an automatic drain to remove condensate at a specific temperature without releasing compressed air. This reduces compressor maintenance and reduces energy use, and maximizes savings. According to Sullair’s trials, a facility could see a return on investment for the SULLIMAX in 150 days.

Finally, every compressor needs fluid or oil to keep it running, and Sullube is one of the top compressor fluids on the market. It protects the Diamond warranty on the S-Energy series and is also biodegradable. This means that handling or disposing of condensate with Sullube is faster, safer, & cheaper. Another feature of Sullube is that it is non-varnishing and cleans existing varnish off surfaces.

What Northwest Pump does to keep your equipment sustainable

Northwest Pump has a few tricks up our sleeve to lower your carbon footprint as much as possible. Our technicians and representatives offer site & utility assessments for new projects. These audits can determine how much a facility will spend on utilities & how to minimize pain points in the production flow. From there, we can offer customizable solutions to serve the needs of our customers best. Additionally, our service team provides customizable rotating equipment service plans. These plans mean our service technicians arrive at your facility and maintain your air compressors and pumps. Our service team also offers recycling services for air compressor filters & oil.

Next Steps

Looking for your sustainable equipment solution? Start the conversation by emailing us at sales@nwpump.com or calling 1-800-452-PUMP. Interested in our service capabilities? Reach out here for service requests or call 1-866-577-2755.