Industrial Products

Northwest Pump is a market leader in Industrial Products, factory-trained service, and custom fabrication for a wide range of equipment from some of the top brands in the industry. From municipal operations or manufacturing facilities to food production, and more; count on us to have the experience and knowledge you need to make your processes flow.

We are a supplier of high-quality industrial products and brands for your project needs. View our top recommended products by product category or view a complete list of our vendors here. Northwest Pump is proud to carry products from renowned brands such as:

As always, if you have any questions or need a personalized recommendation on our Industrial Products and Brands, be sure to contact us at any time – our industrial product experts are here to help.

Available Product Categories

Metering & Mixing EquipmentView Details

Metering & Mixing EquipmentView Details Heavy Duty Industrial Air CompressorView Details

Heavy Duty Industrial Air CompressorView Details Industrial Centrifugal PumpsView Details

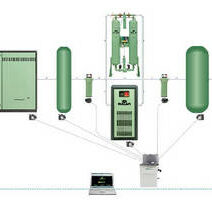

Industrial Centrifugal PumpsView Details Industrial Air Compressor Engineered PackagesView Details

Industrial Air Compressor Engineered PackagesView Details Compressed Air TreatmentView Details

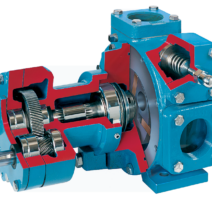

Compressed Air TreatmentView Details Positive Displacement PumpsView Details

Positive Displacement PumpsView Details Industrial Vacuum PumpsView Details

Industrial Vacuum PumpsView Details Industrial Gas CompressorsView Details

Industrial Gas CompressorsView Details Compressed Air Piping SystemsView Details

Compressed Air Piping SystemsView Details Industrial Submersible PumpsView Details

Industrial Submersible PumpsView Details Industrial Nitrogen GeneratorsView Details

Industrial Nitrogen GeneratorsView Details Electric Motors, Drives, & ComponentsView Details

Electric Motors, Drives, & ComponentsView Details Fire Safety PumpsView Details

Fire Safety PumpsView Details Industrial Parts & AccessoriesView Details

Industrial Parts & AccessoriesView Details Industrial Slurry PumpsView Details

Industrial Slurry PumpsView Details

Check out our Favorite Industrial Product Brands

Brands We Carry

Reliability. Durability. Performance.

Since 1965, Sullair has been on the leading edge of compressed air solutions. We were one of the first to execute rotary screw technology in our air compressors, and our machines are famous throughout the world for their legendary durability. As the industry moves forward, we will remain at the forefront with quality people, innovation, and air compressors that are built to last.

Utilizing the most modern technologies, equipment and advanced manufacturing techniques, Sullair designs, manufactures, assembles, and tests the most innovative compressed air and vacuum products in the industry. Sullair products are known around the world for their universally applicable design, outstanding craftsmanship and superior quality.

Sullair specializes in Industrial Air Compressors, Rotary Screw Air Compressors, Oil Free Air Compressors, Scroll Compressors and Accessories.

Productive, Pure, and Profitable

In 1966, five men intent on manufacturing high-altitude balloons founded a company in suburban St. Paul, Minnesota, that they called Pentair, the Greek “penta” for the five founders and “air” for the products they planned to produce. Pentair diversified quickly venturing into a wide variety of industries and eventually focusing its portfolio on water treatment and sustainable applications. This includes acquisitions of great brands, some of which have been serving customers for 150 years. Pentair is the parent company to Aurora Pumps and Fairbanks Nijhuis Pumps

Plant profitability is generally driven by operational efficiency, continuous operation, and quality. Pentair helps to improve your results for all three areas with a full range of fluid-management solutions, including sampling systems that allow for in-process quality testing, helping ensure both production consistency and final product integrity.

Pentair specializes in Centrifugal Pumps, Plunger Pumps, Booster Pumps and Vertical Turbine and In Line Pumps.

Delivering Tomorrow’s Innovative Fluid and Material Transfer Solutions Today

PSG® is the global pump solution expert, enabling safe and efficient transfer of critical and valuable fluids and materials that require optimal performance and peace of mind reliability in applications where it matters most. We feature world-class pump brands such as Abaque®, All-Flo®, Almatec®, Blackmer®, Griswold®, Mouvex®, Neptune®, and Wilden® – committed to providing the market expertise you need by delivering innovative technologies that will positively impact the world within key vertical markets, including hygienic, chemical, energy and more.

Abaque® specializes in peristaltic hose pumps for sanitary & hygienic applications.

All-Flo® offers air-operated double-diaphragm pumps for applications varying from food & beverage to mining & dewatering.

Almatec® focuses on AODD pumps for chemical & hygienic applications specifically.

Blackmer® is the leading global provider of innovative, high-quality sliding vane, centrifugal, screw and regenerative turbine pumps, and reciprocating gas compressor technologies for the safe transfer of liquids and gases.

Griswold® provides solutions for many of the world’s largest industrial applications. With their world-class engineering expertise, deep application knowledge, testing capabilities, and exceptional customer support, they meet their customers’ most demanding application requirements. Backed by 70 years of experience and commitment to manufacturing quality centrifugal pumps, Griswold™ provides solutions for many of the world’s largest chemical, oil & gas, power generation, water parks, zoos, aquariums, and fountain companies. Located in Grand Terrace, CA, USA, Griswold is a product brand of PSG, a Dover company.

Mouvex® specializes in eccentric disc pumps. These pumps were originally invented in french wine country, and continue to be a top choice for the Wine Industry.

Neptune® manufactures pumps designed for water treatment & agriculture. Neptune offers metering pumps, mixers, & other wastewater solutions.

Wilden® is a world-renowned air-operated double diaphragm pump brand. This brand offers a pump for any and every application.

PSG specializes in Air-Operated Double-Diaphragm Pumps, Rotary & Sliding Vane Pumps, Gear Pumps, and Centrifugal Pumps.

Optimizing Pump Selection and Performance to Lower Your Operating Costs

Metso Outotec was created through the combination of Metso Minerals and Outotec on June 30, 2020. They are a frontrunner in sustainable technologies, end-to-end solutions and services for the minerals processing, aggregates and metals refining industries globally.

- Robust construction and design to maximize wear life

- Modular impellor and hydraulic system design for full life cycle efficiency optimization

- Innovative design reduces cost and stress of pump maintenance and service

- Multiple shaft and seal options for every application

- Intelligent impellor design

- Long-lasting bearing and wet end design

Metso:Outotec specializes in Horizontal and Vertical Slurry Pump.

Be responsible. Think ahead. Innovate.

A global leader in advanced pump solutions and water technology, Grundfos contributes to global sustainability by pioneering technologies that improve quality of life for people and care for the planet. Grundfos’ mission is to develop and produce high-quality pumps and pumping systems, contributing to a better quality of life and a healthy environment.

PACO Pump has been designing, manufacturing, and distributing high quality pump products since 1907. PACO Pumps provides a wide range of products, with a vast array of models, sizes, and hydraulic lines to best suit your pumping application. The PACO line of pumps are one of the world’s finest and most complete lines of centrifugal pumps and pumping systems and is manufactured and marketed by Grundfos CBS Inc.

When you specify Gorman-Rupp, you benefit from worldwide service centers, knowledgeable engineers and a selection of nearly 3,000 pumps. Gorman-Rupp has been manufacturing pumps and pumping systems since 1933. Many of the innovations introduced by Gorman-Rupp have become industry standards.

Pump models offered by Gorman-Rupp include self-priming centrifugal, standard centrifugal, submersible, rotary gear and diaphragm pumps. Gorman-Rupp has over one million square feet of the most modern manufacturing and warehousing facilities found throughout the world. Providing pumps and pumping systems to customers around the globe, we never lose sight of the original philosophy that started our company: INNOVATION, IMPROVEMENT AND SUPERIOR PRODUCTS.

Fybroc® is the world leader in the design and manufacture of fiberglass reinforced pumps. These pumps are available in different materials to provide excellent corrosion resistance for tough applications including pumping of acids, brines, caustics, bleaches, solvents, seawater and a wide range of waste liquids.

Fybroc specializes in Horizontal ANSI and Close-Coupled Pumps, ISO Standard Pumps and Self Priming Pumps.

Gusher Pumps, manufacturer of Rumaco®, Ruthman, and Gusher® pumps, represents one of the largest selection of centrifugal pumps available from a single manufacturer. Models include close-coupled pumps, end suction pumps, immersed pumps, self-priming pumps, vortex pumps, sludge pumps, multi-stage pumps, full cantilever pumps. Many in vertical or horizontal styles. Ideally suited for small and large flow rates, and our multi-stage pump is capable of heads in excess of 800 ft. We also offer a range of diaphragm pumps, and turbine pumps.

The Gardner Denver Industrials Group is one of the oldest, leading providers of air compression and vacuum products. From modest beginnings as a small business located in the heartland of the United States, they have grown into a diversified corporation operating around the world.

Gardner Denver covers:

- Aerospace

- Agriculture

- Aquaculture

- Automotive

- Electronics

- Environmental

- Fluid Transfer

- Food and Beverage

- General Manufacturing

- Glass

- Iron and Steel

- Laboratory Automation

- Laboratory Testing Equipment

- Marine

- Medical

- Mining and Construction

- Oil and Gas

- Packaging

- Paper and Printing

- Petrochemical

- Pharmaceuticals

- Power Generation

- Textiles

- Transportation

- Wastewater

- Woodworking

Gardner Denver is parent company to MP Pumps, Oberdorfer and Champion

MP Pumps and Oberdorfer offer self-priming centrifugal pumps, fuel transfer pumps and booster pumps.

A.W. Chesterton Company operates in over 110 countries around the world and is recognized as a leading sealing solutions provider for rotating, stationary, and fluid power equipment reliability and efficiency. Their sealing solutions are supported by a comprehensive line of protective industrial coatings, high performance industrial lubricants, and advanced MRO products designed to extend equipment life and improve productivity.

BEKO TECHNOLOGIES develops, manufactures, and sells components and systems worldwide delivering optimized compressed air quality across an array of applications. With an industry-leading product portfolio, the company stands for compressed air and gas technology at its very best. For more than three decades, their company has developed, manufactured and sold high-quality, reliable, and efficient components and systems for compressed air treatment, processing, and condensate handling and treatment. They offer a complete program and suite of solutions that not only safeguard the stringent quality requirements of our customers’ production processes, but also achieve greater energy efficiency and, in turn, cost savings and added value. Expert advice and highly qualified service are a hallmark of this independent and family-owned company.

Dean Pump® is recognized worldwide for high quality industrial process pumps. These pumps are manufactured in a variety of metals to handle a broad range of high temperature and chemical process applications.

Liquid Controls is the global market leader in precision measuring systems providing highly engineered and differentiated products used in custody transfer of highly valuable refined fuels and liquids. From its start in 1956, Liquid Controls has been dedicated to providing high-quality flow meters and accessories for accurate liquid measurement in custody transfer applications. Beginning from the original military aircraft fueling requirement, they now serve a wide variety of applications and markets.

Their manufacturing team is made of the most highly skilled craftspeople in the region, all working together each day to assure that personal care goes into each task that makes up an LC product. They rely on a strong combination of in-house engineered designs and a network of strategically located factory authorized full-service distributors to ensure that their customers around the world are supported with technology tailored to each industry’s particular requirements.

Atlas Copco is a Swedish multinational industrial company that was founded in 1873. Atlas Copco USA provides compressed air and vacuum equipment, industrial power tools, and construction equipment.

Atlas Copco in the United States handles the sales and service of industrial gas and air compressors, dryers and filters, compressor parts and service, and vacuum pumps; construction including mobile compressors, pumps, light towers and generators, handheld tools, Industrial electric, pneumatic, cordless transducerized assembly tools, alongside an extensive range of pneumatic grinders, sanders, chipping hammers and riveting systems.

AMT Pump Company is A Subsidiary of The Gorman-Rupp Company located in Mansfield, Ohio. AMT offers over 1000+ different standard model numbers of which 400+ are readily available and offered as QSP, Quick Ship Products. AMT manufactures and sells Industrial / Commercial pumps & accessories through authorized distributors.

For over 85 years, Hannay Reels has been committed to solving their customers’ issues. While their story is ever-evolving, this philosophy remains the same – and it’s what has helped them grow into a strong global business and the #1 reel manufacturer.

Our goal is to provide the world with the most durable and well-engineered reels in the industry, and to deliver them with the friendly, knowledgeable service that their customers have come to expect. They have an unwavering commitment to listen to the needs of their customers and respond by crafting high-quality products that perform safely, efficiently, and economically.

Wondering how we work? Check out our case studies for an overview of projects we have completed from start to finish.

View our photo gallery of past and present projects by Northwest Pump, covering a wide range of products and equipment.

Vendor Testimonial

Northwest Pump’s staff make business great because they are very well educated in the industry. ~Liquid Controls

Customer service is our business.

Serving the petroleum and industrial industry for over 65 years.

How can we help?

Our petroleum and industrial staff are here to assist and well- versed in product knowledge and installation protocol. Let us take it from here. For 24-hour assistance, call 1-866-577-2755!