Mar 1, 2021 | Industrial

Northwest Pump has been a supplier in Washington, Oregon and Alaska for Metso Outotec’s Slurry Pumps, Cyclone Separation, Slurry Valves & Slurry Piping and Hose Systems for nearly 20 years. Now we are prepared to supply Montana. Metso Outotec’s pumps are a frontrunner in sustainable technologies, end-to-end solutions and services for the minerals processing, aggregates and metals refining industries globally. Northwest Pump is excited to expand our Metso-Outotec’s slurry pumps along the Western Plains.

Metso Outotec’s Orion Series horizontal slurry pumps are a great example that represent the company’s commitment to producing heavy and powerful centrifugal pumps. Orion Series horizontal slurry pumps are robust pumping equipment designed for abrasive slurries. Made for the most arduous industrial slurry pumping applications. The horizontal slurry pumps consists of hard metal lined (HM) and rubber lined (HM) pumps.

Featured Highlights:

– Heavy duty grease lubricated bearings in a sealed cartridge. (Double arrangements available)Double sealed w/ V-ring protected lip seal to ensure reliable operation

– -High power transmission design w/ reduced impeller overhang

– Closing front impeller running clearances (optional double adjustment frame)

– Centrifugal seal arrangement

– Even wear design

– Radial or Partial Mixed flow main vanes

– ANSI/ Metric flanges as required for optional flange configurations (on all HM Pumps)

– Front and back expeller vanes

– Wear Resistant castings

The Orion Series horizontal slurry pumps rank #1 in low total cost, low power consumption, long wear life and reliability in operation.

Reach out to our sales team through sales@nwpump.com or call 1-800-452-PUMP for more information.

Feb 1, 2021 | Industrial

Northwest Pump has been a primary distributor for Oberdorfer on the West Coast, and has recently taken on MP Pumps. Gardner Denver is the parent company to both brands and offers a variety of pumps for applications such as agriculture, general industry and Marine. MP Pumps and Oberdorfer by Gardner Denver have been supplying a range of high-quality pumps along with in-depth industry knowledge to customers around the world for years, proving their role as a leader in centrifugal pumps. Learn more on how their pumps can meet your industrial needs.

Oberdorfer and MP Pumps have been committed to designing and developing innovative products to meet the fluid handling requirements of both current and emerging markets. No industry has benefited more from these brands than the Marine Industry. Marine pumps from MP and Oberdorfer centrifugal pumps are ideal in a wide array of Marine applications such a bilge pumping, air conditioning, seawater recirculation, oil change, fuel transfer and more. Many leading marine manufacturers and boat operators have come to rely on MP & Oberdorfer for fuel transfer and conditioning , ballast trimming and oil transfer.

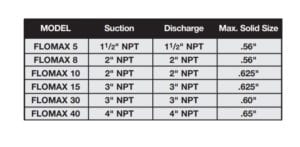

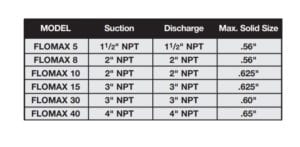

By popular choice, the Flomax series from MP Pumps are commonly used in Marine Applications and are their signature product line. Flomax pumps flows between 100-750 GPM and pressures between 100-230 feet of head. Self-priming and straight centrifugal MP Flomax models come in cast iron, stainless, bronze and aluminum. Options include engine drives, pedestal models and hydraulic drives, and clutch packs.

Northwest Pump carries a complete line of MP Flomax pumps, accessories, repair and replacement parts. For more information about MP Pumps and Oberdorfer by Gardner Denver, please reach out to sales@nwpump.com or call 1-800-452-PUMP.

You can also find Northwest Pump on ShipServ for all you Marine application needs.

Jan 28, 2021 | Petroleum

You have bought your EMV equipment, but now what? Below is a check list of items to mark off your list of to-dos so you are 100% ready for the EMV deadline in April.

Step 1: Schedule you installation

Installation times are getting longer and longer, so be sure to get your installation scheduled asap!

Step 2: Get Financing if you need it

Patriot Capital is offering rates as low as 4.9% for EMV customers. CLICK HERE to get reach out to their staff.

Step 3: Get TCP/IP Connectivity

TCP/IP is standard Internet communications protocols that allow digital computers to communicate over long distances. Be sure to get this installed as well at your site.

Step 4: Let Your Customers Know You Are EMV Compliant

Purchase stickers to put on the pump or signs to put in the window to let customers know that you are EMV compliant.

Step 5: Train Your Staff

Train your staff so they know all the benefits EMV has to offer and why it was so important to the business and for your customers, as well as how the new equipment works.

Need to know stats & Gilbarco lead times

- 450 million dollars in fraud hit fuel dispensers in 2020

- 50% of Americans use contactless payment

- Encore Dispensers: 10 weeks

- FlexPay IV Retrofit Kits: 6 weeks

- Passport Windows 10 Upgrade Kits: 10 weeks

- BRCM Communication Kits: 8 weeks

- DCM Communication Kits: 12 weeks

CLICK HERE for the Gilbarco Resource Page.

SHELL NOTICE OF OUTDOOR EMV MONTHLY NON-COMPLIANCE FEES

The purpose of this letter is to provide notice of potential, monthly non-compliance fees and how they will be assessed. Please be reminded that pursuant to Section 12 of the Shell Transaction Card Guide – and pursuant to a prior written notice to you dated March 25, 2020 – you were informed that wholesalers may be charged non-compliance fees for each non-compliant location until the location becomes EMV compliant.

Accordingly, following the liability shift, Shell will also implement a monthly non-compliance fee for each location not fully operating with EMV as of May 1, 2021. The new fee will begin at $250/month/site on May 1, 2021. On July 1, 2021, the fee will increase to $500/month/site. Each location’s non-compliance fee will be administered to the wholesaler’s account beginning in May and will continue for subsequent months until the location is EMV compliant. Additional fee increases following July 1, 2021, will be subject to future announcement. These fees will help offset additional costs to Shell to maintain and operate two EPOS system platforms until all locations in the Shell network transition to the EMV standard.

For additional questions or assistance on the April EMV deadline, please contact your sales rep/local branch, or you can call our main office at 1-800-452-PUMP, or email us at sale@nwpump.com.

*Northwest Pump is not liable for products to show up before the EMV deadline. Lead times have been pushed out due to COVID-19.

Dec 15, 2020 | Industrial

As of November 2020, NW Pump has become an official distributor for Atlas Copco portable pumps. Altas Copco is a leading manufacturer of rotating equipment for the Industrial and Construction markets. Recently, the Swedish multinational industrial company introduced a line up of NEW PAC H Range Pumps designed with maximize uptime and extended product lifespan.

Product lineup includes:

-PAC H43C

-PAC H64

-PAC H108

The NEW PAC H Range pumps are used for high-pressure industrial applications such as dewatering, quarrying and surface mining. This pump features its ability to handle liquids containing solids of up to 3.5″ in size, increasing the products lifespan and reducing downtime. These high head centrifugal pumps deliver substantial savings towards operational cost and OPEX (Operational Expenditure).

Pac H Range- Portable Pumps-Side

The PAC H Range series features a maximum head size of 500ft and a maximum flow of up to 6400 US gpm. Corrosion free through a fully protected cross-linked polyethylene fuel cell reduces clean up time. Through a fully protected seal equipped with deflector vanes, your pumps seal life last up to 3 times longer. And with compact proportions, the PAC H range allows for easy transportability with up to 3 units on a regular 48 ft. flatbed trailer.

Atlas Copco PAC H pumps decreases repair time by 30% times compared to other products. Made possible by the pumps hinge kit that includes a swing door that allows easy access to the pump’s internal workings and a single bolt to remove the impeller. Through this compact design, customer’s can be assured they can return to operation in a timely manner.

Pac H Range- Portable Pumps- Front

The New PAC H range is available in four models is the best dewatering solution for a wide range of applications. It’s loaded with innovative design features that can help you save money.

Just check the many benefits and and features the PAC H Range pumps have to offer:

– 3 times longer seal life

– Up to 30% Reduced MTTR

-Up to 3 units on a trailer

-Fuel cell is made out of cross-linked polyethylene; giving it strength and making it temperature and environmental resistant

– No metal oxidation; Cleaner fuel lines and less maintenance

-Reduces condensation, increasing the filter lifecycle

-Max Head up to 500 ft.

-Max flow up to 6400 US gpm

-Up to 3.5 in solids handling

For more information about the Atlas Copco brand, please reach out to sales@nwpump.com or call 1-800-452-PUMP.

Nov 30, 2020 | Industrial

We are happy to announce the partnership between Sharpe Mixer and Northwest Pump – providing equipment and engineering services for the advancement in mixing technology. Sharpe Mixers has been a trusted mixing partner since its founding in 1953. The Seattle based manufacturer offers quality engineering, superior products and a wide range of mixer designs.

Sharpe Mixer’s portable stainless steel F-Series stands for optimum sanitary mixers that maintain resistance to deterioration and contamination. This heavy duty portable line is perfect for both small-scale mixing in direct drive alignment where greater shear is required or the gear drive option which is best for larger volumes or higher viscosity fluids.

Sharpe Mixer’s F-Series carries several models including USDA approved stainless steel mixers such as Direct Drive, Gear Drive, and Thrifty mixers. Choose between a clamp, plate, or a flange mount depending on your industries need. The F-Series mixer line has been refined and improved over many years to assure that every component has significant advantages over any other mixers on the market.

F-Series Products we now sell include:

•Direct-drive heavy-duty Portables and F-Series mixers

•Gear-Drive heavy-duty Portables and F-Series mixers

•Thrifty Mixer

Industries include but not limited to:

• Biotech

• Pharmaceuticals

• Food

• Distilling

• Brewing

• Chemicals

• Water and Waste Water

• Biofuels

• Coatings

• And more!

Overall Product Highlights include:

•Direct drive or gear drive

•Commercially available components

•Clamp, fixed or closed tank mounting

•Hyflo hydrofoil

•Available in welded shaft/ impeller assemblies with a no, 4 polish

•Pre-engineered line of USDA approved portable mixers

•Tank sizes up to 5000 gal

•Viscosities up to 15000

Direct-drive Heavy Duty Portable Highlights:

• Standard Nema 56C frame motors are used to assure “off the shelf” availability and a wide range of motor options

• Shaft coupling is protected from corrosion, safely located inside the sealed housing.

• Outboard shaft bearing minimizes whip and vibration.

• A rubber- encapsulated vapor seal protects internal parts

• Alloy mixer housings are powder coated for maximum durability

• Stainless-Steel mounting clamp (guaranteed for life against breakage!)

• Oversize ¾, 1” and 1-1/4” diameter shafts are used for maximum stability and long life

• S.S.316 marine propeller provided standard. Shear discs or other impellers available

Gear Drive Heavy- Duty Portable Highlights:

• Precision helical gearing is hardened and ground for exceptional strength, durability and quiet operation.

• Outboard shaft bearing minimizes whip and vibration

• Wide range of motor options

• Shaft Coupling is protected from corrosion, safely located inside the sealed housing

• Ball and socket mount allows 360 degree rotation and 90 degree vertical adjustments

• Energy –efficient Hyflo 218 impellers pump more for less power. SS316 construction

Thrifty Mixers:

• Adjustable-angle mounting clamp and housing are made of heat-treated aluminum

• Non-proprietary 56C motors. Standard 1-ph models include 10 ft cord with switch and 3- prong plug

• Shaft coupling is enclosed within a protective housing

• SS316 marine propellers furnished standard. Folding blade impellers are available for installation through 2” NPT bungs on barrel mixers

For information on your Sharpe mixer, contact NWP at sales@nwpump.com or call 1-800-452-PUMP.